In this article, we review the Creaform HandySCAN 700|Elite. Part of the HandySCAN 3D|SILVER Series, this high-end product offers portable and repeatable metrology-grade 3D scanning for industrial-scale engineering applications.

Creaform is a leading manufacturer of 3D scanning and measurement equipment, and a provider of high-quality engineering services.

Founded back in 2002, the Québec-based company boasts a global reach, with customers in over 75 countries. Creaform offers a range of professional-grade 3D scanners within its HandySCAN 3D series.

Prices for Creaform’s Silver Series Scanners start at $22,445. Prospective customers can find more information via the official Creaform website.

Key features of the HandySCAN 3D|SILVER Series

Targeted towards professional engineers and technology companies, Creaform’s HandySCAN 3D|SILVER Series 3D scanners are optimized for product development and reverse engineering applications.

Operating with 7 blue laser crosses, the HandySCAN 700|Elite is advertised as offering accuracy of up to 0.030 mm, and volumetric accuracy of 0.020 ± 0.060 mm/m. This volumetric figure can be improved to 0.020 ± 0.015 mm/m when used in conjunction with Creaform’s MaxSHOT Next Elite 3D photogrammetry system.

Offering a scan area of 275 x 250 mm, users can achieve measurement resolutions of 0.050 mm at a rate of 480,000 measurements per second. Creaform recommends the scanning of parts measuring between 0.1 meter and 4 meters, making the HandySCAN 3D|SILVER Series well-suited to a wide range of object types and use cases.

High-quality, portable 3D scanning

HandySCAN 3D|SILVER Series 3D scanners are highly compact and portable. With a weight of 0.85 kg and dimensions of 77 mm x 122 mm x 294 mm, the HandySCAN 700|Elite is small enough to fit into a suitcase. This makes it an ideal option for users conducting on-the-go 3D scanning in a range of work environments.

The HandySCAN 700|Elite features two cameras and a class 2M blue light laser with seven laser crosses plus one line. As such, it can successfully scan most material types with little difficulty. The camera shutter speeds of all HandySCAN 3D|SILVER Series 3D scanners can also be manipulated to suit different object types, allowing users to optimize them for parts ranging from vehicle panels to small gear components.

Our Creaform 3D scanner came well packaged in a custom hard case, and was shipped with a number of accessories including all necessary power supply and data cables, target stickers, calibration board, cleaning cloth, and sticker remover. The scanner and its accessories all fit neatly into the provided carry case.

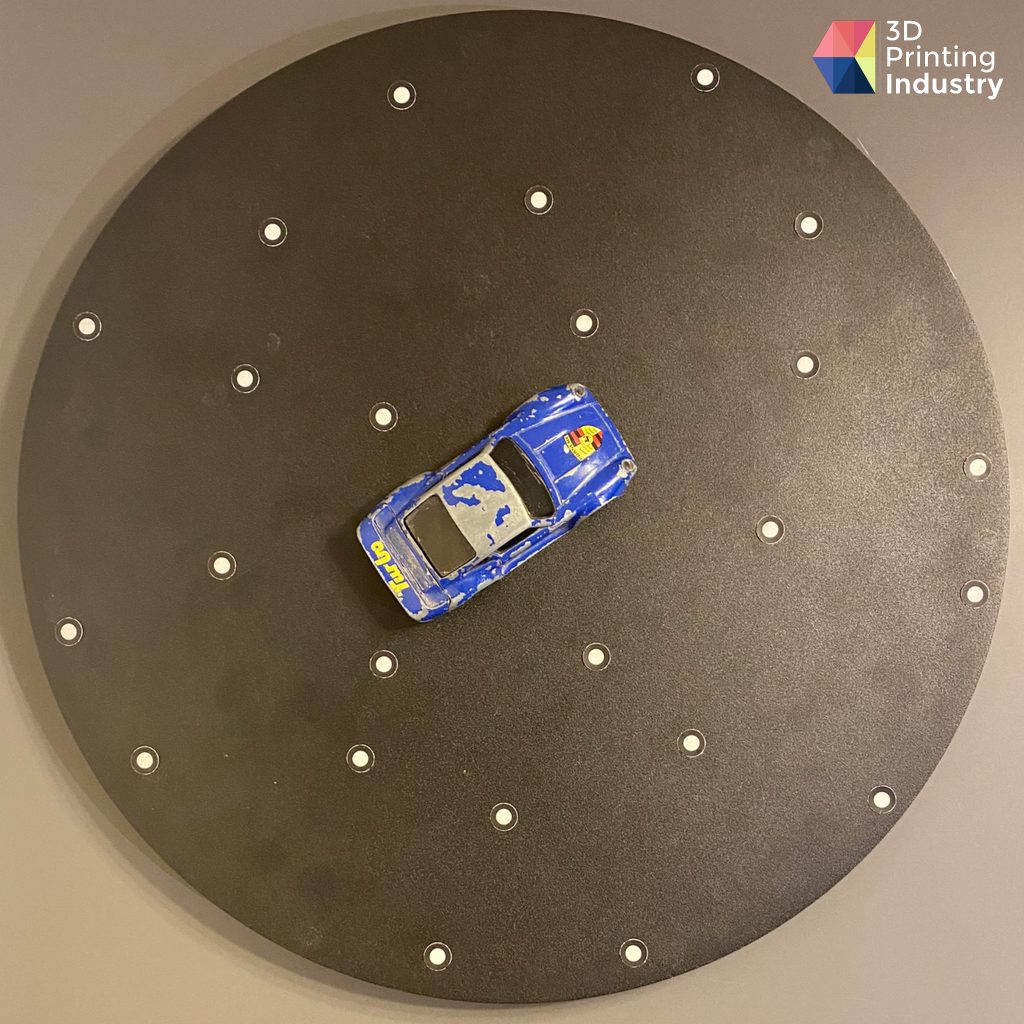

We also received a large manual turntable, which can be used when working with parts too small to accommodate calibration stickers. The turntable can be purchased separately from the Creaform online store.

Overall, we feel the quality of the scanner to be especially high. The handle is very ergonomic and is comfortable to hold, the scanner is lightweight and can be easily manipulated during the 3D scanning process.

The 3D scanner’s case, kit contents and turntable. Photos by 3D Printing Industry.

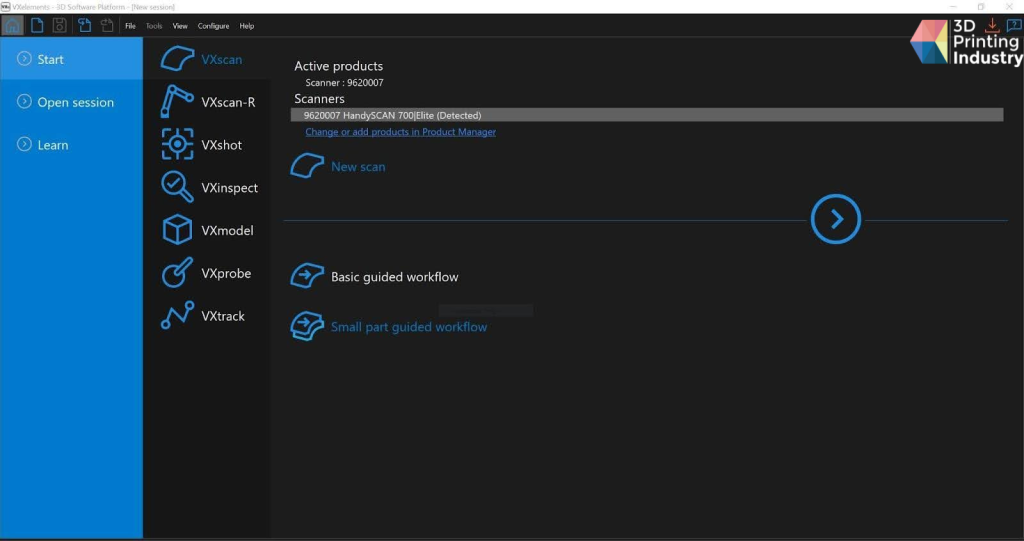

3D scanning with VXelements

During our testing, we used Creaform’s proprietary VXelements software. Thanks to its intuitive UI, we found this platform easy to operate. In our testing, we used the software’s VXscan, VXmodel & VXinspect modules, which worked perfectly with no bugs or errors.

