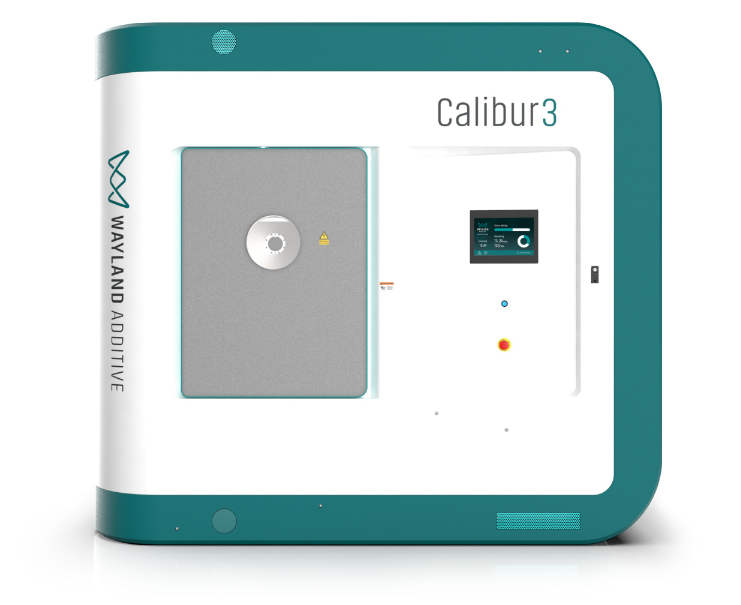

UK-based 3D printer manufacturer Wayland Additive has announced that it will launch its first industrial 3D printer, the Calibur 3, on January 27, 2021. The machine will be the first to feature the company’s NeuBeam electron beam melting (EBM) technology, which promises a number of advantages over existing manufacturing processes. While a full list of technical specifications will be available from January onwards, the first set of commercial printers are expected to ship sometime later in the year.

Will Richardson, CEO of Wayland Additive, states: “Save the date in your diary now. We are in the process of curating an impressive in-person and on-line event which will be of huge interest to industrial sectors that use or are planning to use metal AM for production applications. January 27 will be a pivotal day for Wayland, but also a pivotal day for the industry as they get a first clear view of the opportunities that exist through the use of our NeuBeam technology.”

The advantages of NeuBeam 3D printing

NeuBeam was originally unveiled in April of this year, after Wayland licensed the process from parent company Reliance Precision. It aims to consolidate the best of both laser and electron beam powder bed fusion, and is specifically for production applications. According to Wayland, EBM systems often have issues with charge accumulation, which can limit the range of print parameters and materials compatible with the technology. NeuBeam is reportedly a “charge neutral” process, making it more flexible than its competitors.

