The U.S. Air Force (USAF) has awarded Sciperio, a Florida-based research group, Phase II funding to develop 3D printed phased array antennas.

Established in 1996, Sciperio is an R&D company specializing in various fields such as bioengineering and wireless communication devices.

For the latest project, Sciperio will use the Factory in a Tool (FiT) system to manufacture custom-shaped antennas for UAVs and aircraft. The FiT platform was developed by Sciperio for its Florida-based spin-off nScrypt.

Phased array

Radars communicate with each other through electromagnetic waves. Such waves are uniform in size with a circular pattern and travel in all directions. As the pattern is wide and uncontrolled, it could easily lead to communication interference, as other devices in the vicinity may also be producing electromagnetic waves.

In contrast to the circular wave pattern is the phased array antenna. This sends signals using a narrow and focused beam of electromagnetic waves. For military and air force applications phased array antennas are more reliable for secure communication.

However, generally, it is the case that the bigger the antenna the narrower the beam is. But large-sized antennas come with their own problems such as the increase in size and weight of a vehicle or aircraft they are mounted onto.

The FiT system

nScrypt’s FiT system which the U.S. Army has utilized in the past, has shown the ability to counter the problem of large unwieldy radar antennas. The FiT system is a multiple tool head manufacturing machine which can extrude, dispense, and mill to manufacture electronics.

It is described as a machine that, “digitally fabricates anything from 2D and 3D printed circuit structures (PCS) to biological structures and can be used almost anywhere on the digital manufacturing floor.”

The FiT system can manufacture miniature phased array antenna on customized surfaces, which can then be mounted to a UAV or aircraft as part of its structure rather than a separate system.

U.S. Air For use of 3D printing

As has been frequently reported, the U.S. Air Force has utilized 3D printing technology effectively. USAF’s wider aim is to integrate the technology into its manufacturing operations. So far, among the benefits of the Air Force has reaped from the additive manufacturing are the reduction of lead times and costs.

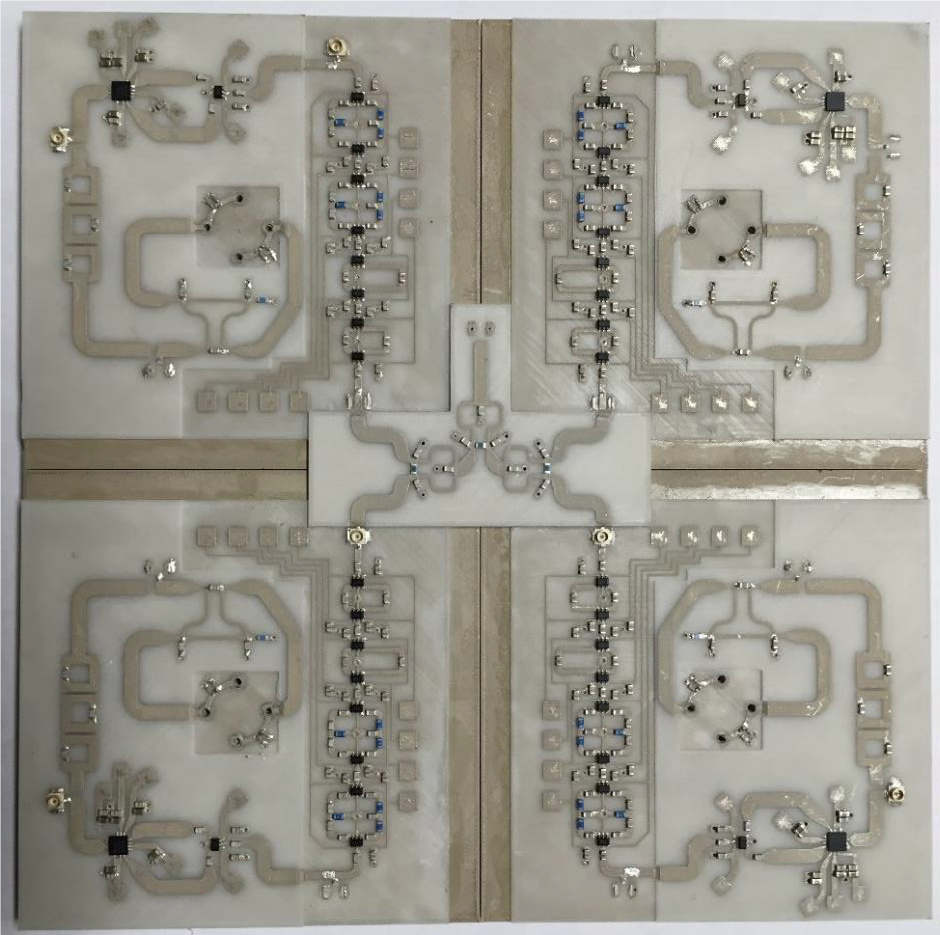

Now, with the help of nScrypt’s FiT system Sciperio will produce an 8 x 8 antenna array on an ellipsoid surface as a functional prototype for USAF.

Casey Perkowski, a mechanical engineer at Sciperio and lead developer on the project, explained “Directly printing active phased array antennas on curved surfaces will provide unique capabilities to the DoD (Department of Defense), but the ultimate goal is to do this at a fraction of the cost of traditionally manufactured arrays. This will allow the DoD to use these antennas in a more ubiquitous manner and this will translate to commercial applications.”

Furthermore, the University of South Florida will be a subcontractor which will oversee the design and testing of the phased array antennae.

Nominations for 3D Printing Awards 2019 are open now. Pick the best aerospace applications of 3D printing.

For more news on the uses of additive manufacturing, subscribe to our 3D printing newsletter. You can also join us on Facebook and Twitter.

If you are looking for a job in the industry then visit our 3D Printing Jobs page.

Featured image shows a small size phased array antenna. Image via nScrypt.