Prior to scanning, the Creaform HandySCAN 700|Elite must be calibrated using a calibration plate, which features 42 reference targets. The calibration process is straightforward and requires the user to move the scanner to 14 reference positions.

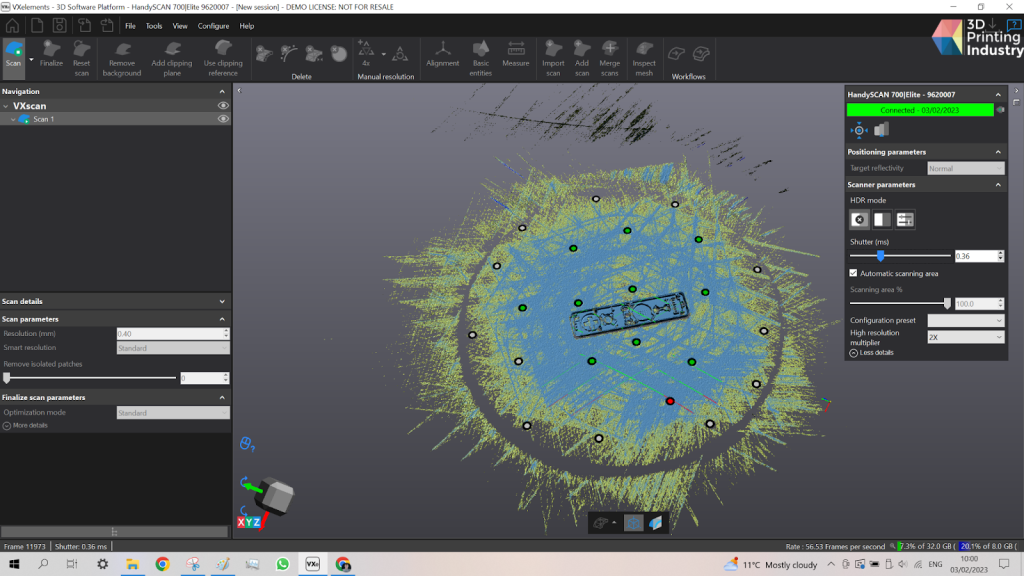

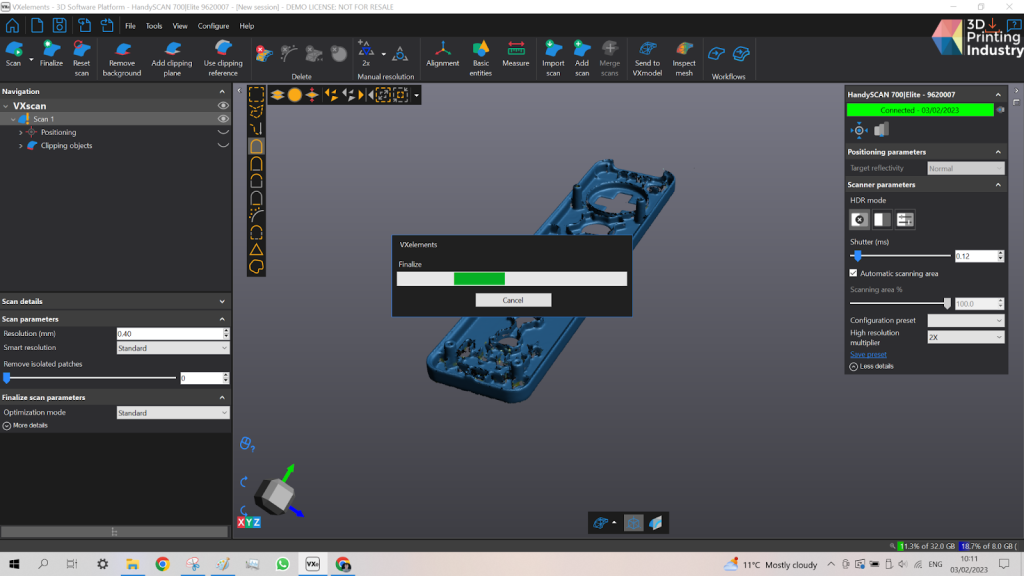

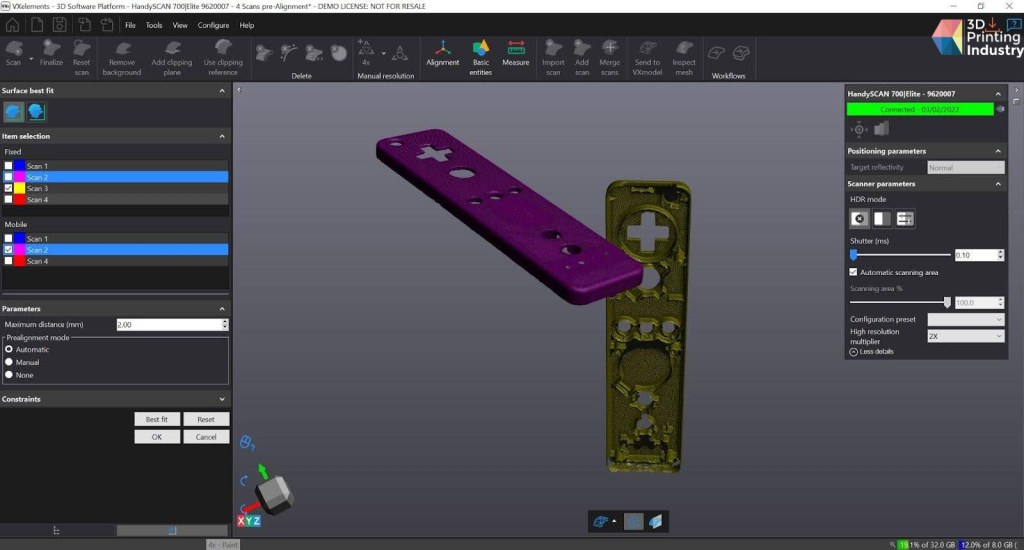

VXscan was used for the calibration, setup, and 3D scanning stages. The 3D scans were then merged and imported into VXmodel for processing. This included cleaning and editing the mesh files, ready to be exported.

