Progress moves fast in the 3D printing industry. So fast, in fact, that you can see a company go from just an idea, to a joint venture, to publicly trading shares, to launching its first product in just about two years. Even if that product is something as potentially game-changing as graphene-enanced conductive filament. That, in short, is the recent story of Graphene 3D Lab, a joint venture founded by Lomiko Metals and Graphene Laboratories. Its graphene filament is due to hit the market by the end of next month.

At 3DPI, we’ve followed every recent step of Graphene 3D Lab’s evolution, from its first patent registration, to its debut on the Canadian TSX and the development stage venture marketplace OTCQB. Now it is time for all that to come to its natural conclusion, with the announced large scale availability of graphene filaments as a new mature for low cost, desktop 3D printers. Graphene 3D Lab, which was officially established on February 12 2013, is thus moving from R&D to revenue making in record time.

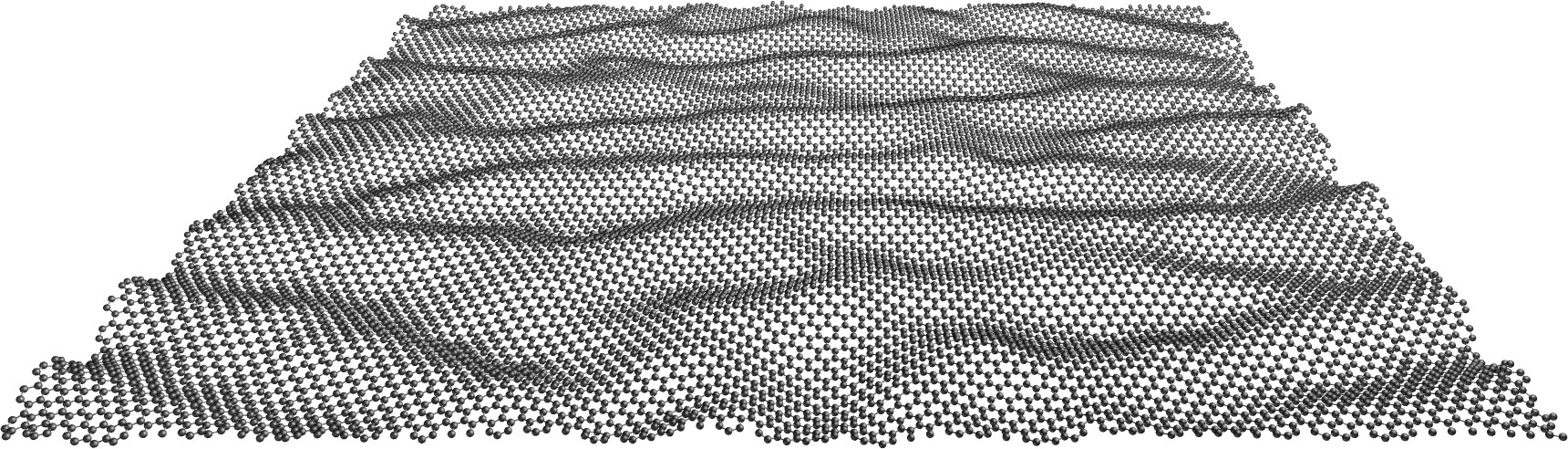

Demand for conductive filament is strong and, while different initiatives have implemented a more traditionalapproach, Graphene is considered a “the wonder material of our times” for its impact resistance, strength (it is 200 times stronger than steel), elasticity and conductivity properties (30 times faster than silicon). Like graphite, it is entirely composed of carbon atoms, which form repetitive hexagonal honeycomb formations. That – if anything – a big metaphorical hint as to its compatibility with 3D printing since the 2 dimensional hexagon can also be seen as the outline of a three dimensional cube, and is thus used in many 3D company’s logos.

To make graphene production affordable enough, Lomiko Metals and Graphene Labs convert graphite flakes into graphene oxide by oxidizing them. The method described on the original patent application focused on the possibility to use polymers infused with graphene, together with conventional polymers, in the same printing process, thereby enabling the fabrication of functional electronic devices, such as the batteries in this video and tons of possible future applications.