3D Printing Industry reviews the CraftBot Flow IDEX XL 3D printer.

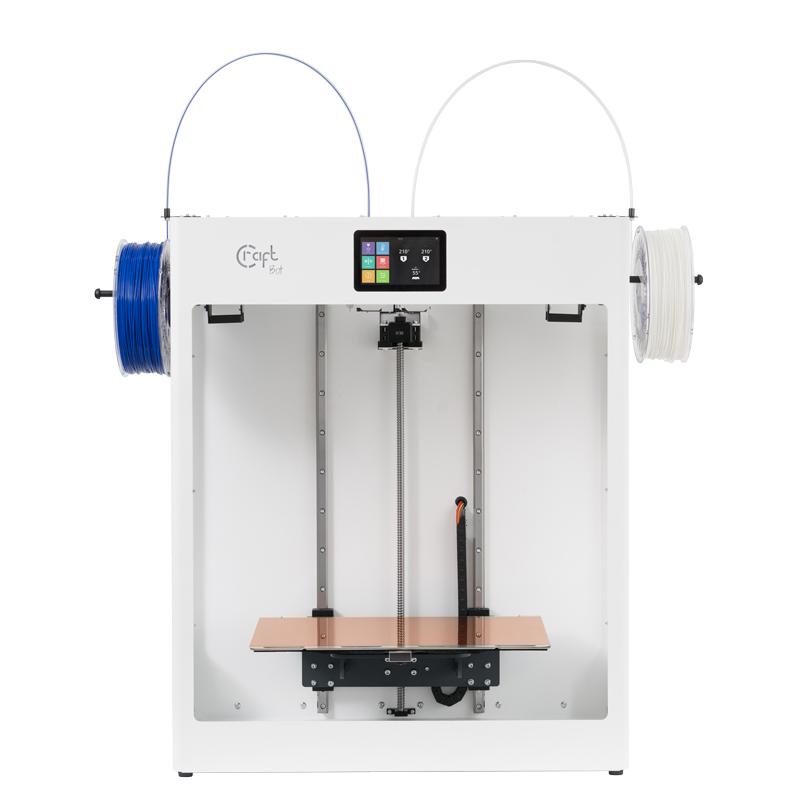

Designed by Hungarian manufacturer Craftunique, the CraftBot Flow IDEX XL is a large-format independent dual extrusion (IDEX) FFF machine. Priced at $3,999, the system is targeted at engineers, designers, architects and artists looking to produce sizable professional-grade prints for functional, artistic or prototyping purposes.

The CraftBot’s large build chamber might not be exactly what you picture when you hear the term ‘large-format’. The design team have opted to focus on model height rather than print bed area, giving the printer a build volume of 425 x 250 x 500mm. This provides users a whopping 56 liters of potential volume to play around with, and the printbed’s area is still nothing to scoff at. Even when compared to the printer’s hulking frame which stands at 635 x 450 x 790mm, it’s clear that Craftunique has made efficient use of space when designing the machine.