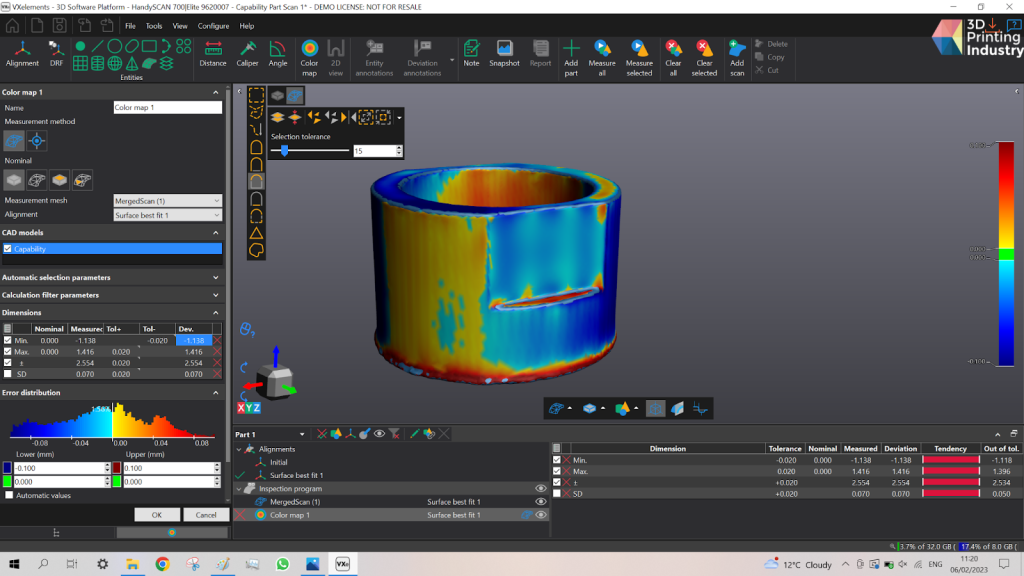

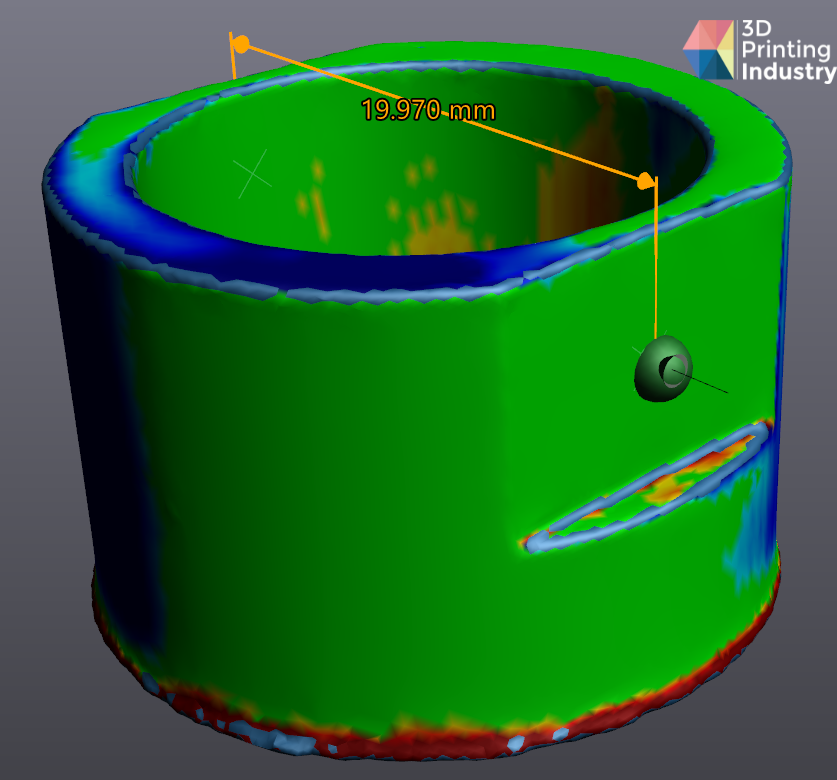

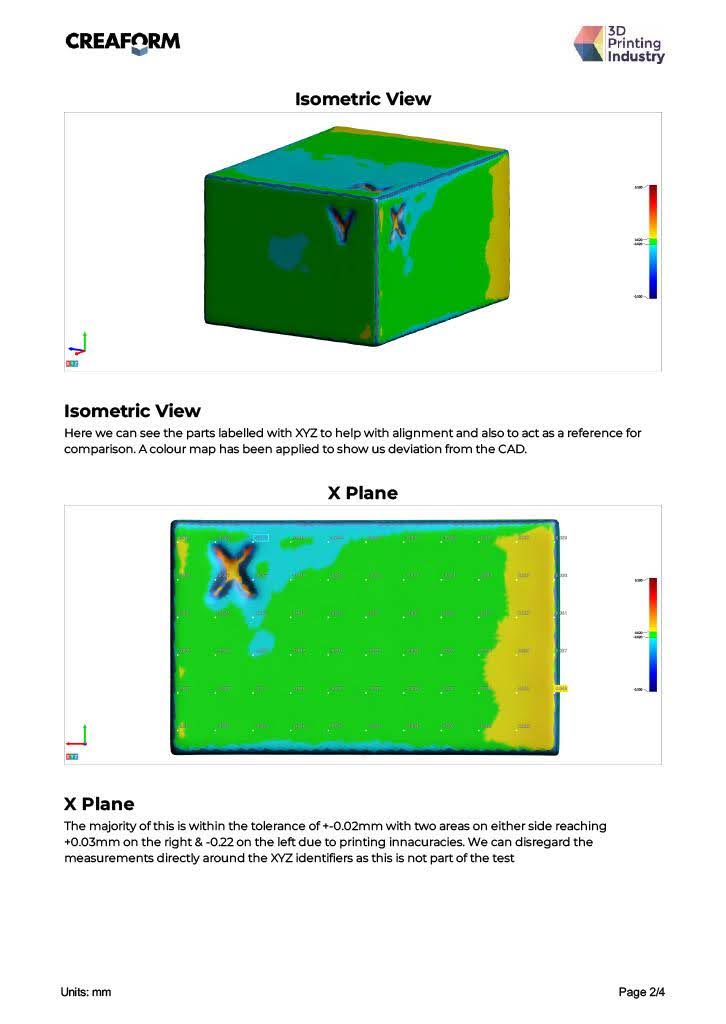

VXinspect was then used for its quality control and analytics capabilities. Here, we found the colormap tool to be particularly noteworthy. This feature uses a light spectrum to visually highlight any deviations of the 3D scan from the original part dimensions. Additionally, the module’s Reports feature was useful, enabling all notes and snapshots to be easily arranged in a PDF document for external viewing.

User interface of VXelements’ VXscan, VXmodel, and VXinspect modules. Images by 3D Printing Industry.

Accuracy testing

To assess the accuracy of the Creaform 3D scanner, our team completed a 3D scan of a 3D printed reference block. The measurements of the scanned model were then compared with those of the physical part within VXinspect. We found the color maps to be highly useful for this accuracy assessment, as they clearly showed each aspect of the scanned part and its dimensions.

Ultimately, the results of this test highlighted the high level of accuracy offered by the HandySCAN 3D|SILVER Series. When compared to the measurements, the 3D printed part possessed minimal deviations of 0.007 mm for the X-axis, 0.004 mm for the Y-axis, and -0.036 mm for the Z-axis.

These results confirm that the 3D scanner can be reliably used for rigorous accuracy testing. Moreover, we feel confident that it is well suited for use within industrial settings where high 3D scanning accuracy and precision are required.

Application tests

Our team next conducted a number of application tests to assess the performance of the HandySCAN 700|Elite with real-world use cases.

