nScrypt, a Florida-based manufacturer of micro-dispensing and 3D printing equipment, has delivered its SmartPump tool head to an undisclosed electronics manufacturer for use on its factory floor.

This micro-dispensing tool enables multi-material 3D printing, allowing fabrication of smart and microfluidic devices.

Micro-dispensing technology

Since its founding in 2002, nScrypt has focused on additive manufacturing and micro-dispensing. Micro-dispensing involves depositing droplets of ink in volumes of less than one microliter. This process facilitates multi-material 3D printing, which has been incorporated in nScrypt’s hybrid gantry system. Micro-dispensing also allows the fabrication of smart devices, conformal antennas, and microfluidic devices.

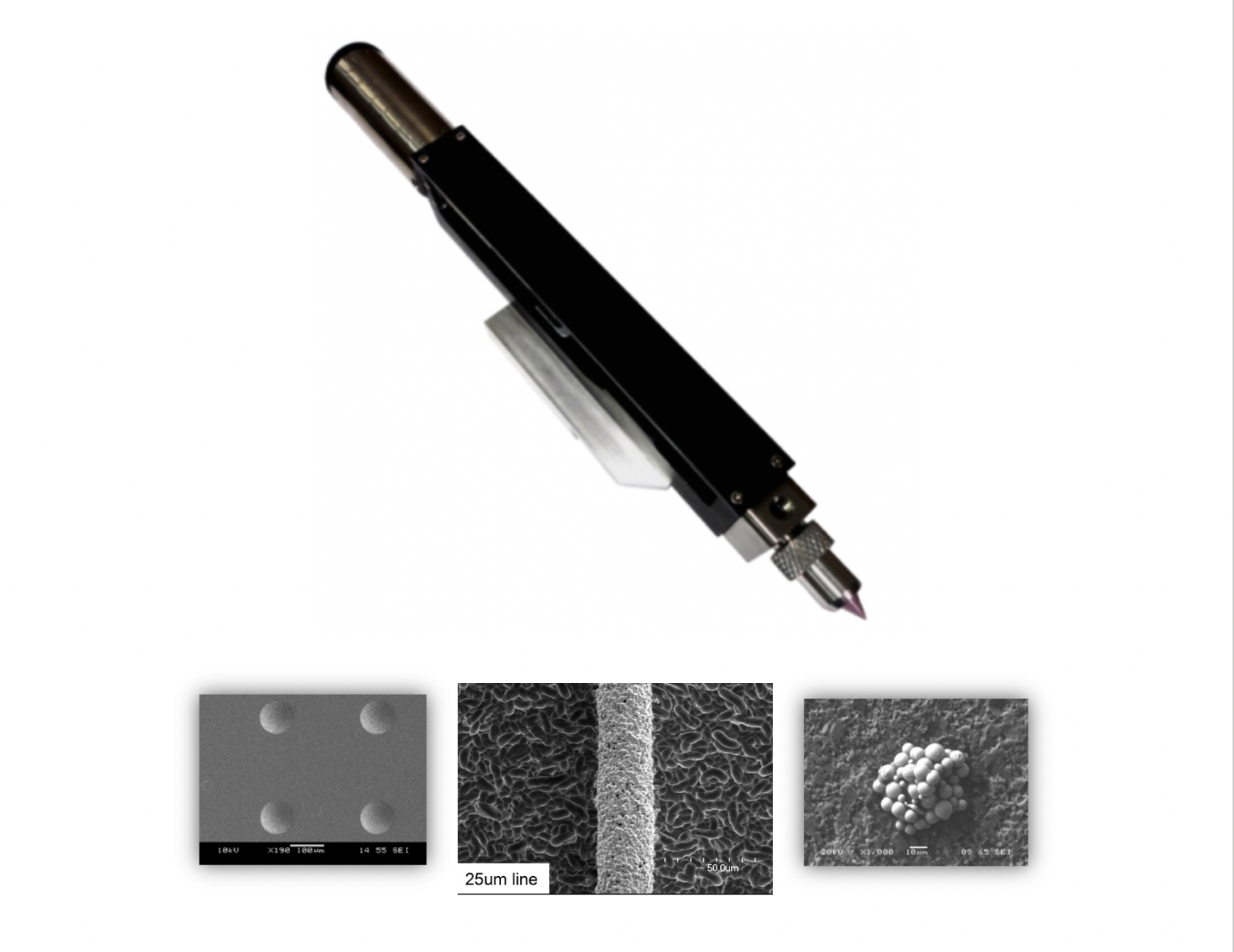

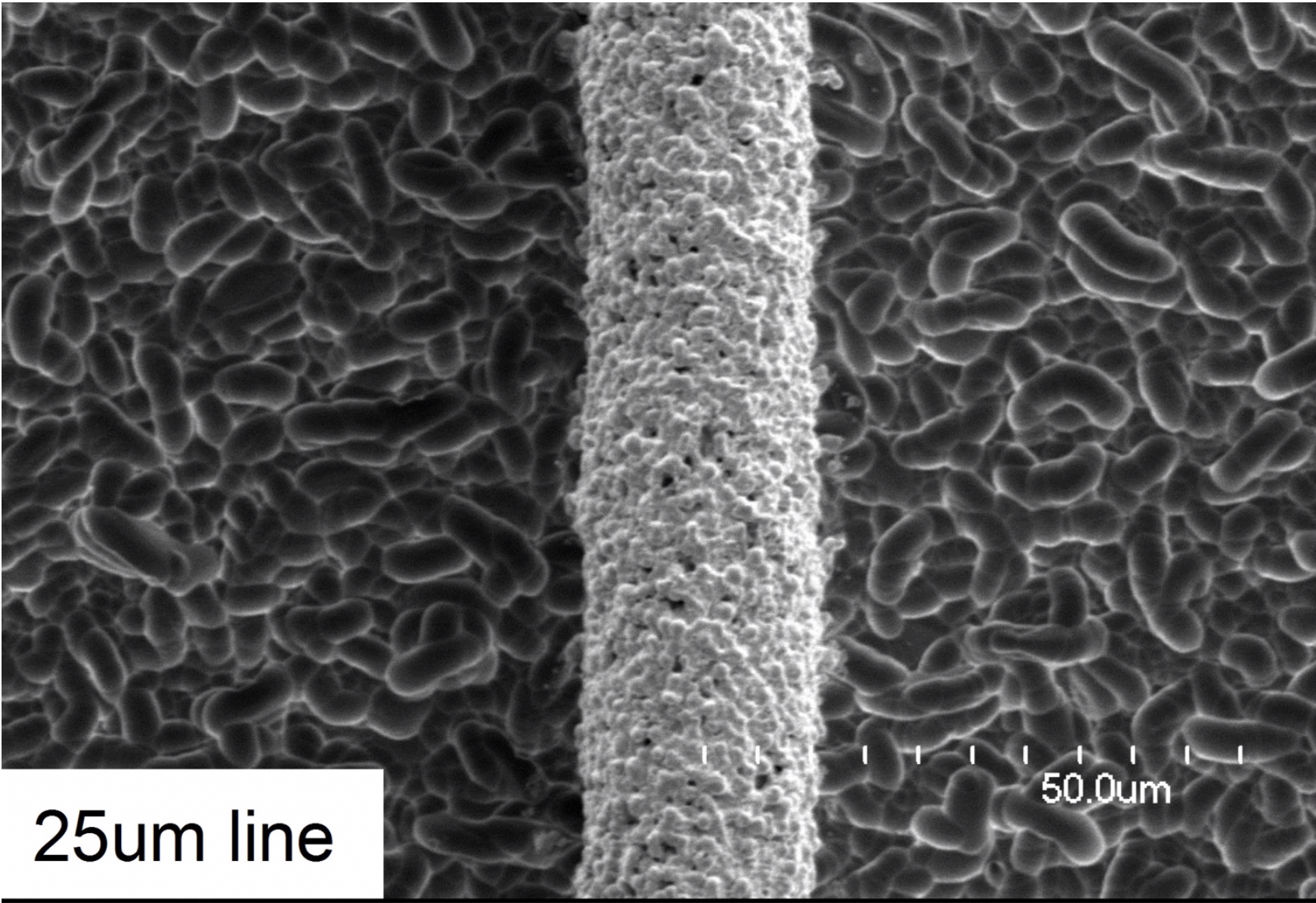

The SmartPump is a proven, rugged micro-dispensing pump with leading material range, volume control and dimensional size of prints. Last year, a patent was awarded to the company for a new high-speed micro additive manufacturing method that enables a wider material palette or technology capable of 3D printing onto a range of shaped surfaces. It can dispense more than 10,000 commercially available materials with volume control up to 20 picoliters.

While the smallest competitive pen tips are 100 microns, the SmartPump nTip achieved the smallest commercially available diameter of 10 microns. Drooling is eliminated with pico-liter volumetric control in the system, enabling near-perfect starts and stops of materials. Furthermore, it allows printing of mateirals with extreme viscosities, ranging from 1cP nanoparticle inks to well over 1 million cP flake-loaded pastes.

Application in electronics manufacturing

This micro-dispensing tool is often sold as part of nScrypt’s digital manufacturing platforms such as Factory in a Tool, 3Dn, DDM, BAT, and SVA Series machines. nScrypt made an exception for the electronics manufacturer as it has purchased a large number of the product.

“This customer has used our SmartPump for years, but recently started using it on the factory floor. This use of our SmartPump as a production line workhorse to print micron-level adhesive dots validates our battle-hardened micro-dispensing technology,” said Dr Ken Church, CEO of nScrypt.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also keep connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows nScrypt’s SmartPump and print results. Imgae via nScrypt.