Bostonian 3D printer manufacturer Desktop Metal has begun shipments of its Studio System in Europe. Marketed as the world’s first office-friendly metal 3D printing system for functional prototyping and low volume production, the Studio System is set to be installed by customers including Germany’s BMW Group, Politecnico Di Milano and Add+It in Italy, and Scottish engineering company Weir Group.

“When Desktop Metal first launched, we set forth a mission to fundamentally change how the world designs and produces metal additively manufactured parts, from functional prototyping to mass manufacturing,” said Ric Fulop, CEO and co-founder of Desktop Metal.

“We have been delivering on that vision throughout the U.S. and Canada, and are now ready to step onto the global stage to further accelerate our business expansion and answer the impressive demand of the European market.”

The Studio System in Europe

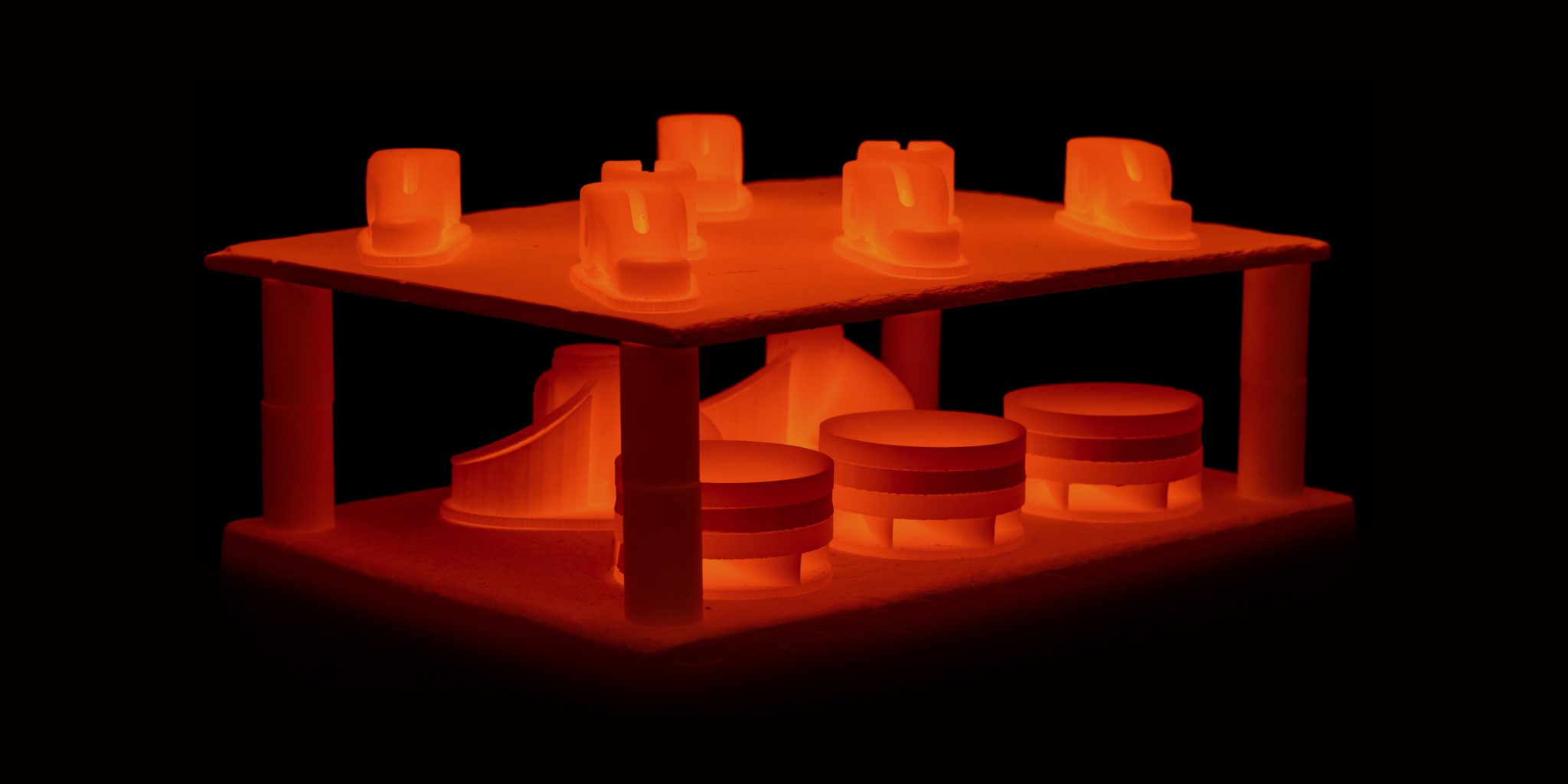

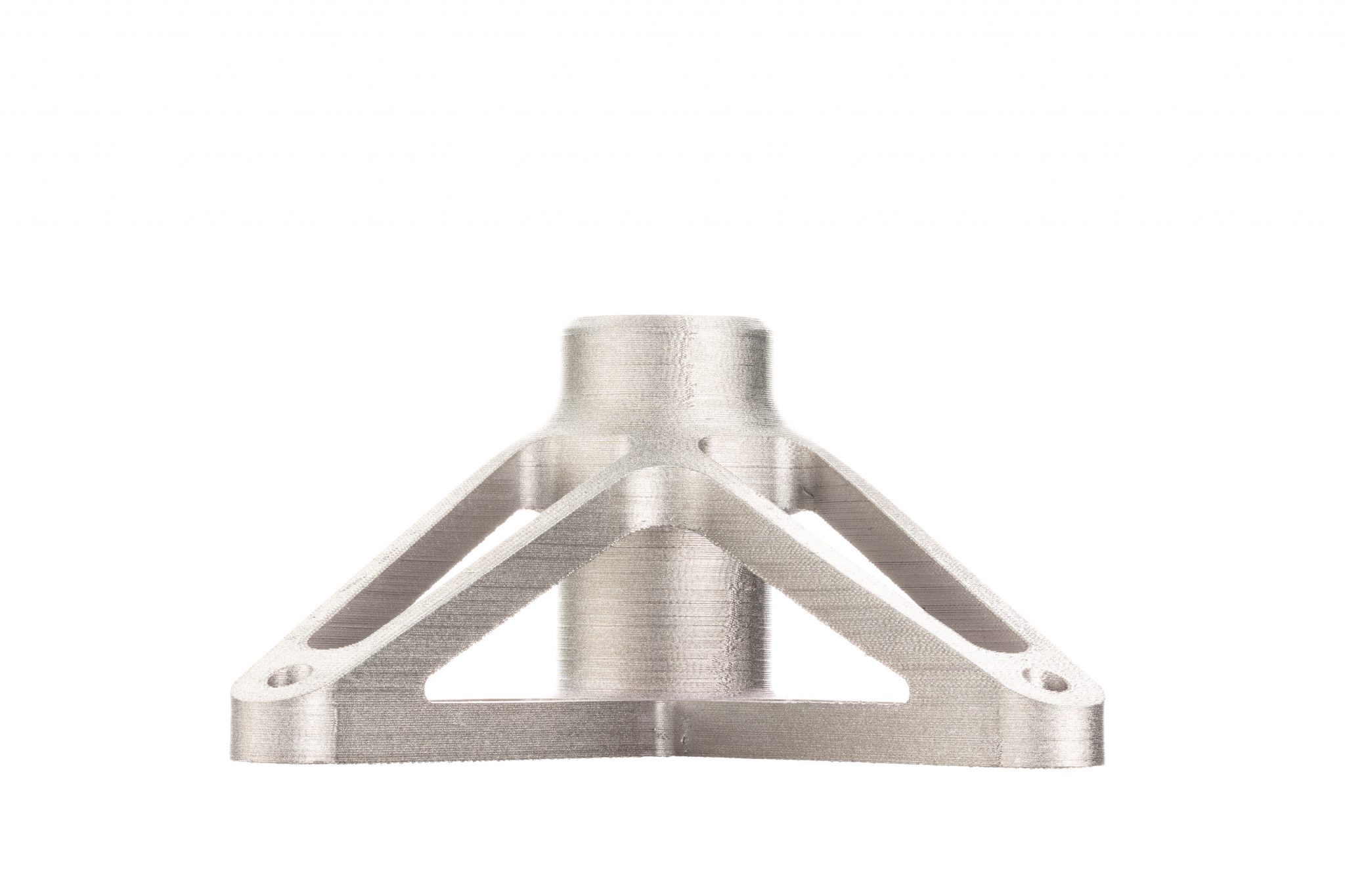

The Studio System, announced in April 2017, is Desktop Metal’s first 3D printing hardware which also includes a debinding station and furnace. The additive manufacturing technology integrated within the Studio System is FFF/FDM-based and uses a filament containing bound metal rods to create a part which is then sintered into a dense metal component.

Following intial U.S. shipments later that same year, Google’s Advanced Technology and Products (ATAP) group became one of the first customers to receive the Studio System. Presently, Studio Systems around the world have fabricated over 10,000 parts, including jigs & fixtures, zipper molds inserts, extrusion dies, as well as gear and motor mounts.