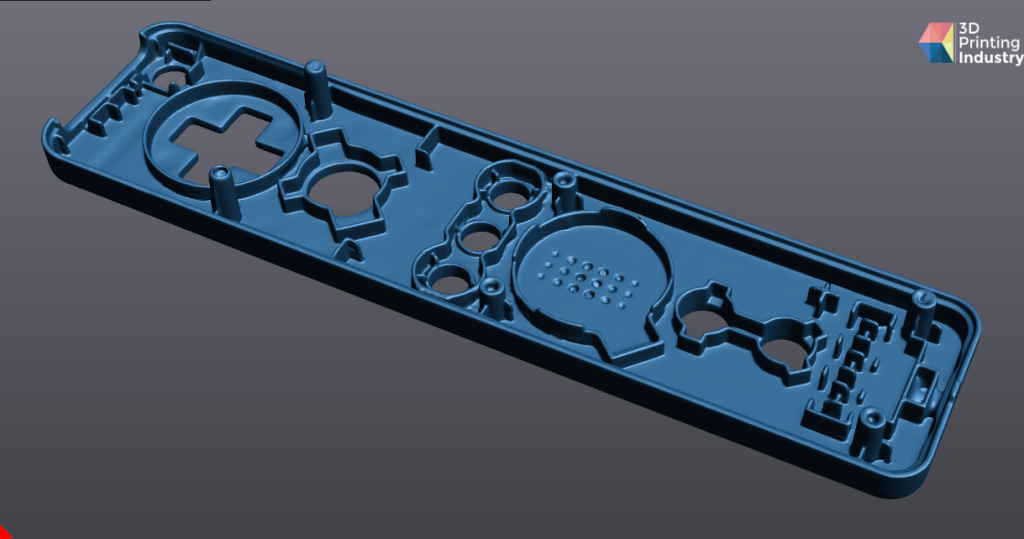

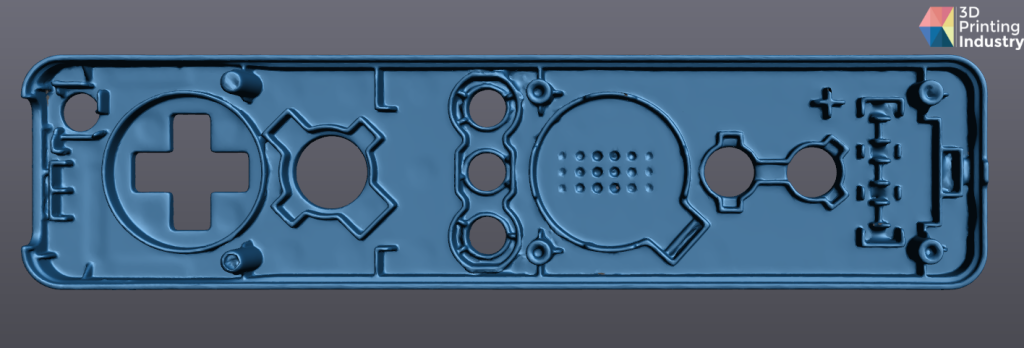

Firstly, we used the 3D scanner to replicate a cover component of a video game remote control. This component includes a lot of internal ribs and injection molding features, which posed a good challenge for the 3D scanner.

Video game remote 3D scan results and scanned part. Images and photos by 3D Printing Industry.

Our team was extremely impressed by the results of this test, as the 3D scanner successfully captured all of the key details of the part. We completed five scans which were then merged, edited, exported to an STL file, and 3D printed on a resin system. The 3D printed component was an almost perfect match of the original, and fit well onto the remote control body.

3D Printed part on the video game remote controller. Photos by 3D Printing Industry.

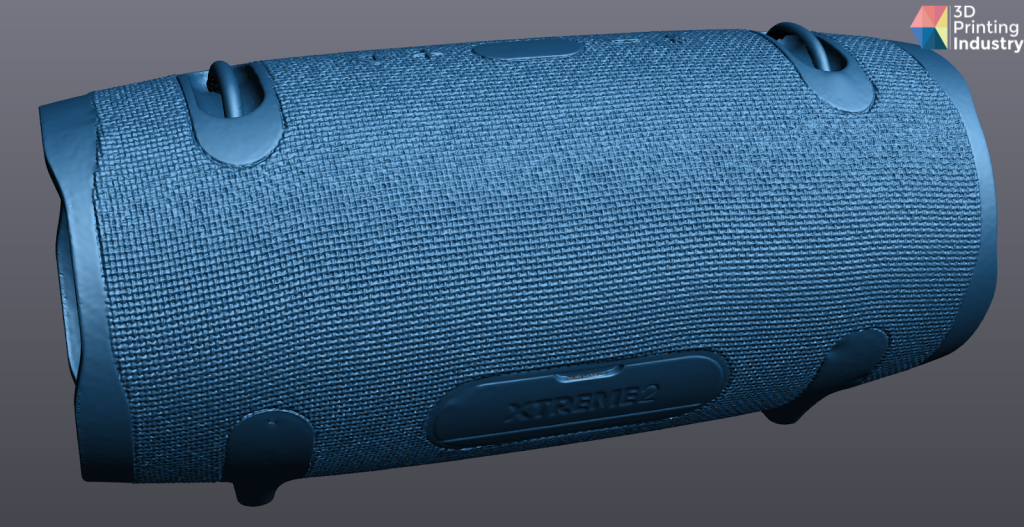

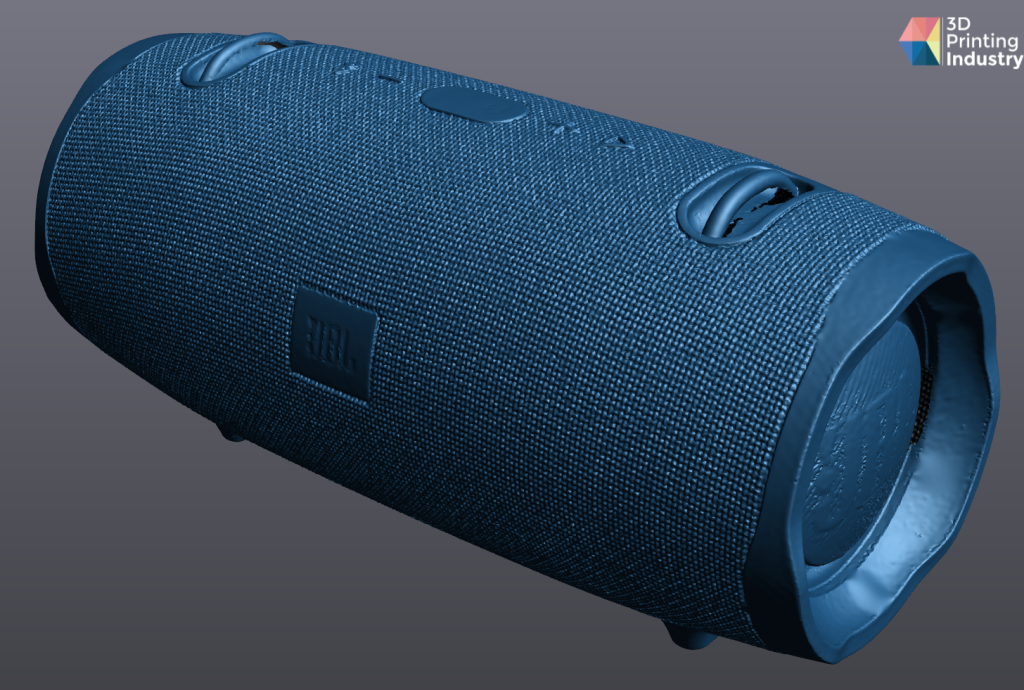

We next conducted a 3D scan of a Bluetooth speaker, a good test of the HandySCAN 700|Elite’s texture quality and ability to handle larger parts placed on the turntable.

This test was also impressive, successfully capturing the weave on the speaker with impressive detail. Completed at 0.2 mm resolution, the 3D scanner successfully picked up the translucent parts on the speaker’s body. The combination of target stickers on the object and turntable worked well, enabling the 3D scanner to keep track of the speaker when the turntable was not in direct view.

Bluetooth speaker scan results and scanned object. Images and photos by 3D Printing Industry.