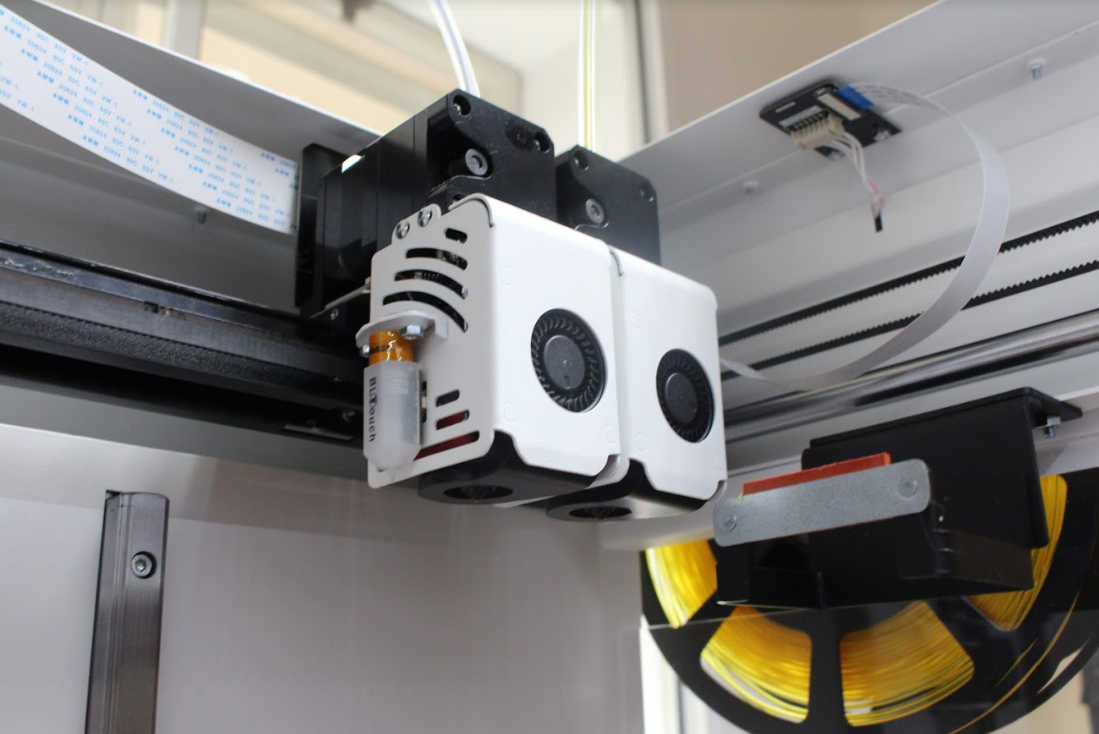

The CraftBot also features an IDEX system, whereby the two all-metal hotends are housed in two separate printheads that are locked together on a gantry in the Y axis but free to move independently in the X axis. A maximum nozzle temperature of 300°C allows the CraftBot to print some of the tougher thermoplastic filaments including ABS, PET-G, PVA, and nylon.

The majority of the printer’s functionality, such as filament loading and unloading, is accessible through the full color 5” touchscreen on the front. Connectivity options include a USB port, Wi-Fi and a 3D cloud. A multitude of quality of life features also make the CraftBot a delight to use, including an in-built camera for remote monitoring and timelapses, and a filament monitoring sensor for print pausing and continuation using the other extruder. The LED status indicator doubles up as a customizable RGB display, making the CraftBot feel right at home in any man (or woman)-cave.

Tall and taller

Where we see many ‘older brother’ printers doubling the area of the print bed, the IDEX XL has instead chosen to double the height of the build chamber over its predecessor, the CraftBox Flow IDEX. The rather unconventional design choice is probably just the thing artistic and architectural professionals are looking for – we bet the CraftBot could print a mean Burj Khalifa skyscraper.

The IDEX XL’s 38kg body is among the cleanest we’ve ever seen at 3D Printing Industry. The open-form powder coated steel frame is bounded by plexiglass sheets on either side, giving us an unobstructed view of the build chamber. Upon inspection of the inner corners, we struggled to find any loose wiring hanging around, leading us to believe Craftunique has a dedicated wire management team at the office. The printer’s two spool holders can be fixed at any point along the top of the left or right sides of the printer for convenience.

