The 3D Printing Industry news digest offers a summary of the latest partnerships, award presentations, software updates, material releases and applications from across the sector. In this update, we have snippets featuring Dr. Hans Langer, Mimaki, Velo3D, Dassault Systèmes, bionics hands, 3D printed lampshades, automotive repair and more.

Dr. Hans Langer achieves esteemed AMUG recognition

3D Printing Industry Outstanding Contribution award winner Dr. Hans Langer has been selected for the AMUG Innovators Award. Presented by the Additive Manufacturing Users Group (AMUG) to those who have advanced the additive manufacturing sector, Dr. Langer has been awarded for his efforts as the founder of EOS GmbH, and current Chairman and CEO of the EOS Group.

“Hans’ journey in additive manufacturing is an interesting tale that begins with him capitalizing on an opportunity created by the possibilities that others’ had rejected,” commented AMUG President Carl Dekker.

“With his background and lengthy list of achievements, he is an excellent addition to the exemplary list of recipients of the Innovators Award.”

The award will be presented to Dr. Langer at the 2020 AMUG Conference following a presentation during the Innovators Showcase.

Mimaki integrates Cuttlefish control

Metal 3D printer provider Velo3D has commenced expansion in Japan signing a distribution agreement with Taiyo Nippon Sanso Corporation (TNSC). A global provider of welding solutions and industrial gases, TNSC is now licensed to resell the Sapphire machine as well as Flow and Assure software in the region.

In another strategic agreement, Boston-based 3D printer manufacturer RIZE has announced it will be partnering with Dassault Systèmes. The partnership will see RIZE integrate its 3D printing technology with 3DEXPERIENCE software for customers in North America.

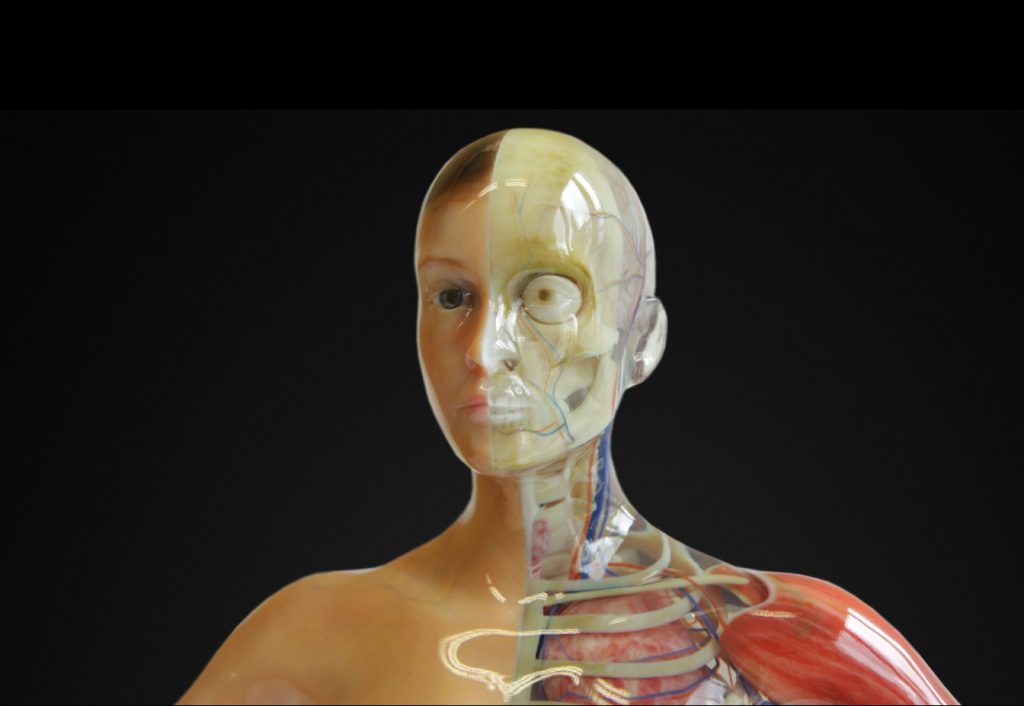

Cuttlefish, a universal 3D printer driver developed at the Fraunhofer Institute for Computer Graphics Research IGD, has been integrated by full color 3D printer provider Mimaki. With this software, users of the Mimaki 3DUJ-553 will have further control over the geometry, colors and material transitions of their models.

Specialist ceramic component manufacturer DOCERAM has published a 3D CAD portal of welding components. Available to download for free, the files can be used to integrate CAD data into design and simulation processes.

And Senvol, the most comprehensive 3D printing database has been integrated into the Additive Manufacturing Knowledge Area of KEX Knowledge Exchange AG. Commenting on the new utility Patrick Wienert, Partner at KEX Knowledge Exchange, commented, “KEX.net empowers its users to connect the AM machine and material data from the Senvol Database to real application examples and exclusive research knowledge. The platform actively engages its users to generate innovative application ideas and at the same time indicates possible partners, technologies and materials for a fast implementation.”