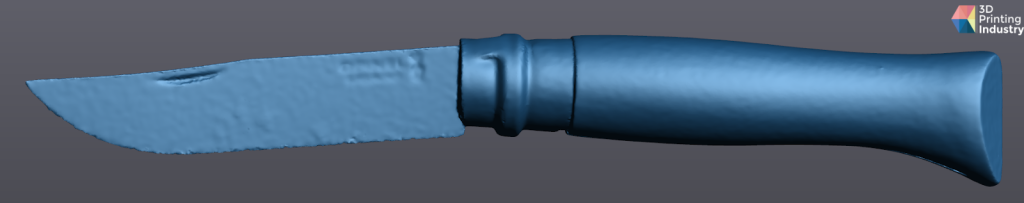

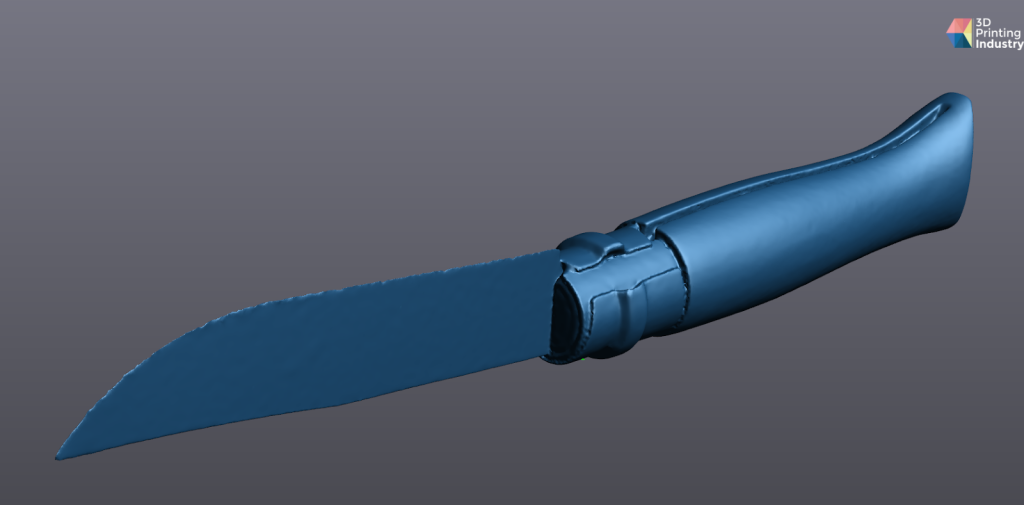

To assess how the 3D Scanner handles sharp and pointy surfaces, we next completed a 3D scan of a foldable knife. The results were again impressive, with the HandySCAN 700|Elite successfully picking up the ageing on the blade. The knife’s sharp point was also of a good standard, highlighting that this 3D scanner can be used for accurately recreating sharp objects.

Knife scan results and scanned object. Images and photo by 3D Printing Industry.

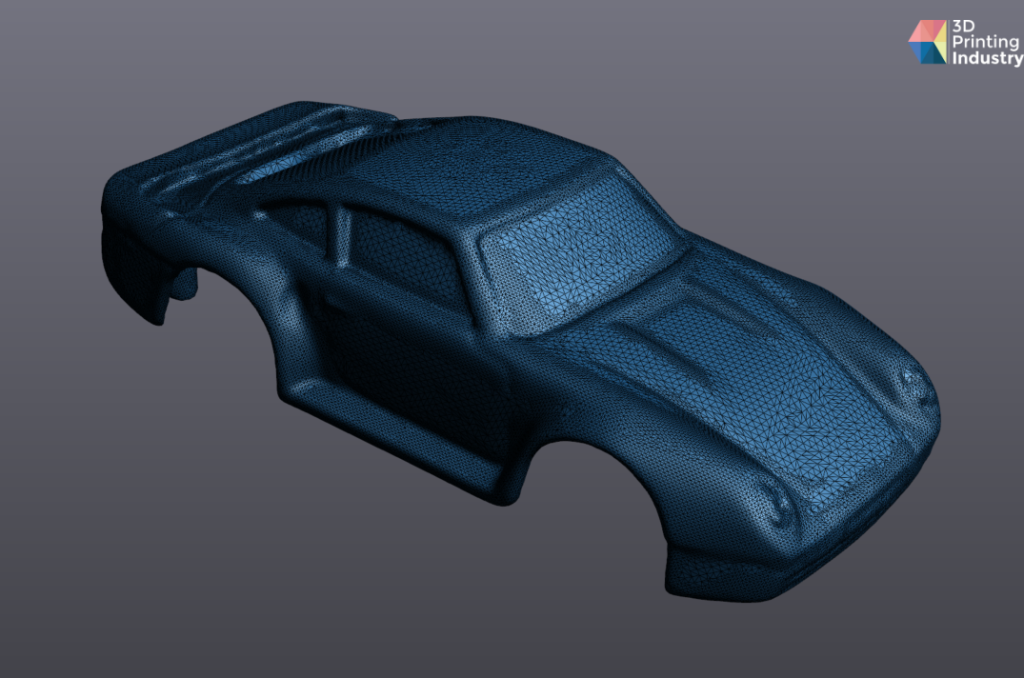

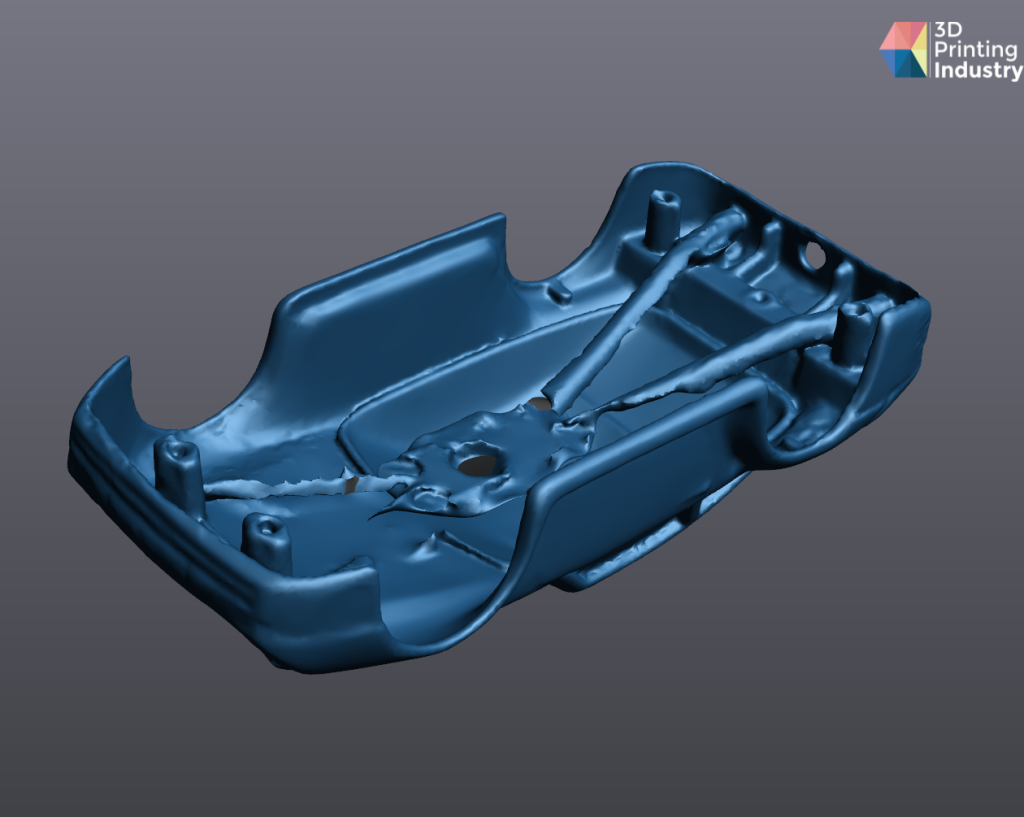

To further assess the 3D scanner’s ability to work with multiple materials, we scanned the shell of a toy car. The body of this part was made from blue-painted zinc alloy, the windows were translucent black, and the headlights were made from clear transparent plastic. Generally, 3D scanners struggle to fully capture transparent materials, as there is no clearly defined surface for the light to reflect off.

Interestingly, although limited in detail, the Creaform 3D scanner successfully picked up more of the transparent material than we had initially anticipated. The translucent black windows also came out well, despite requiring a higher shutter speed than the rest of the object. Overall, the 3D scan produced a nice mesh model which, with some cleaning and editing, could be used to accurately reproduce the original part.

Car shell Scan results and scanned object. Images and photos by 3D Printing Industry.

Next, our team conducted a 3D scan of a Dewalt drill, which served as a good test of the 3D scanner’s ability to capture a number of complex angles and surface features. Ultimately, this test came out well, successfully capturing the part’s details and surface text. Three scans were conducted, which were aligned to create the final merged model.

Dewalt Drill scan results & scanned object. Image and Photo by 3D Printing Industry.