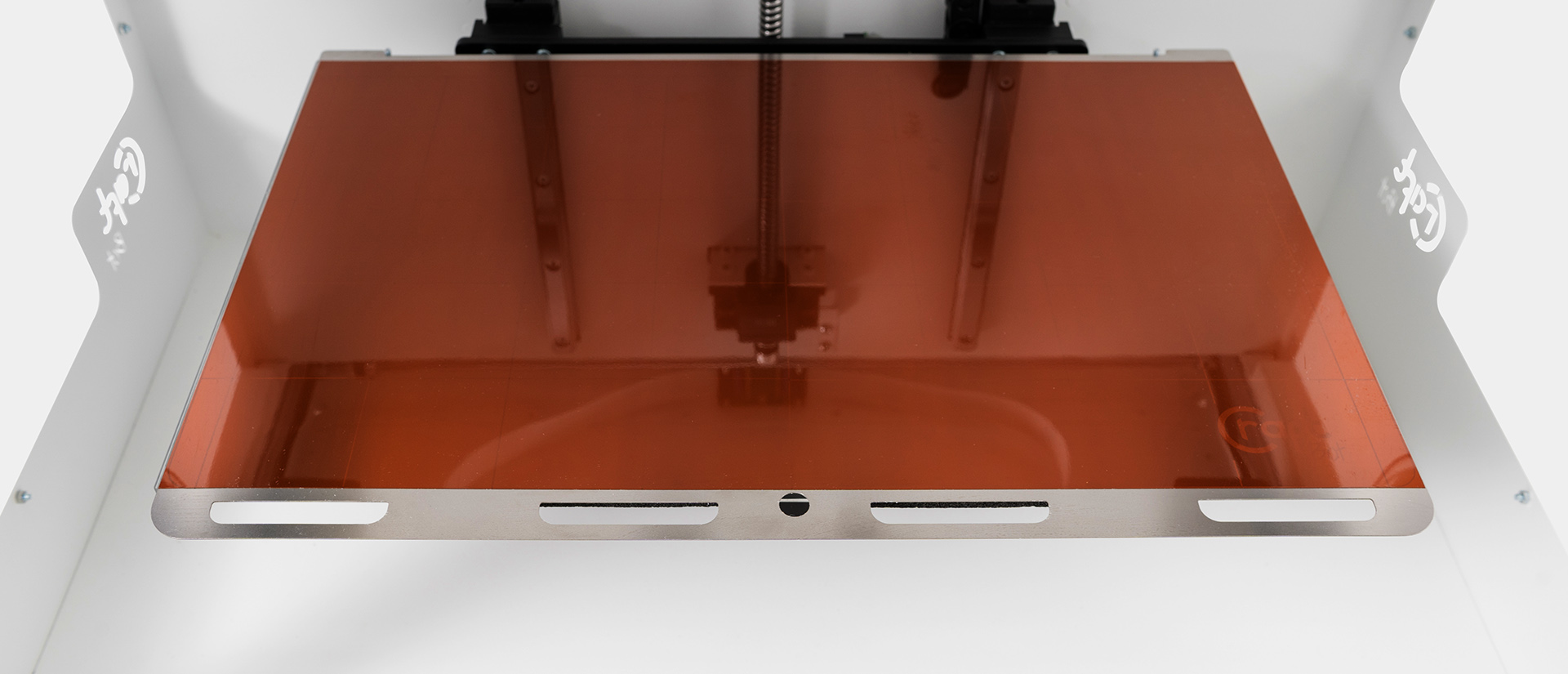

The metal build plate is covered by a detachable magnetic flex sheet, ensuring smooth surfaces on the undersides of prints and easy part removal. The bed is capable of heating up to 110°C, providing additional adhesion for materials that need it. It also travels along a linear rail for added stability.

Bed leveling and nozzle calibration are semi-automatic and take about 10 minutes in total, with the user only needing to turn the wheels under the bed to calibrate it perfectly (with the guidance of the touchscreen). The activation of ‘Wizard Mode’ will see the printer calibrating its own nozzles. Overall, a very intuitive and user-friendly process.

IDEX for the masses

The IDEX system’s main benefit is the ability to use both hotends at once. Since they move independently in the X axis, users are able to make use of the printer’s ‘duplicate’ and ‘mirror’ modes. Using these modes effectively doubles the output potential of the CraftBot, although the two models have to be identical. The duplicate mode creates a carbon copy of a part on the other side of the bed – identical in both size and orientation. The mirror mode creates an identically sized part on the other side of the bed but it is mirrored down the center of the build area. As the weight of each individual printhead is reduced due to only housing one hotend, they are both able to travel a little faster, resulting in shorter print times.

The CraftBot accepts filament of diameter 1.75mm, and extrudes through a nozzle of diameter 0.4mm. The printer’s maximum print speed is 200mm/s and the finest layer height is a respectable 50 microns.

