Articles surrounding a Liquid Additive Manufacturing (LAM) system and research around 3D printed liquid magnets were some of the most popular stories of the month.

A number of 3D printing firms also provided major updates, whether it was a new system, updated software or fresh brand image.

Liquid additive manufacturing

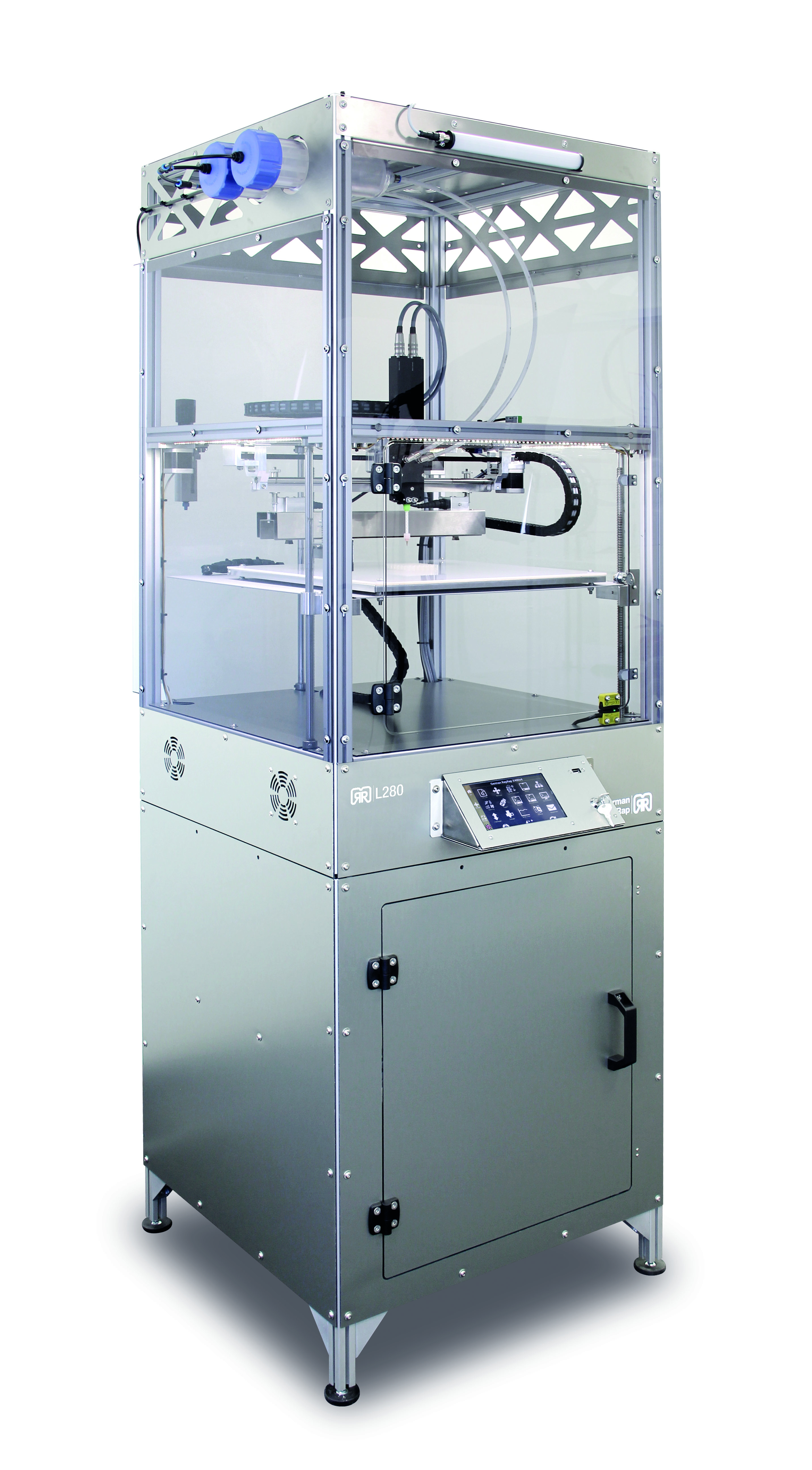

3D printer manufacturer German RepRap launched a new LAM system in July, named the L320. The system has a larger build volume than the L280, German RepRap’s first LAM printer, and can be used to process 3D printing liquid silicone rubber.

Additionally, a team of scientists from the Lawrence Berkeley National Laboratory used a modified 3D printer to produce liquid droplets imbued with magnetic properties. The research has the potential to enable 3D printed devices in a variety of useful and groundbreaking applications due to the combined liquid and magnetic qualities. This could include artificial cells that can deliver targeted cancer therapies or flexible liquid robots that can change their shape to adapt to their surroundings.