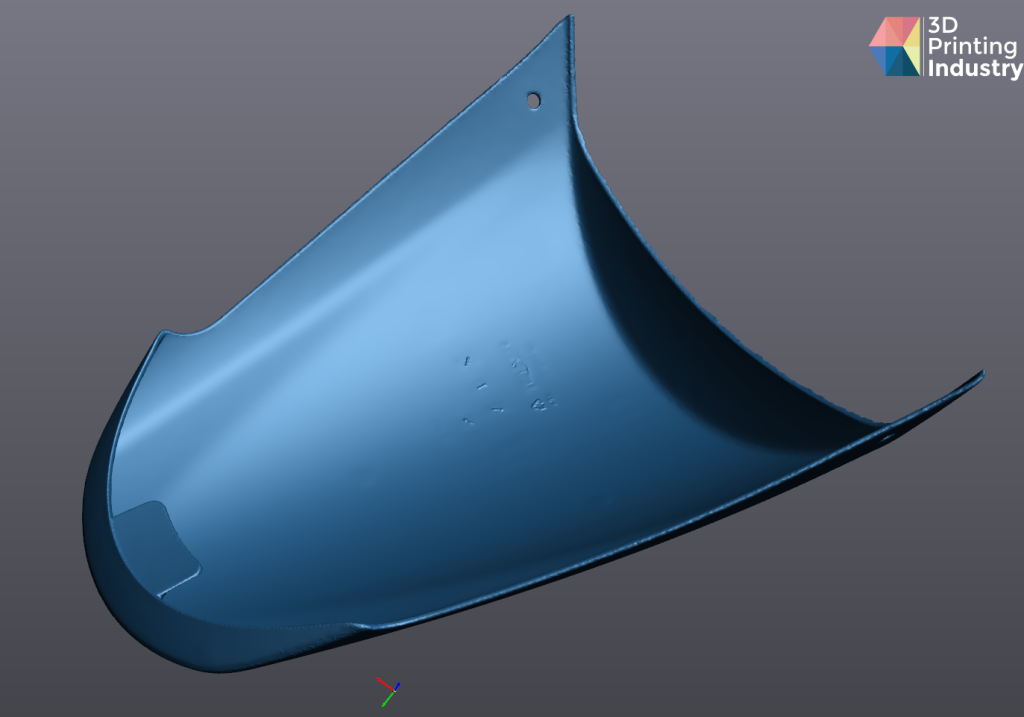

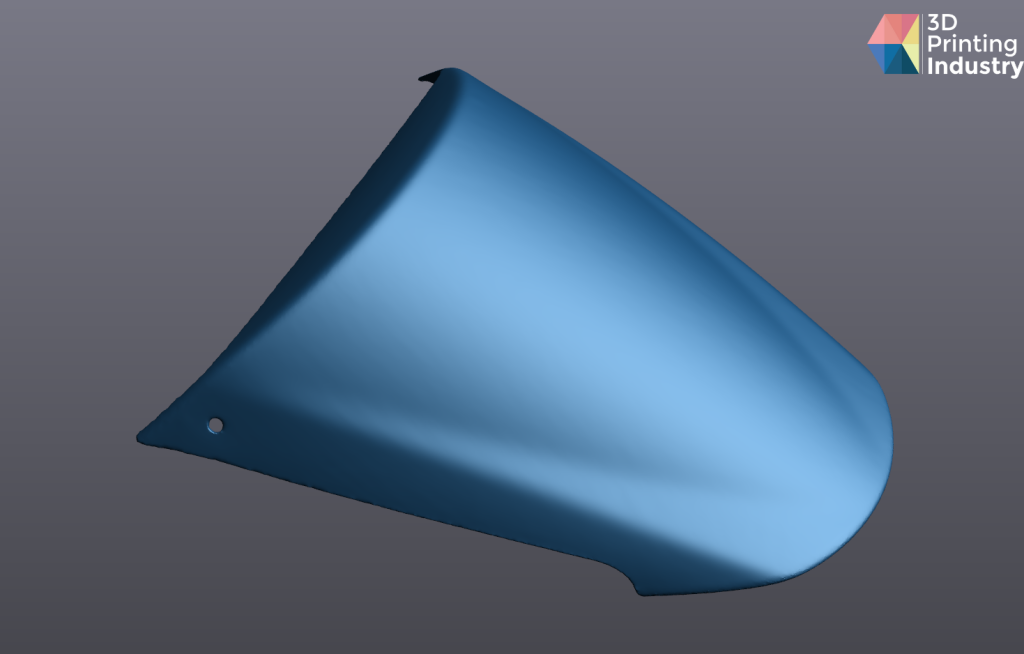

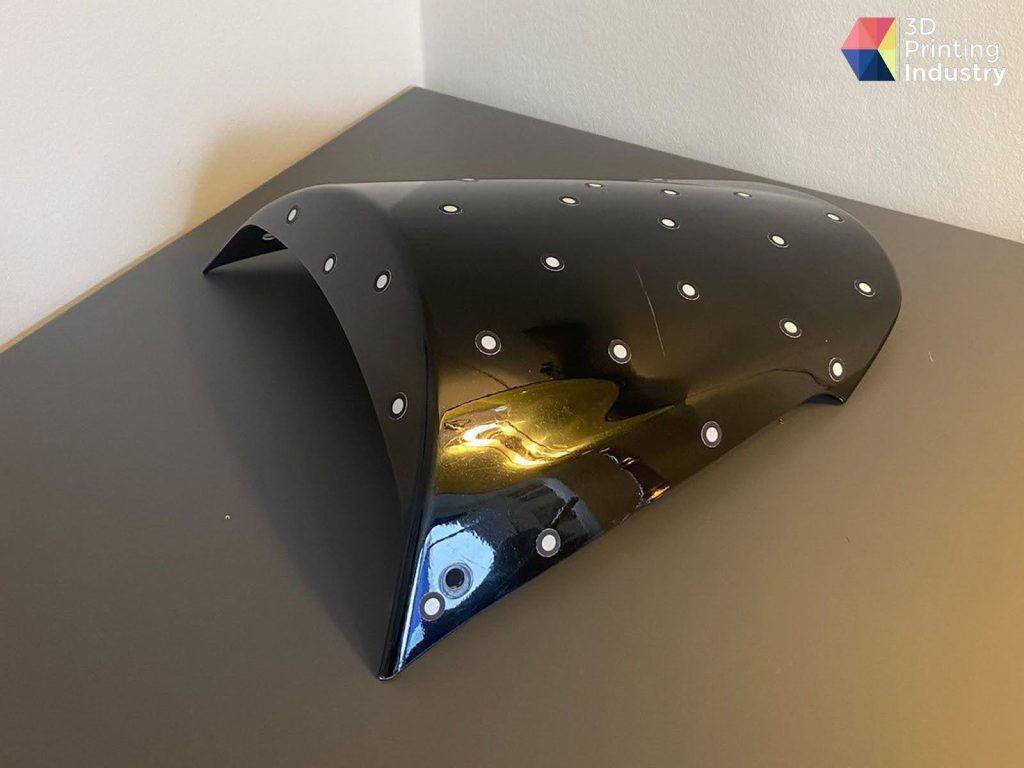

To assess the use of the 3D scanner for reverse-engineering applications and shiny black surfaces, we used a large motorbike seat panel. Too large to be placed on the turntable, we covered this component in target stickers to help the HandySCAN 700|Elite pick up its location. The completed model came out perfectly and required very little cleanup within the software. The 3D scanner is certainly well suited to capturing large objects for reverse engineering or spare part production applications.

Motorbike seat panel scan results and scanned object. Images and photo by 3D Printing Industry.