CraftWare slicer

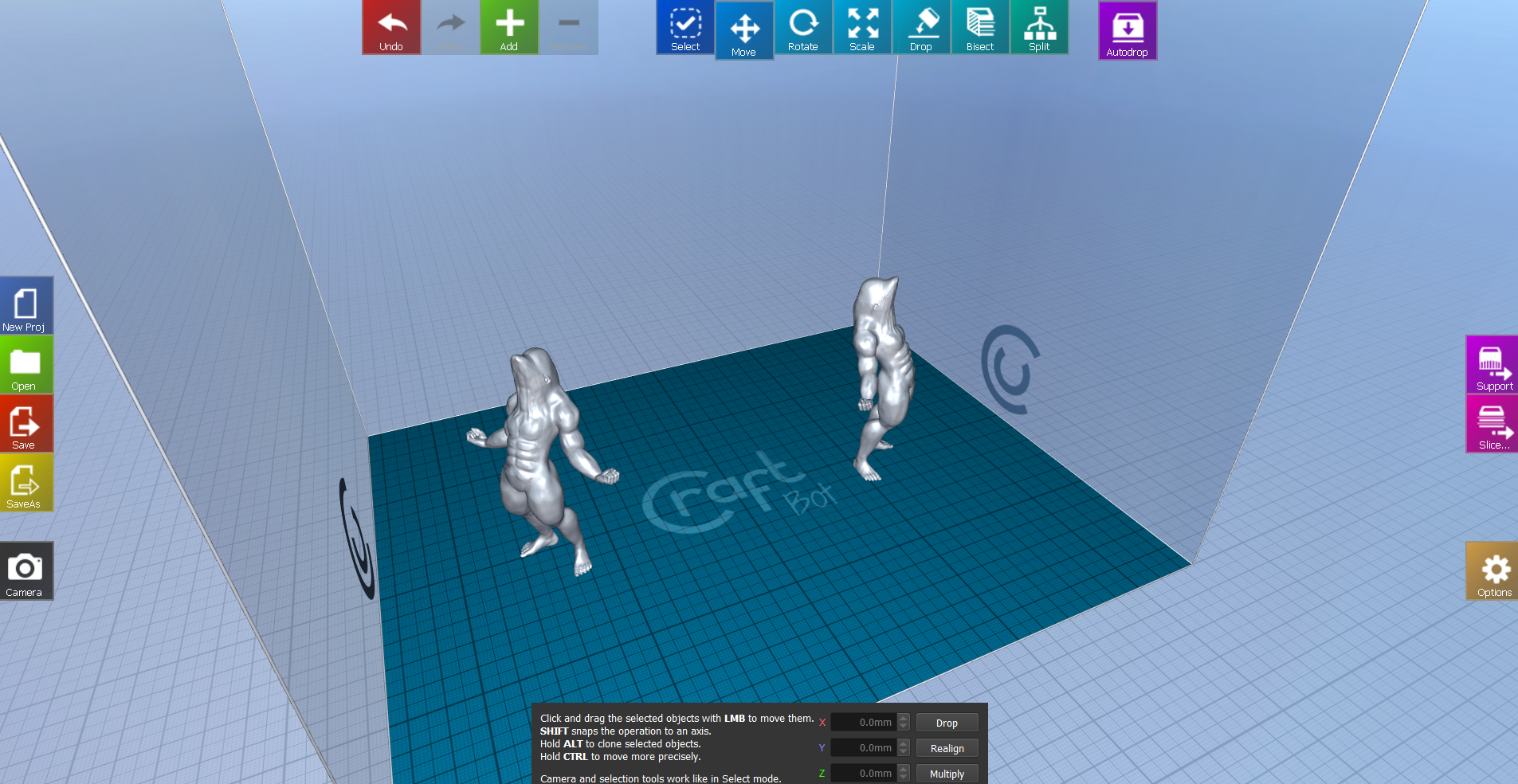

Craftunique provides its own slicing software for file preparation on the CraftBot – CraftWare. It’s worth noting, however, that the printer is compatible with a multitude of open-source slicers such as Cura and Slic3r, and also with the Simplify3d slicer. The first thing that pops out when you load up CraftWare is the abundance of vibrant colors on the screen, it certainly doesn’t shy away from using the whole palette to color-code its functions.

As for the functionality, it’s not much different from most slicers on the market. You load up a 3D model, translate, resize, rotate, support, and export a gcode. The basic functions are intuitive enough that a beginner could pick it up after fiddling around on the menus for a few minutes. For 3D printing veterans, the ‘advanced user’ window grants access to a number of more sophisticated parameters such as temperatures, speeds, and infills. We initially found this advanced mode a little tricky to get to grips with, however. For example, it’s not entirely clear how the slicer handles infill or what the difference between the various options is.

Users also have the option to make use of the printer’s web-based 3D cloud for print management. A well-thought-out UI and menu customizability makes the cloud a delight to use. The CraftBot also lets users modify a few of the more simple parameters like temperature once the print has already begun – a thoughtful and welcome addition.

Benchmarking the CraftBot Flow IDEX XL

It’s time to see what the CraftBot is really made of. Our comprehensive testing regime is designed to push the limits of the printers subjected to it, giving you an overview of everything the system can (and can’t) do.