Accelerating metal additive manufacturing

Adding to the European adopters of the Studio System are polytechnic institute EGIBIDE and Centro Avanzado de Fabricación (IMH) in Spain, Industrial equipment suppliers Edalis, Soprofame and MSA in France, metal polishing company Jade Groupe in Portugal, BAZIGOS a mold manufacturer in Greece, and the city of Sheffield in the UK.

Jean-Baptiste Frenel, Director at Studio System customer Soprofame, commented “We decided to invest in the Desktop Metal Studio System in order to provide our customers a complementary solution to our machining expertise,”

“This innovative technology will allow us to answer our customer needs with more effectivity and reactivity.”

Nicolas Blanchard, Managing Director at fellow Studio System customer Edalis, added “Our design office and workshops allow us to deliver final end-use parts. Our choice to invest in the Desktop Metal Studio System is based on our willingness to continue innovating for our customers, complement our quality equipment installed base and be very agile thanks to the easiness and flexibility of this tool.”

Currently, the Studio System is shipping in the U.S., Canada and Europe, and is also available to reserve in 48 countries, including Asia Pacific, EMEA, and Mexico. European customers will receive their Studio Systems in less than eight weeks.

Want the latest additive manufacturing news? Subscribe to the 3D Printing Industry newsletter and follow us on Twitter and Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Desktop Metal Studio System including metal 3D printer, debinding station and furnace. Image via Desktop Metal.