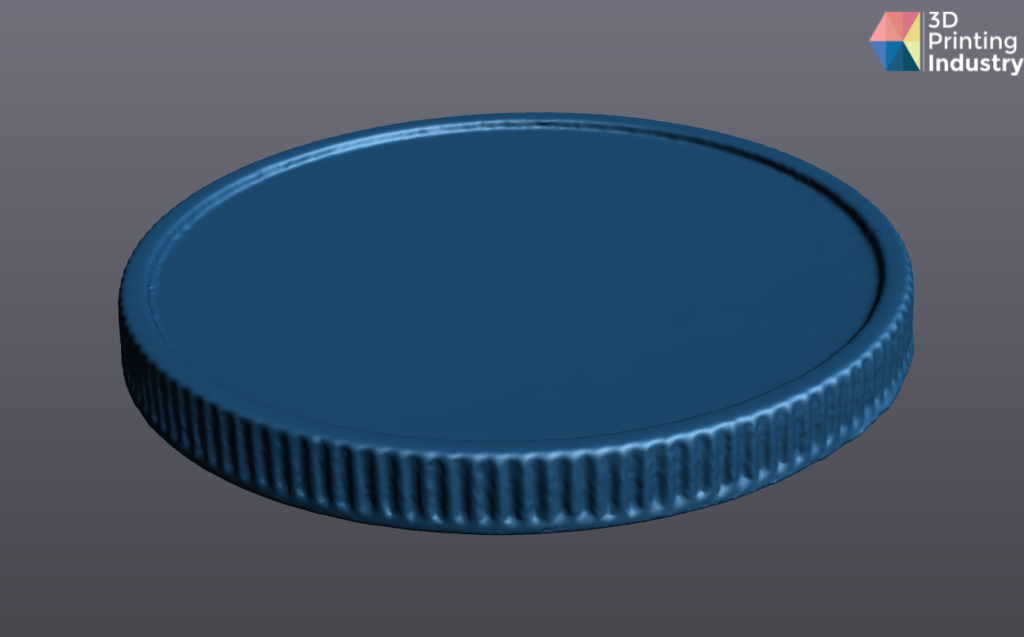

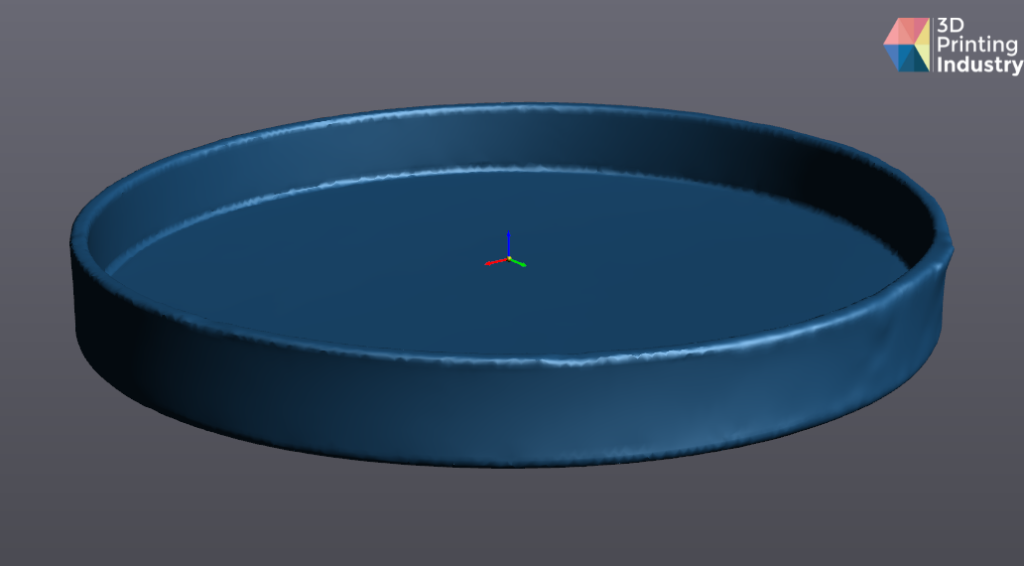

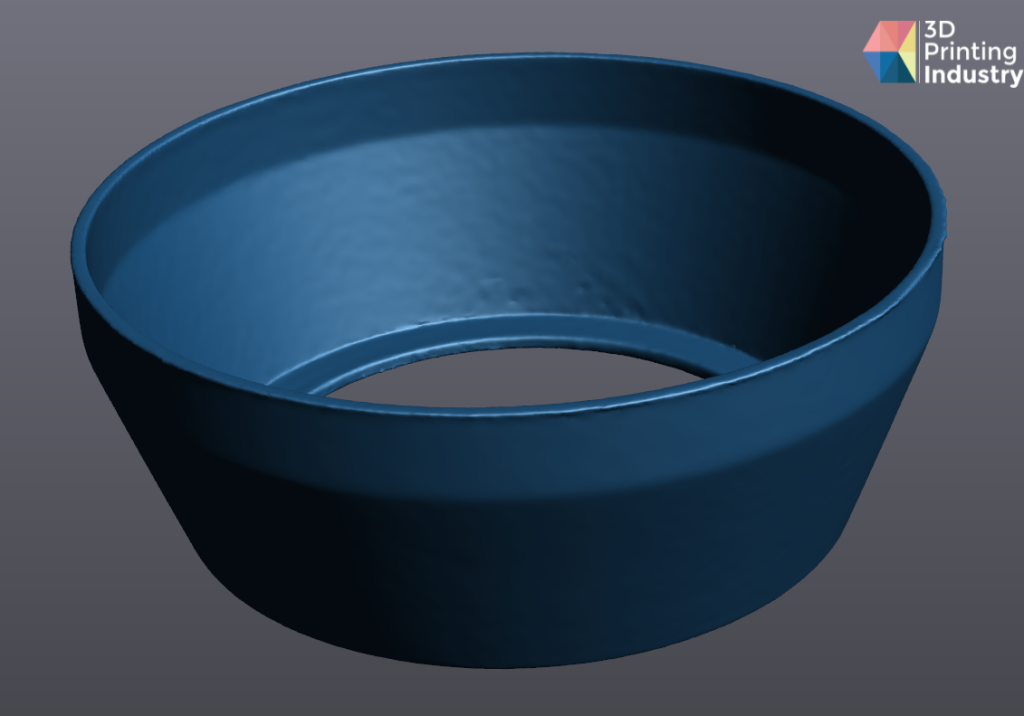

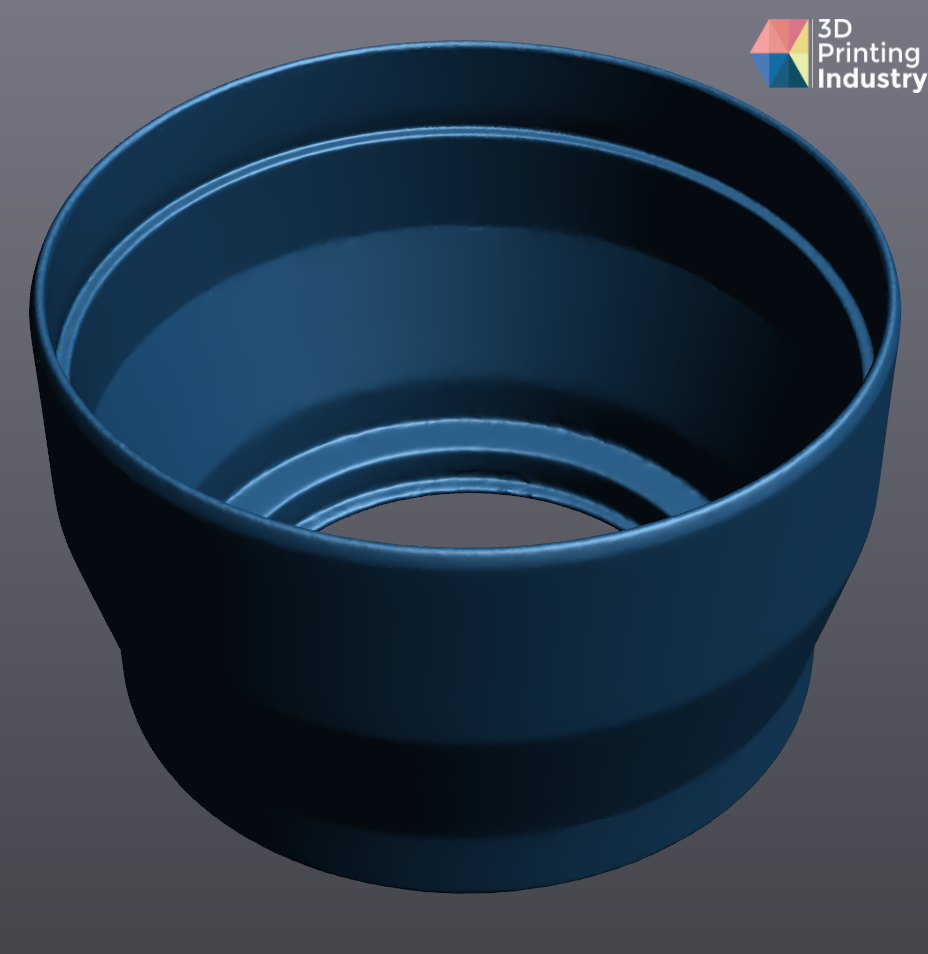

We next conducted 3D scans of four separate components of a disassembled camera lens. Some of the parts feature minuscule threads that enable the parts to screw together. Unfortunately, the 3D scanner did not successfully capture these components, as their geometry was too small to register. As such, the final meshes did not accurately represent the parts in full.

Camera lens scan results and scanned object. Images and photo by 3D Printing Industry.

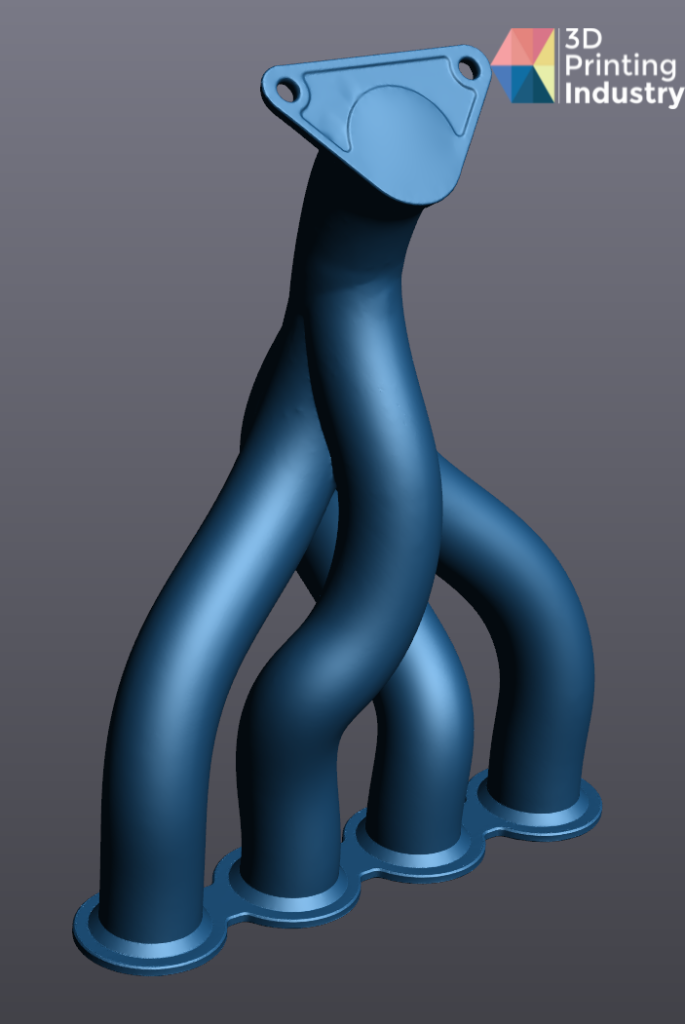

A large 3D printed inline 4 exhaust manifold was scanned next. This part was challenging due to its numerous angles and acute details. The results of this test were good, and highlight the ability of the 3D scanner to capture the complex shapes and overhangs of large engineering parts.

Exhaust manifold 3D scan results & scanned object. Image and photos by 3D Printing Industry.

To assess the value of the HandySCAN 3D|SILVER Series for applications within the fashion industry, we conducted a 3D scan of a Nike Dunk trainer. The results included impressive detail of the shoe’s leather surface and small threads. As such, we believe the 3D scanner could be further used for the production of keyrings or other collectible merchandise.

Finally, we assessed how well the 3D scanner is suited to measuring small components. The parts we measured were 3D printed capability pieces that we use in our 3D printer review testing process. In this test, the 3D scanner was used to successfully provide accurate measurements and clearly highlight the deviations of the 3D printed parts compared to the original file.

Capability test scanned objects and 3D scan results. Image and Photo via 3D Printing Industry.

Final verdict

Overall, the HandySCAN 700|Elite 3D scanner offers high-quality and accurate 3D performance, being well suited to engineering applications.

The product works well with the VXelements software suite, which is notable for its wide range of post-processing options that can enhance the original scans. Final meshes and models can be easily exported into other 3D software, making reverse engineering and 3D printing an easy process.

Beginners may struggle when first using the software, which offers a fairly steep learning curve. However, Creaform’s software team offers excellent after-sales support to help users overcome any challenges.