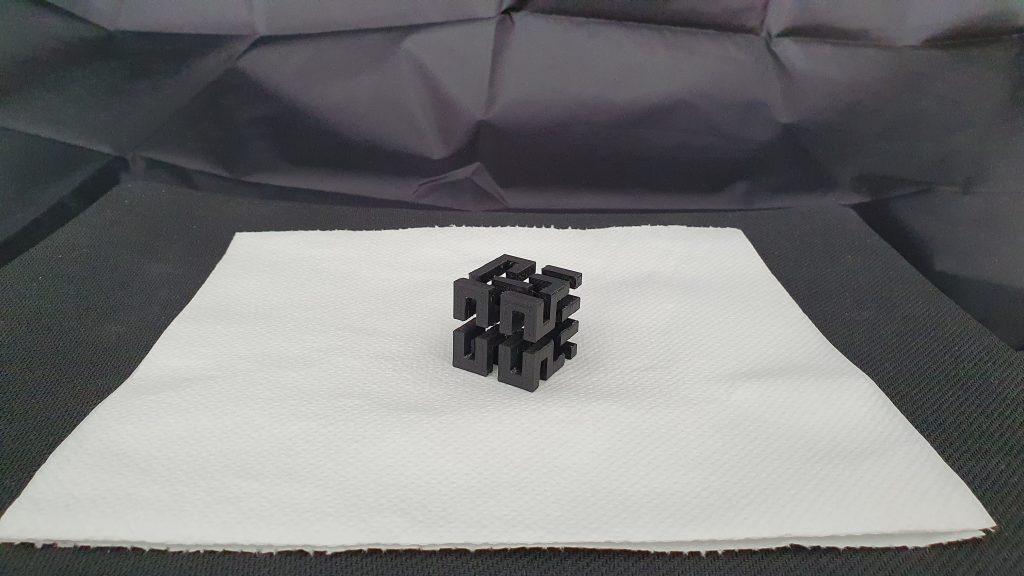

We started off by printing a set of mechanical assemblies on the CraftBot – a nut and bolt assembly and a differential gear system. These tests are good for determining the dimensional precision of a printer as they will only assemble easily and operate smoothly with tight tolerances.

All in all, both systems were printed successfully. The nut and bolt screw together with ease and there is very little play in the assembly; it could definitely be used in practice as a functional part. The differential gears have a very high surface quality but there are some minor defects in the contact zones caused by support scarring. The mechanism still works well and frictional resistance is minimal.

We noticed the slicer had some difficulties in generating automatic supports on the more complex areas of the differential gear system. It was initially over-supported so we had to remove some of the unnecessary connections and revise where the supports should be. Once printed, we found the supports to be quite difficult to remove, resulting in moderate scarring. In this case, it turned out to be unproblematic but may cause issues in very tolerance-sensitive parts.

We then put the CraftBot through the retraction test, which is a measure of the quality of the system’s extruders. The test consists of nine spikes arranged in a grid-like formation. If the extruders aren’t able to successfully hold back the molten PLA while traveling between the spikes, we would have some unsightly stringing on our hands.

Luckily, it didn’t come to that. The retraction ability of the CraftBot is pretty much perfect and there was no stringing whatsoever between the spikes. A resounding success!

Next up was our large-scale Renaissance sculpture. This test was designed to determine how the printer handles long prints (five days for this one), how the printer handles tall prints (495mm), and how well the filament monitoring sensor actually works (you can bet we burned through a few spools).

The result? A print worthy of da Vinci himself. The curves were smooth and the layer lines were virtually invisible. With taller prints, we tend to see the quality deteriorating as the bed moves down the Z-axis due to increased inertia caused by vibrations throughout the printer’s frame. The CraftBot’s sturdy steel frame did a pretty good job of dampening the vibrations, so the quality remained very high throughout the print. The filament sensor also paused and resumed the print at precisely the right locations, making it appear all too seamless.

Obscure material tests

What good is a 300°C nozzle if it can only manage PLA? Our PET-G + nylon test also gave us a chance to try out the printer’s dual extrusion mode. The dual-material container came out great. The difference between the two colors at the interface zone is crisp and the whole structure feels very solid, almost like it’s made of one material.