Other popular articles from July revolved around updates from big players in the 3D printing industry. A partnership between Carbon and Covestro, a German manufacturer of high-performance polymers, was announced to enable the mass production of Carbon’s polyurethane liquid resin.

Meanwhile at Stratasys, the company geared up to make a big announcement after reporting double-digit stock growth for Q2 2019. And Dutch 3D printer manufacturer Ultimaker announced a rebrand with a focus on professional 3D printing. Alongside the rebrand, the company also relocated its headquarters from Geldermalsen to Utrecht.

Developing a $15 million metal 3D printer

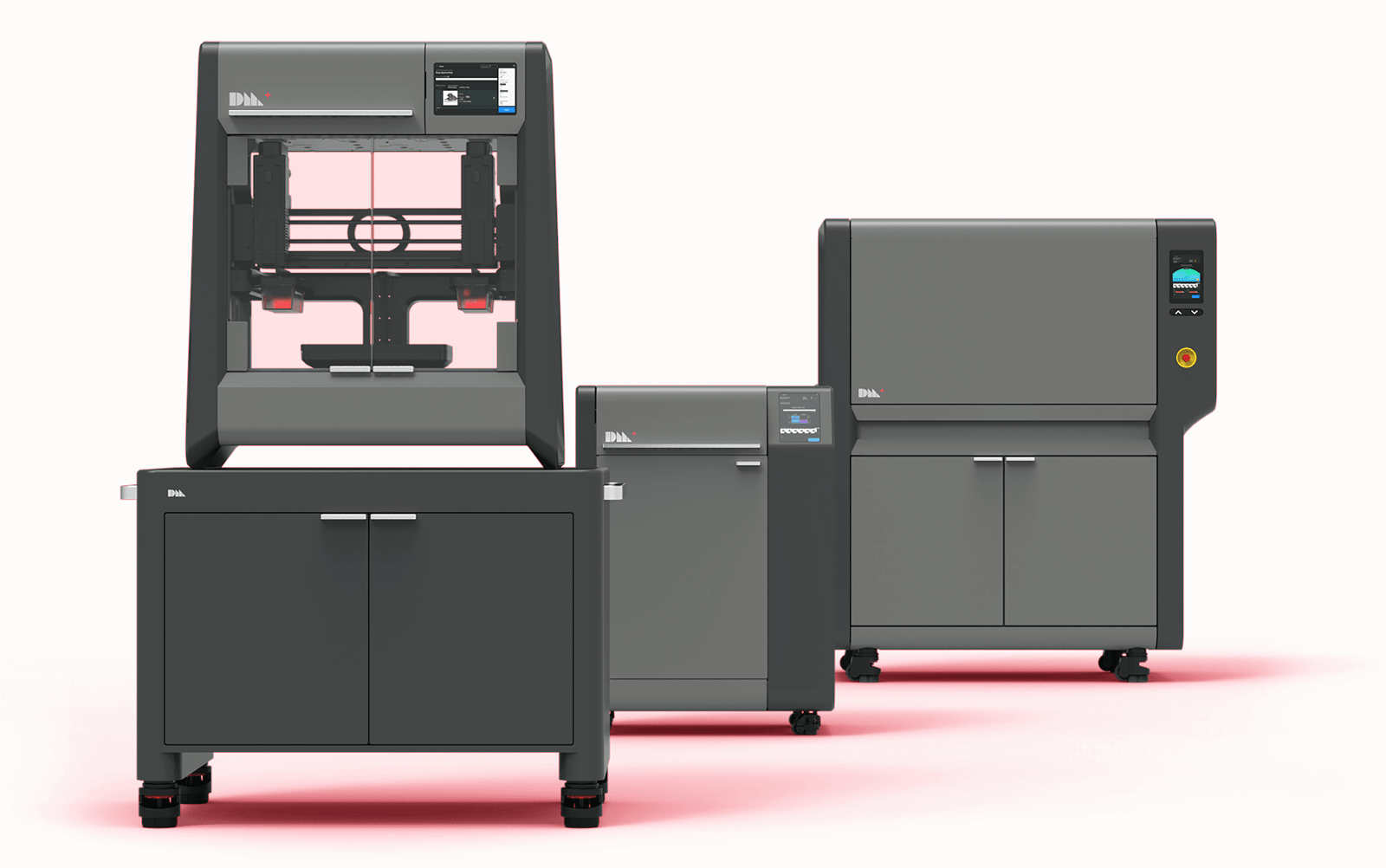

In metal 3D printing, Ford Motors demonstrated how it was planning to use 3D printing from Desktop Metal to drive its automotive production. After leading a $65 million investment round for Desktop Metal, Ford installed the company’s Studio System and Production System in its Research and Advanced Engineering Organization in Michigan.

Elsewhere in metal additive manufacturing, the Combat Capabilities Development Command of the U.S. Army Research Laboratory (ARL) awarded 3D Systems a $15 million machine development contract. Working with the National Center for Manufacturing Sciences (NCMS), 3D Systems was tasked with creating “the world’s largest, fastest, most precise metal 3D printer.”