We encountered very few issues during our testing. The 3D scanner was found to be well suited to a wide range of surface materials and textures, due to its variable shutter speed and auto-adjust features. The accuracy of the HandySCAN 700|Elite was also very impressive, making it well-suited to both small and large objects.

Ultimately, the 3D scanner stands up to the claims made by Creaform and is well-positioned as a high-quality, metrology-grade option for professional users within the engineering space. This product is perfectly suited to those wishing to test the accuracy of 3D printed parts or conduct reverse engineering with no reference file.

Technical specifications table of the HandySCAN 700|Elite

| Accuracy | Up to 0.030 mm (0.0012 in) |

| Volumetric Accuracy (based on part size) | 0.020 mm + 0.060 mm/m (0.0008 in + 0.0007 in/ft) |

| Volumetric Accuracy with MaxSHOT Next Elite | 0.020 mm + 0.015 mm/m (0.0008 in + 0.00018 in/ft) |

| Measurement Resolution | 0.050 mm (0.0019 in) |

| Mesh Resolution | 0.200 mm (0.0078 in) |

| Measurement Rate | 480,000 measurements/s |

| Light Source | 7 blue laser crosses (+ 1 extra line) |

| Laser Class | 2M (eye-safe) |

| Scanning Area | 275 x 250 mm (10.8 x 9.8 in) |

| Stand-off Distance | 300 mm (11.8 in) |

| Depth of field | 250 mm (9.8 in) |

| Part Size Range (recommended) | 0.1–4 m (0.3–13 ft) |

| Software | VXelements |

| Output Formats | .dae, .fbx, .ma, .obj, .ply, .stl, .txt, .wrl, .x3d, .x3dz, .zpr, .3mf |

| Compatible Software | 3D Systems (Geomagic Solutions), InnovMetric Software (PolyWorks), Metrologic Group (Metrolog X4), New River Kinematics (Spatial Analyzer), Verisurf, Dassault Systèmes (CATIA V5, SOLIDWORKS), PTC (Creo), Siemens (NX, Solid Edge), Autodesk (Inventor, PowerINSPECT) |

| Weight | 0.85 kg (1.9 lb) |

| Dimensions (LxWxH) | 77 x 122 x 294 mm (3.0 x 4.8 x 11.6 in) |

| Connection Standard | 1 X USB 3.0 |

| Operating Temperature Range | 5-10°C |

| Operating Humidity Range | 10-90% |

| Certifications | EC Compliance (Electromagnetic Compatibility Directive, Low Voltage Directive), compatible with rechargeable batteries (when applicable), IP50, WEEE |

What is the future of 3D printing?

What near-term 3D printing trends have been highlighted by industry experts?

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows Creaform’s HandySCAN 700|Elite 3D scanner and its accessories. Photo by 3D Printing Industry.