Swiburne’s car-fixing robot proves itself with headlight application

Low energy lighting designer Plumen has launched a collaboration with UK based service bureau Batch.works. Together the companies have created a range of light shades made from recycled plastic. Amsterdam social enterprise Reflow, provided the source material. “We believe that thinking more carefully about what materials are used, and how things are produced, is key to combating short-termism,” comments Batch.works founder Julien Vaissieres. “That’s why this kind of collaboration is so promising,”

“We believe 3D printing can be scaled to a wider variety of products, and become a practical manufacturing method for the future.”

The Repair Bot project, conducted by Tradiebot, Swinburne University, and the Innovative Manufacturing Cooperative Research Centre (IMCRC) has achieved a proof-of-concept 3D printing application. Designed by the partners to repair cars, the system has proven its ability to fix headlight brackets, applying 3D printing, scanning, and robotics in the process. Commenting on the development David Chuter, CEO of IMCRC, said it was “amazing” to see how far the collaborators had come since the initial concept was proposed in 2017, adding “Australia is the perfect market for such innovation and this demonstration has been tremendous.”

And, in a new case study from Barcelona-based 3D printer provider BCN3D, the company shows how automated machinery specialist NGNY Devices is using FFF technology in the management of lab equipment. Reportedly saving the company over €40,000 a year, NGNY is using BCN3D printers to develop, test and produce a variety of end-use pieces for its test-tube sorting machines.

University of Birmingham extends its partnership with BAM

In academia, the University of Birmingham has extended its agreement with Germany’s Federal Institute for Materials Research and Testing (BAM). Additive manufacturing is just one of the areas expected to benefit from an ongoing relationship between the two entities, as research focuses on materials characterization, catalytic chemistry, and corrosion.

Elsewhere, in West Lafayette, Indiana, 3D software company Imaginestics LLC has been granted a $1.5 million SBIR grant by the U.S. Navy. The research conducted under this sponsorship will build on a prior project which created an improved system for the force’s management of additive manufacturing.

Students from Loreto College in Mullingar, Ireland have won the ‘Shaping Your Future’ 3D printing innovation challenge. Run in collaboration with the local manufacturing research center IMR, and the I-Form advanced manufacturing center, the winners won a prize for the class and 3D printed trophy for their efforts. The winning project was a key aid called ‘Keyzy’ designed to help people experiencing tremors slot a key into a keyhole and turn the lock.

And the 3D printed Olli bus from LM Industries has entered a trial run at King Abdullah University of Science and Technology (KAUST) in Saudi Arabia.

Dad granted new bionic hand

Bristol-based prosthetic limb designer and manufacturer Open Bionics, has helped a father regain the function of one of his hands. Danny Florence, now 21, lost both legs, a hand and most of his fingers in a bout of meningitis at the age of 5. Now with a son of his own, Florence contacted Open Bionics, and has been granted a bionic hand which he is hoping will help him take care of his child. “I’ve always managed well with only one hand but when my son Joshua came along ten months ago, I realized how much more I could do with two,” Florence said. He will be fitted with the 3D printed bionic hand on December 16.

Californian business consultancy firm Frost & Sullivan has awarded Advanced Solutions Life Sciences (ASLS), a Louisville-based company, its 2019 Bioprinting Value Leadership Award. According to Aarti Chitale, Senior Research Analyst, Life Sciences, Frost & Sullivan, “ASLS is an organization grounded in customer satisfaction & continuous improvement, delivering true value through their market-leading 3D bioprinters. It has developed an extensive ecosystem comprising of biofabrication, vascularization and machine learning software to support adjacent applications in research laboratories to biopharmaceutical factories.”

M. Holland becomes LOCTITE reseller

Following the launch of its LOCTITE brand of 3D printer materials in November, leading global chemical company Henkel has enlisted M. Holland Company as an official reseller. Sam Bail, Head of 3D Printing North America at Henkel Corporation, said, “Henkel is excited to bring M. Holland on board as our 3D distribution partner […] With the addition of LOCTITE 3D resins to the M. Holland portfolio, we believe the partnership will provide M. Holland’s clients new opportunities to use additive manufacturing in their organizations.”

Also in materials, Avid Product Development a product design and 3D printing service bureau in Loveland, Colorado, has added an HP Jet Fusion 5210 system to its facility and will be offering products made from BASF Ultrasint® TPU01.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Sliced logo over a Human anatomy model 3D printed on the Mimaki 3DUJ-553 using Cuttlefish. (Object post-processed for shine). Photo via Cuttlefish/Fraunhofer IGD