Research initiatives dominated the 3D printing sphere in August 2019. These projects ranged from altering the position of .stls in 3D printing to eliminating stair-stepping in FDM.

Eliminating the need for .stls?

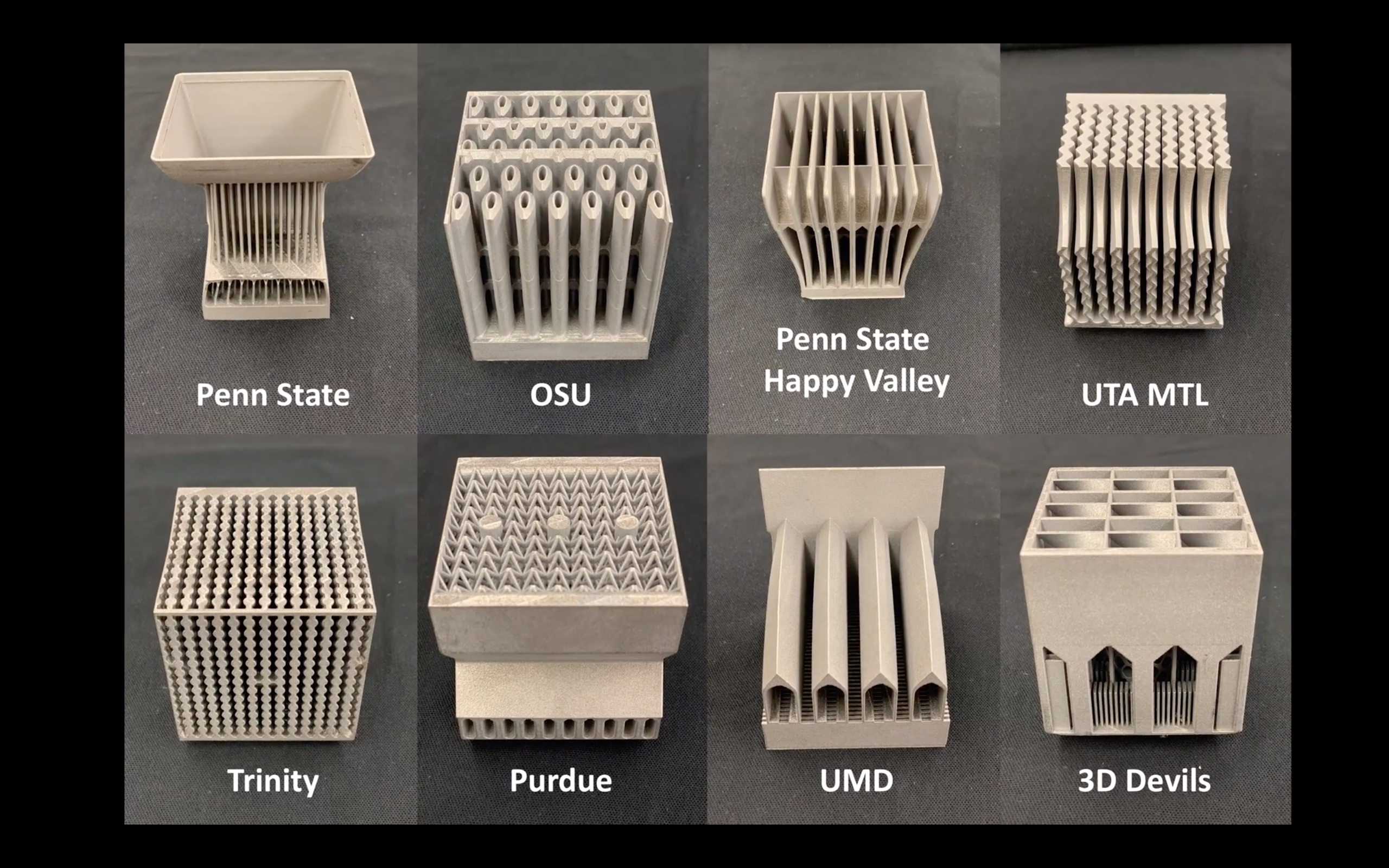

Kicking off this research-focused month is a GE-sponsored competition challenging teams to design a novel 3D printed metal heat sink to effectively cool down electronics, which was our most popular article of the month. The five finalists consisted of teams from Arizona State University, Purdue University, the University of Maryland, Pennsylvania State University, and Trinity College Dublin.

