U.S Navy and Army bring 3D printing technology on board to speed up operations. Over a 28 month period, the Navy’s USS George HW Bush (CVN 77) aircraft carrier will be upgraded with conventional and 3D printed parts.

Jeff Burchett, project superintendent of USS George HW Bush, said, “There are a lot of first-time jobs all around, given this is the first time Bush has sat on keel blocks since being built. With the size of this work package, it will take a total team effort by NNSY.”

The scheduled overhauling of the $6.2 billion aircraft carrier will take place at the Norfolk Naval Shipyard (NNSY).

In addition to this, the U.S. Marines and the Army are integrating 3D printing on a wider scale for various applications.

Marine Corps. 3D

In recent years, the U.S. Department of Defense (DoD) has taken measures to incorporate advanced manufacturing techniques into the military and air force operations. This also includes the rapid adoption of additive manufacturing.

Every day, 3D printing is becoming an essential part of the U.S. military.

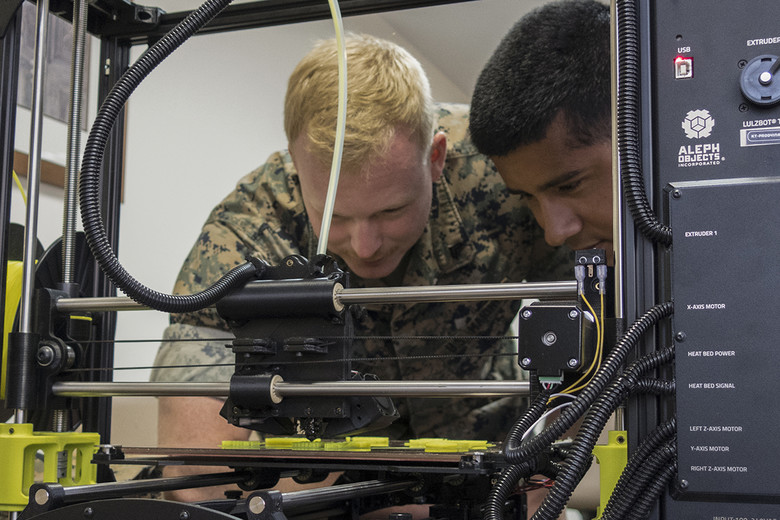

At the Marine Corps Air Ground Combat Center in Twentynine Palms, the 2nd Battalion, 7th Marine Regiment is the first unit to deploy a 3D printer in their unit.

1st Lt. Ryan McCormic, motor transport officer for 2nd Battalion, 7th Marine Regiment, said, “One of my plans is that we take our 3D printer with us on [deployment] and utilize it in country when somebody tells us that we have a dead vehicle or a [faulty] weapon.”

“We bring this 3D printer and instead of possibly having a 2-3 week wait time for the part, we can print it right there.”

Furthermore, the Marine Corps Systems Command (MCSC) has also set up an Advanced Manufacturing Operations Cell which provides round-the-clock help for Marines using 3D printing technologies.

Capt. Matthew Friedell, AMOC project officer, said, “The AMOC is manned 24/7 to help Marines talk through their problems and find solutions quickly […] With the current state of manufacturing technology and digital manufacturing across the world, there’s no reason Marines shouldn’t be well educated on it and have access to it any time of day.”

Friedell explained further the purpose of AMOC. He said, “The Advanced Manufacturing Operations Cell is a team of Marines and civilians centered on helping fleet Marines find parts they need to keep their equipment functioning efficiently.”

“Our motto is, ‘If we can’t find it, we’ll make it.’”

Simon says 3D print it

As was previously reported the U.S. Air Force is using the FiT manufacturing system of Florida-based nScrypt, to manufacture phased array antennas.