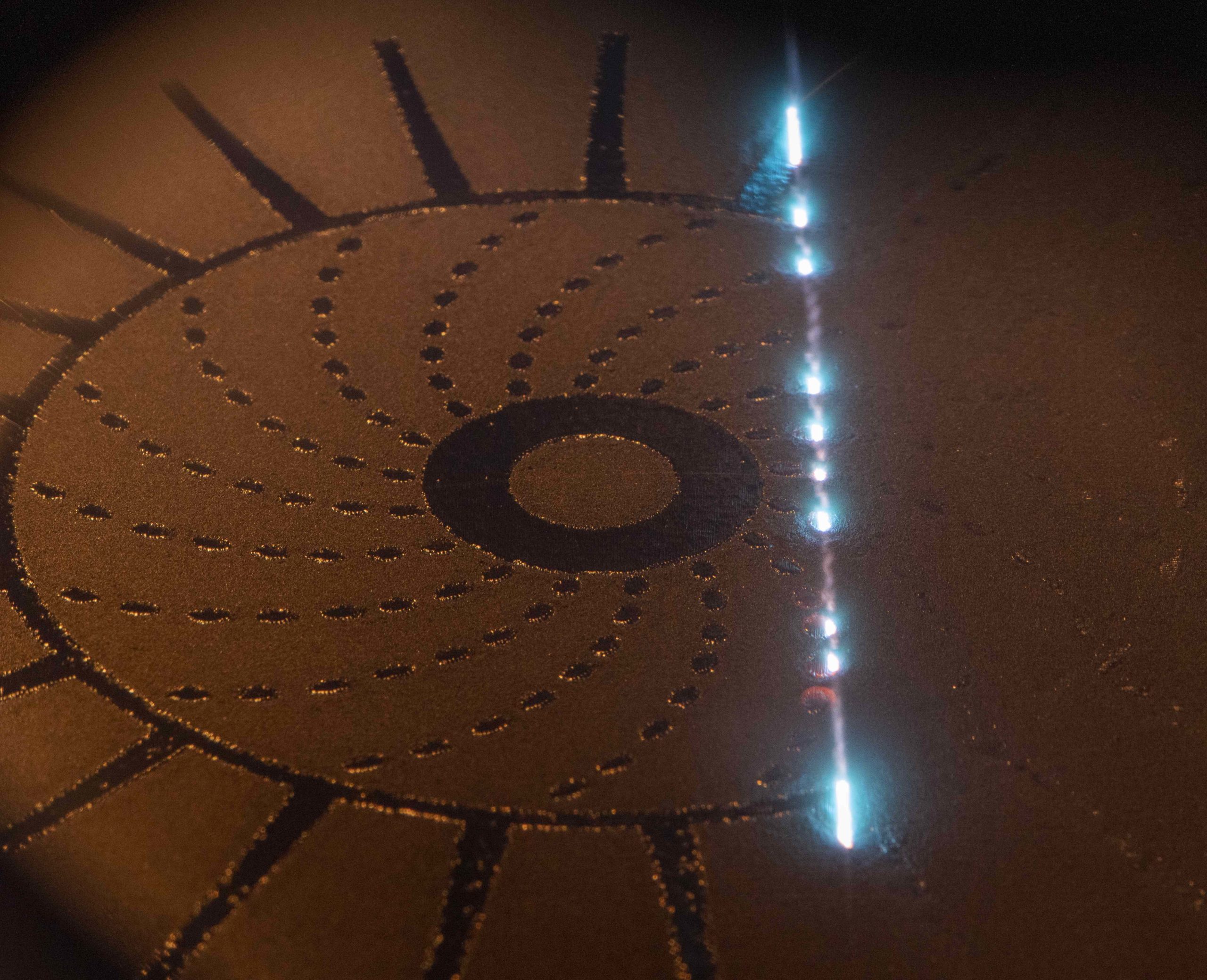

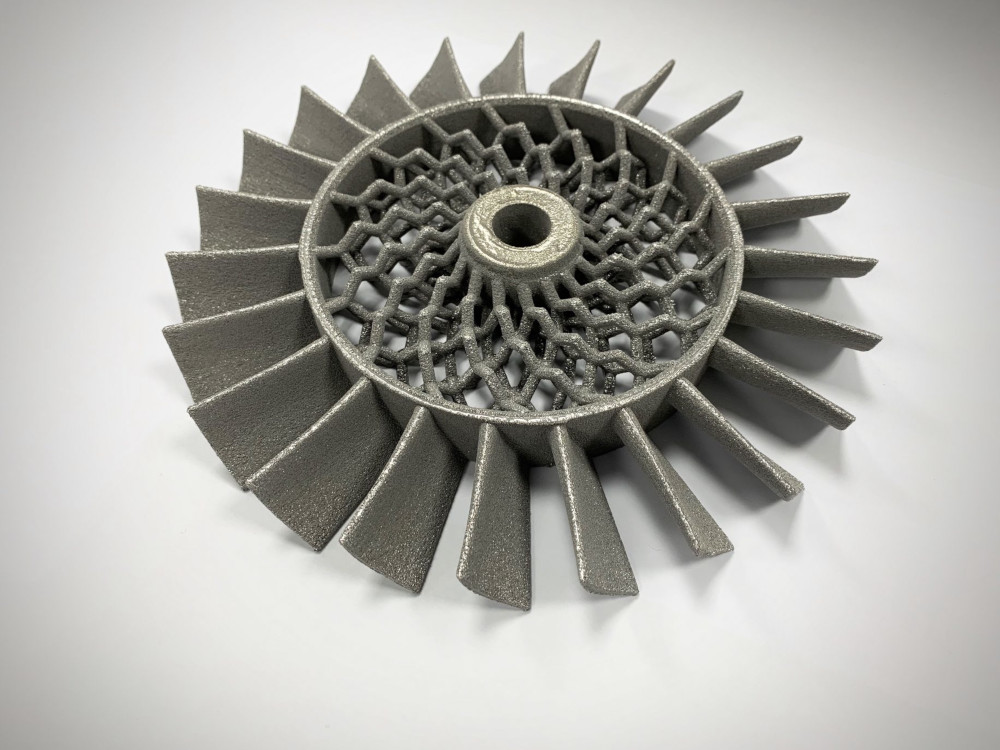

The Calibur 3 has also previously been described as a hot part machine, rather than a hot bed machine. Energy – and heat – is only applied to the relevant sections of the powder bed where the part is being printed. As a result, partially sintered powder is not an issue, so any material unused after the print job can be reclaimed and reused with ease. This makes post-processing less tedious while reducing the overall energy consumption of the system.

Perhaps the boldest claim of the technology is that it can 3D print residual stress-free parts. Residual stresses are a long-standing issue with PBF processes, whereby the constant cycle of heating and cooling caused by the laser/EB scanning results in the contraction of layers. Adjacent layers can end up pulling on each other, forming shear stresses within the part itself. In extreme cases, this can cause the part to fracture and render it unusable. Since the effect is most pronounced on large cross-sections, the residual stress-free printing of NeuBeam could enable large part production on a scale currently not possible.

To top it off, the Calibur 3 also features integrated in-situ part monitoring with individual structured light scanning, electron imaging, and high speed infra-red camera modules. Users can modify process parameters mid-print, and are given full traceability capabilities for every part printed on the system.

Key players in the EBM space

EBM is certainly one of the more niche technologies within additive manufacturing, despite its ability to produce high-strength metal parts. Wayland will be entering a near-monopolized market space, where GE’s Arcam line of printers take the lion’s share of the market cap. In line with this, China-based orthopedic implant manufacturer AK Medical recently added eight GE Arcam EBM Q10plus 3D printers to its fleet. The company cites a rising demand for implants across the country as a result of the rapidly ageing population.

Elsewhere, in India, Wipro3D and the Indian Institution of Science have previously developed an industrial EBM 3D printer that reportedly offers improved thermal management and high part densities. According to Ajay Parikh, Vice President and Business Head at Wipro3D, it is the country’s first printer to feature the powder-based technology.

The 4th annual 3D Printing Industry Awards are coming up in November 2020 and we need a trophy. To be in with a chance of winning a brand new Craftbot Flow IDEX XL 3D printer, enter the MyMiniFactory trophy design competition here. We’re happy to accept submissions until the 30th of September 2020.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Calibur 3 NeuBeam 3D printer. Photo via Wayland Additive.