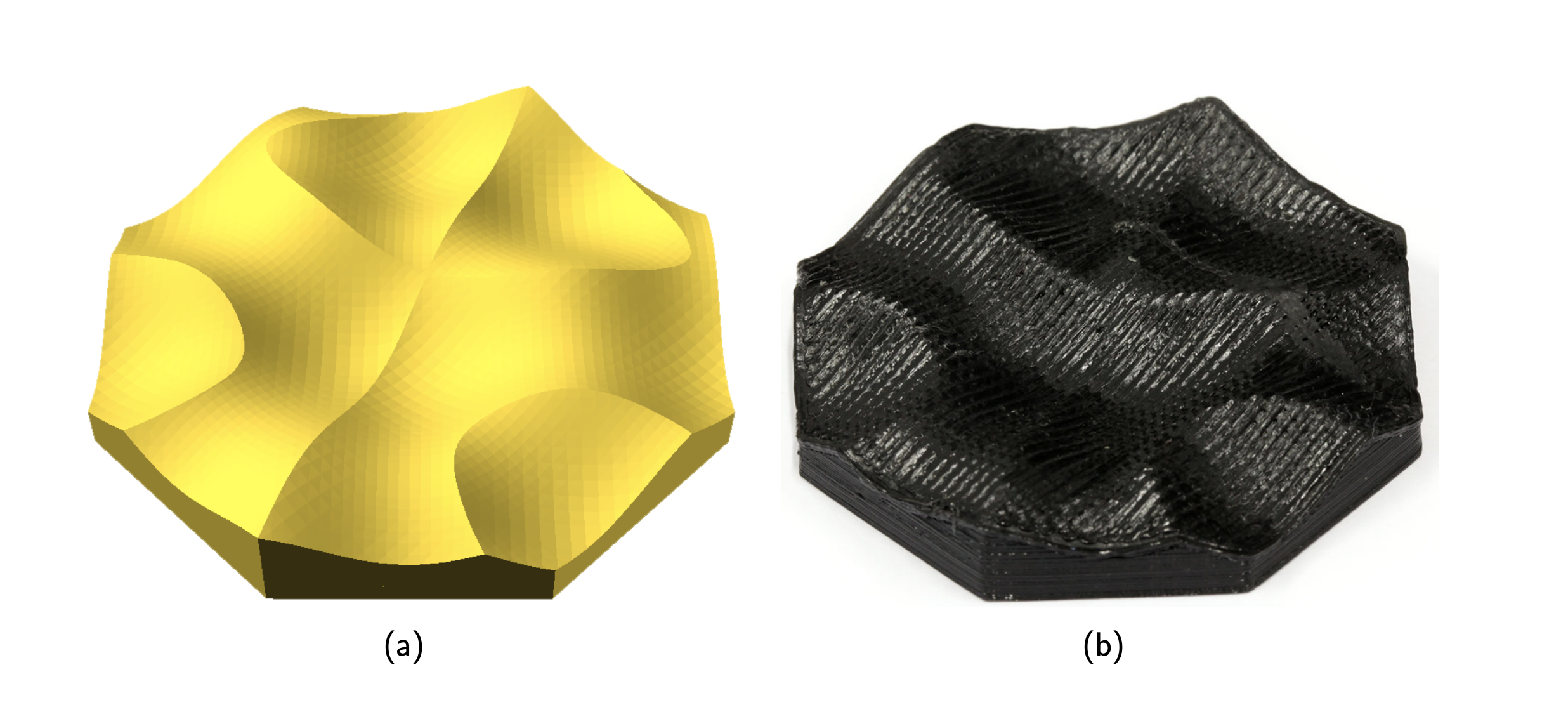

Another one of our most-read articles in August centered on a research project from the University of Hamburg. Researchers there proposed a novel way of slicing 3D printed objects to create smoother results. By 3D printing nonplanar layers close to the horizontal, this slicing method removes the stair-stepping effect typical to FDM surfaces.

Researchers at the Massachusetts Institute of Technology also developed a system to design and 3D print complex actuators. The system consisted of a multi-objective topology optimization software for design synthesis and multi-material drop-on-demand 3D printing for the fabrication of robotic actuators.

Two research projects that were announced in August also focused on exploring alternatives to .stls in 3D printing. A team of researchers from the Virginia Polytechnic Institute and State University (Virginia Tech) developed a 3D printer capable of creating objects using crowdsourced data, known as Source Form. The 3D printer is able to create a 3D model by stitching together database images through photogrammetry, eliminating the need for .stls.

And Joseph Coddington, a masters student at Victoria University of Wellington, conducted a research project to establish voxel 3D printing as a new means of film capture. Coddington’s goals with this experiment could present a valuable alternative to the .stl file.

3D technology in consumer products

In consumer product-related news, Carbon signed a 3D printed product partnership with leading U.S. bicycle manufacturer Specialized in August for a 3D printed bike saddle. This partnership marked the beginning of the ‘Crafted by Carbon’ imprint, which catalogues all of adidas’ consumer applications and collaborations under one brand name, like its 3D printed midsoles with adidas.

Samsung also unveiled its Galaxy Note 10 line of premium smartphones. One of the models came equipped with 3D scanning capabilities, allowing users to scan objects for instant 3D rendering.

3D printer releases in time for TCT Show 2019

Popular 3D printer news from the month came from 3D printer manufacturer Electronic Alchemy, which developed a system capable of additive manufacturing fully functional electronics. Named eForge, NASA intends to use the system during planetary space missions to 3D print chemical sensors on demand.

Airwolf 3D, a California-based 3D printer manufacturer, also announced the release of its latest 3D printer, the EVO R. A new addition to the company’s EVO series of additive manufacturing systems, the EVO R is designed as a smaller and affordable alternative to the EVO and EVO 22.

Finally, Stratasys subsidiary MakerBot launched its METHOD X desktop 3D printer less than 12 months after launching the standard METHOD system. 3D Printing Industry spoke with Nadav Goshen, President and CEO of MakerBot, to learn more about the system: “We planned METHOD X in parallel to provide a more industrial-grade machine to manufacturing professionals,” comments Goshen.

“We believe that both METHOD and METHOD X have their place in the market.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the stacking of different layers of film frames, therefore layers of prints. Image via Joseph Coddington.