Additive manufacturing data specialist Senvol has showcased how its machine learning (ML) technology can be used to accelerate the qualification of new aerospace 3D printing materials.

Working under a contract awarded by US 3D printing accelerator America Makes, the firm has deployed its Senvol ML software to rapidly and cost-effectively identify property allowables during material R&D. Funded by the US Air Force (USAF), it’s thought that the project’s findings could be key to producing a new generation of durable lightweight parts, with both aerospace and commercial applications.

“I have been involved with the qualification of several additive manufacturing processes and materials for flight,” said Dr. William E. Frazier, retired Chief Scientist at NAVAIR and project participant, “and in my opinion, the further development of this technology will have a positive impact on the cost, schedule, and performance of both Department of Defense (DoD) and commercial platforms.”

“Senvol’s ML-enabled approach directly addresses a major industry challenge: the rapid and cost-effective development of additive manufacturing material property allowables.”

Senvol ML’s military potential

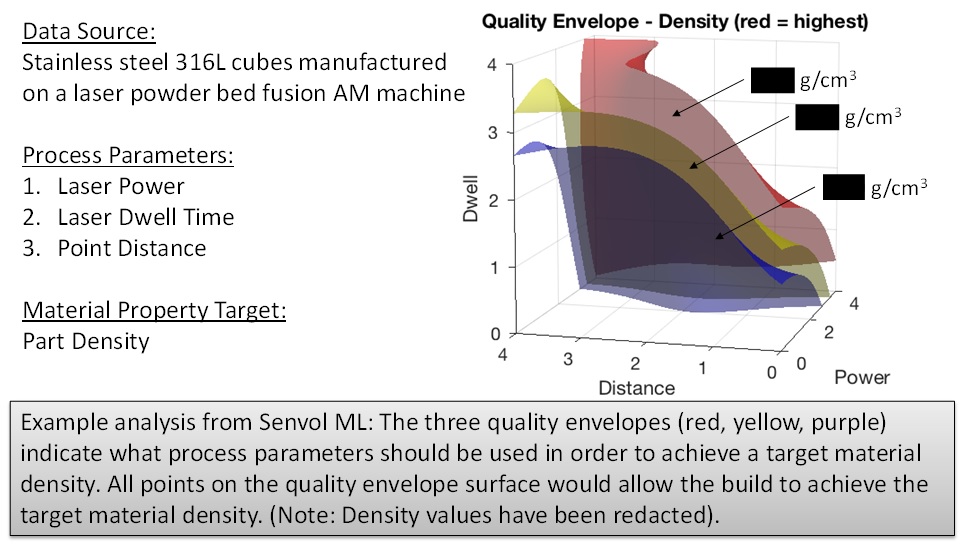

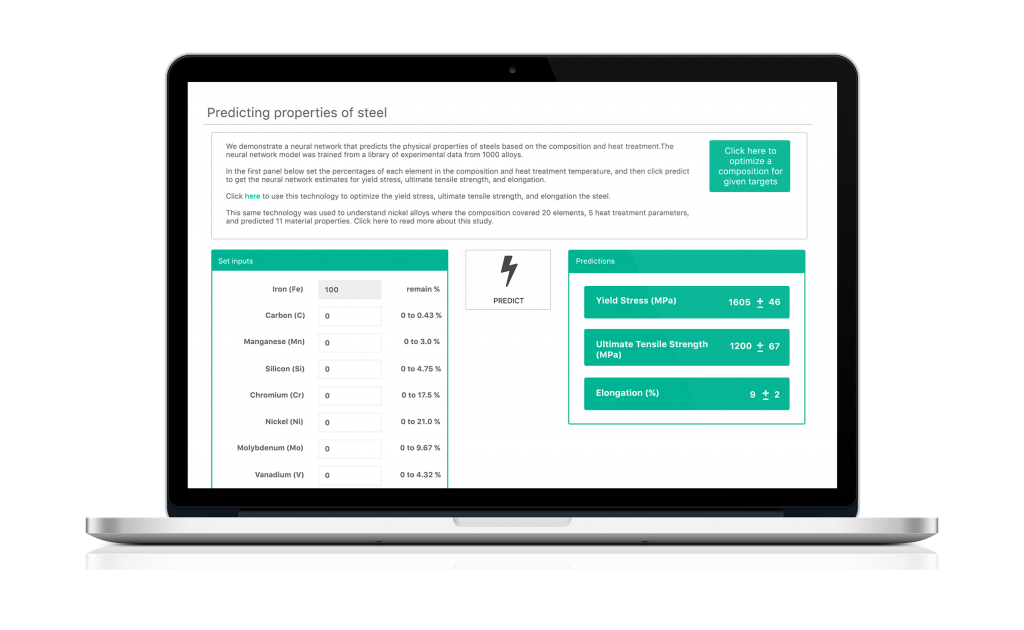

In effect, Senvol ML is a data-driven software that can be used to analyze the relationships between 3D printing parameters and the end-performance of a material. Not tied down to any one technology, the program, which is compatible with all known AM processes, enables users to generate a set of parameters for their system or material, based on a pre-set target mechanical performance.

Senvol ML largely owes its powers of prediction to its modularized integrated computational materials engineering or ‘ICME’ framework. Split into four modules, this ICME quantifies the relationship between data gathered on parameters, material properties, process signatures and mechanical performance, to generate predictions of how any resulting parts will behave at a rapid rate of knots.

In doing so, Senvol ML provides a vital quality assurance tool to adopters in the aerospace, defense, consumer, medical, automotive and oil & gas sectors, and the technology is now increasingly finding military applications too. Since 2020 alone, Senvol has used its software to aid the printing of large-format aero-parts and develop a missile qualification workflow, while gaining DoD funding for further R&D.

“Senvol’s data-driven machine learning technology has the potential to substantially reduce the cost of material allowables development,” says Senvol President Zach Simkin. “By demonstrating an entirely new – and significantly more efficient – approach to allowables development, Senvol aims to drive tremendous value for the US Air Force, the America Makes membership, and the additive manufacturing industry at large.”

Material qualification at pace

Senvol’s America Makes research project was centered around the process of identifying a material’s ‘property allowables.’ Also known as ‘design allowables,’ these values essentially represent a statistically-determined minimum durability property that materials need to have, in order to make them viable within particularly demanding applications.