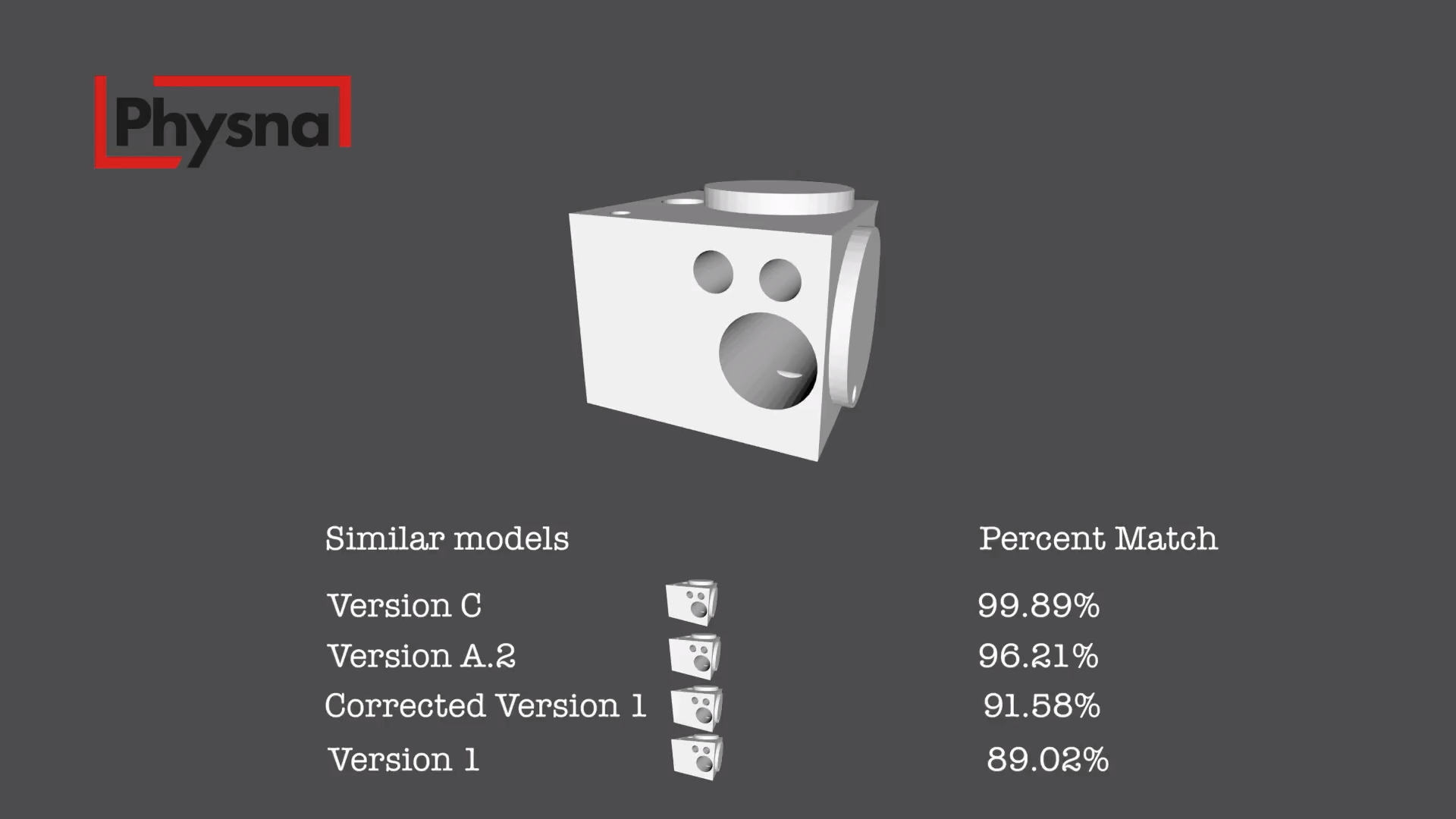

Moving on, there were also significant developments for 3D software in July. Physna, a Cincinnati-based 3D modeling software startup, announced the completion of a $6.9 million series A funding round. Physna planned to use the investment to further the development of its 3D model search engine, which allows users to compare and analyze thousands of 3D models for the purpose of quality control and automated inspection.

German 3D printing software developer 3YOURMIND was also awarded €1.3 million to integrate machine learning solutions into its additive manufacturing workflow. Finally, Global science-based company and material producer DSM launched its I AM Tomorrow Challenge for 3D software startups focused on data analytics, AI and other advanced software solutions. Streamlining the 3D printing process flow is highlighted as a goal of the challenge.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Spinning liquid magnet causes dye to swirl. GIF via Science Magazine.