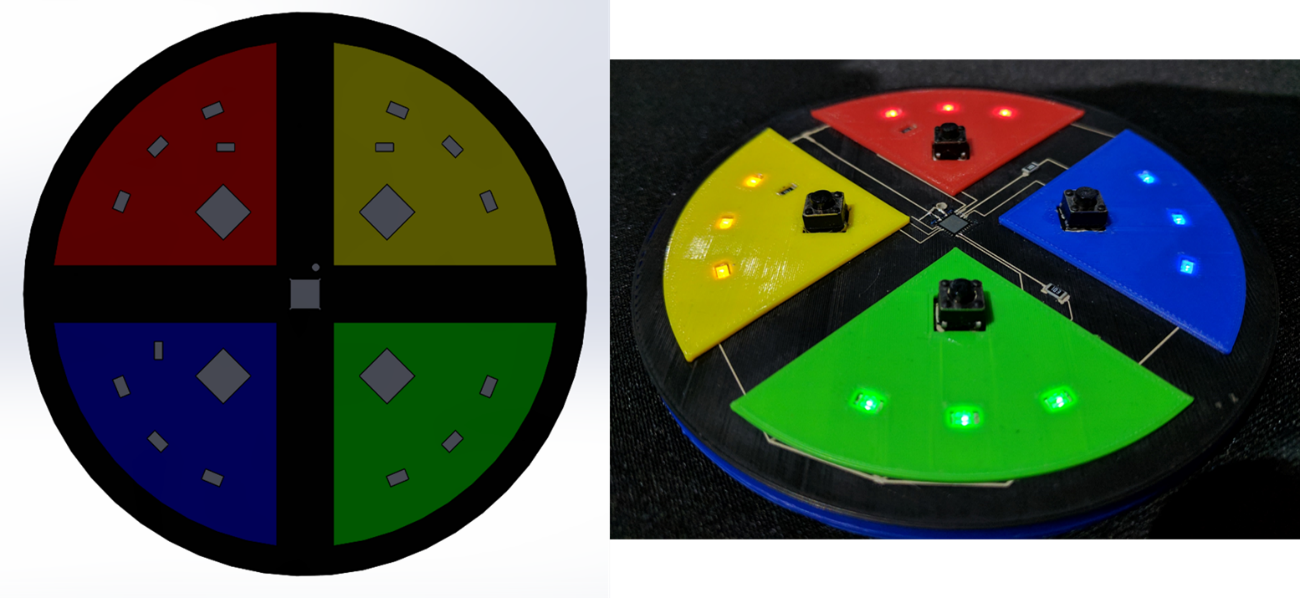

Now, in a recent collaboration between nScrypt and various branches of the U.S. Army have manufactured a 3D printed version of the popular memory skill game Simon. This demonstrated the capabilities of the nScrypt FiT system and its potential to 3D print electronics.

Ken Church CEO of nScrypt explained, “Direct Digital Manufacturing is going from a CAD file to a final, multi-material electronic product, like the Simon Says, in a single machine, without retooling. People love to play with the Simon Says, which we bring to our trade show booths, and they are amazed that it was made in a single build.”

The making of Simon was a joint effort among the New Jersey-based U.S. Army Armament Research, Development and Engineering Center (ARDEC), the Army Research Laboratories in Maryland, and nScrypt.

The manufacturing process and its findings were published in a paper titled “Direct Digital Manufacturing For 3D Electronic Packaging.” It was jointly authored by James Zunino of ARDEC, Jaret Riddick of ARL, nScrypt CEO Ken Church, and three engineers at nScrypt, Sam Leblanc, Casey Perkowski, and Dasan Costandi,

The Simon 3D printed circuit was made with ABS and PLA and built using extrusion and milling process in a single step in the FiT system.

The authors of the paper explained the future potential of 3D printing electronics, “Antennas can be printed on or within a structure, RF shielding can be printed in strategic locations of the electronic package, sensors can be printed and permeate throughout the structure, and all of these can be done using much less space and volume.”

“Devices can be printed within devices or 3D shapes by changing materials, which eliminates the need for solder, nuts, bolts, and excess bulk wires.”

Nominations for 2019 3D Printing Awards are closing tomorrow. This is your last chance to make nominations!

For more news on the latest developments in additive manufacturing, subscribe to our 3D printing newsletter and join us on Facebook and Twitter.

We have some great jobs in the industry, visit our 3D Printing Jobs page to learn more.

Featured image shows a helicopter landing on the USS George HW Bush (CVN 77) aircraft carrier in the Atlantic Ocean. Photo via Micah P. Blechner/U.S. Navy.