Specifically, the program tasked the firm with showcasing how the machine learning algorithms of its Senvol ML software can be used as a means of accelerating this process, while driving down the vast amount of empirical data normally required to do so, something that can be a roadblock to 3D printing’s wider military deployment.

“Additive manufacturing is a modern and digital manufacturing method with rapidly tailorable processing,” explains Dr. Brandon Ribic, Technology Director of America Makes. “To continue to use traditional material allowables development approaches, is a bottleneck to wider material and process options and capabilities for additive manufacturing.”

According to Ribic, Senvol managed to overcome this bottleneck by developing a data analysis-driven approach to qualification, which exhibited the capabilities of its software in a “very powerful” way. In fact, working with Northrop Grumman, the National Institute for Aviation Research (NIAR), Stratasys Direct Manufacturing and Pilgrim Consulting, it’s said that the firm was able to identify substantiated material properties, while simultaneously optimizing its data generation requirements.

Although the program saw Senvol focus its efforts on finding the property allowables for a flame retardant Nylon 11 processed via a powder bed fusion machine, it says that its approach can be applied to “any AM process, machine and material,” to qualify their parameters more quickly, affordably and accurately than traditional methods allow.

“The results of this America Makes program were incredibly successful,” concluded Simkin. “Additionally, we identified several other opportunity areas to go deeper into the machine learning capabilities to address this critical need for the industry. We look forward to continuing to partner with industry to advance this cutting edge area.”

A fresh approach to qualification?

Compared to conventional ‘trial and error’ approaches to material qualification, machine learning-based algorithms offer a means of eliminating the human mistakes behind failed prints. Though many such programs remain at an experimental level, the benefits of software developed by the likes of Senvol ML and Intellegens, are now beginning to make it onto the factory floor.

Just last year, the latter worked with the University of Sheffield’s AMRC and Boeing, to come up with an newly-optimized approach to 3D printing aerospace parts. Utilizing the firm’s own Alchemite ML platform, the project was set up with the goal of enhancing the powder bed fusion process, in a way that ensured components could be produced faster, cheaper and from more materials than before.

Similarly, engineers at the Massachusetts Institute of Technology (MIT) have developed an open-source ML algorithm that’s designed to help a wider audience expedite the process of identifying 3D printable materials. Packaged within their ‘AutoOED’ software, the team’s program is capable of automatically identifying viable materials with desired qualities such as toughness, rigidity and strength.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper-dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, de-briefs and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a fleet of US Air Force aircraft. Photo via Mikayla Heineck, US Air Force.