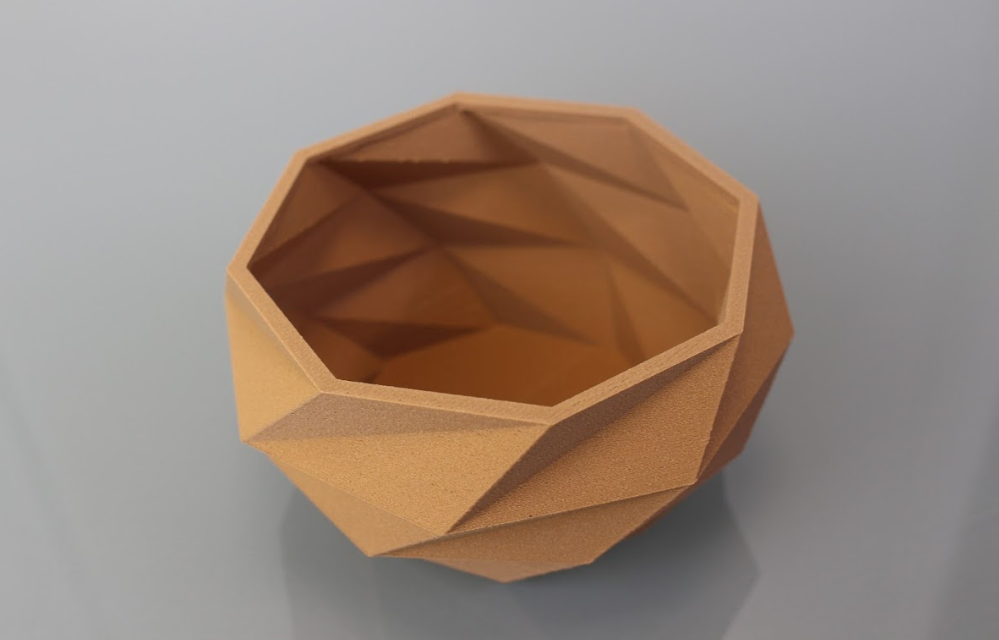

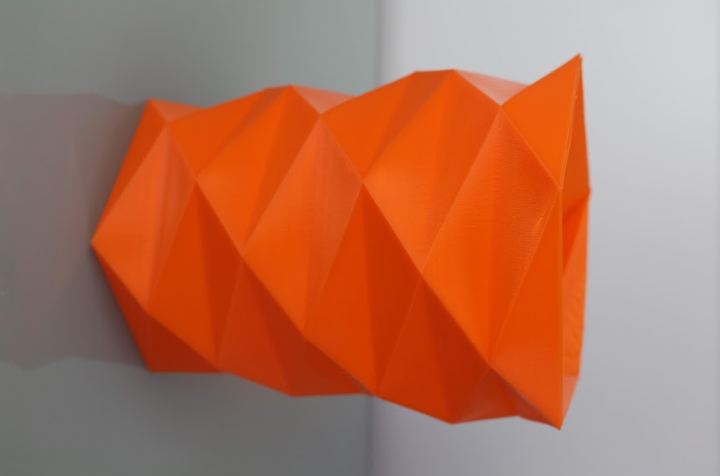

We then printed a set of tessellated containers in wood PLA and Flex filament. We saw no stringing or warping on any parts of either container. The Flex vase even returns to its original shape after significant deformation.

Finally, we gave water-soluble PVA supports a whirl on the CraftBot. The print turned out to be very clean, with the PVA supports placed precisely in the relevant areas. After submerging the print in water, the model emerged with minimal support scarring after virtually no post-processing.

The verdict

Craftunique has done something very special with the Flow IDEX XL. A plethora of carefully designed features make this hidden gem a fantastic large-format 3D printer for professionals. The print quality is just what you’d expect from a professional-grade machine and the colorful slicer works to guide you through the process. One of the only real weaknesses of this printer is the physical support material – it’s consistently difficult to remove. Perhaps the Craftunique team can revise the default parameters associated with automatic supports on the CraftWare slicer to make supports more prone to peeling off. That being said, the printer does everything else right, and we had a blast using it.

As with many of Craftunique’s 3D printers, the Flow IDEX XL comes with a five-year warranty. The company will also be releasing a dome and lockable door attachment for the printer at the end of May, giving users the option of enclosed operation – adding functionality and a level of customizability to the system.

Buy the CraftBot Flow IDEX XL here.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the CraftBot Flow IDEX XL 3D printer. Photo via Craftunique.