Joseph Coddington, a masters student at Victoria University of Wellington, has conducted a project to establish voxel 3D printing as a new means of film capture. Though it may sound bizarre, Coddington’s goals with this experiment could present a valuable alternative to the .stl file.

“This whole project looked at replacing CAD software by using traditional methods such as photography and video,” Coddington explains in an interview with 3D Printing Industry. “Therefore the mindset of a cinematographer and director (for example) were more beneficial to creating this design.”

Bringing the digital back to physical using voxel 3D printing

When a new 3D printing technology, like voxel printing, merges Coddington explained that often feels research surrounding the new process neglects creativity in favor of technical application. Though this makes sense when trying to prove a product’s value to industrial customers, by overlooking artistry Coddington believes the industry may be missing a trick.

As an industrial designer specializing in digital fabrication, Coddington came up with the idea of 3D printing film footage to explore the capabilities of voxel printing. In his research Coddington realized that by 3D printing film footage using voxel printing, he could essentially bring the process of film storage full circle.

Film storage often works by transitioning from analogue or physical film to a digital rendering on a computer. By voxel printing the film storage, he was reversing the order, bringing digital back to physical. “Although it has artistic qualities,” he explains, “this was designed to show the new applications that voxel printing can offer.” He argues that this method demonstrates “the ability to now code the internal structure of materials” which “offers a range of new applications in multiple disciplines.”

A complex and layered 3D printed film

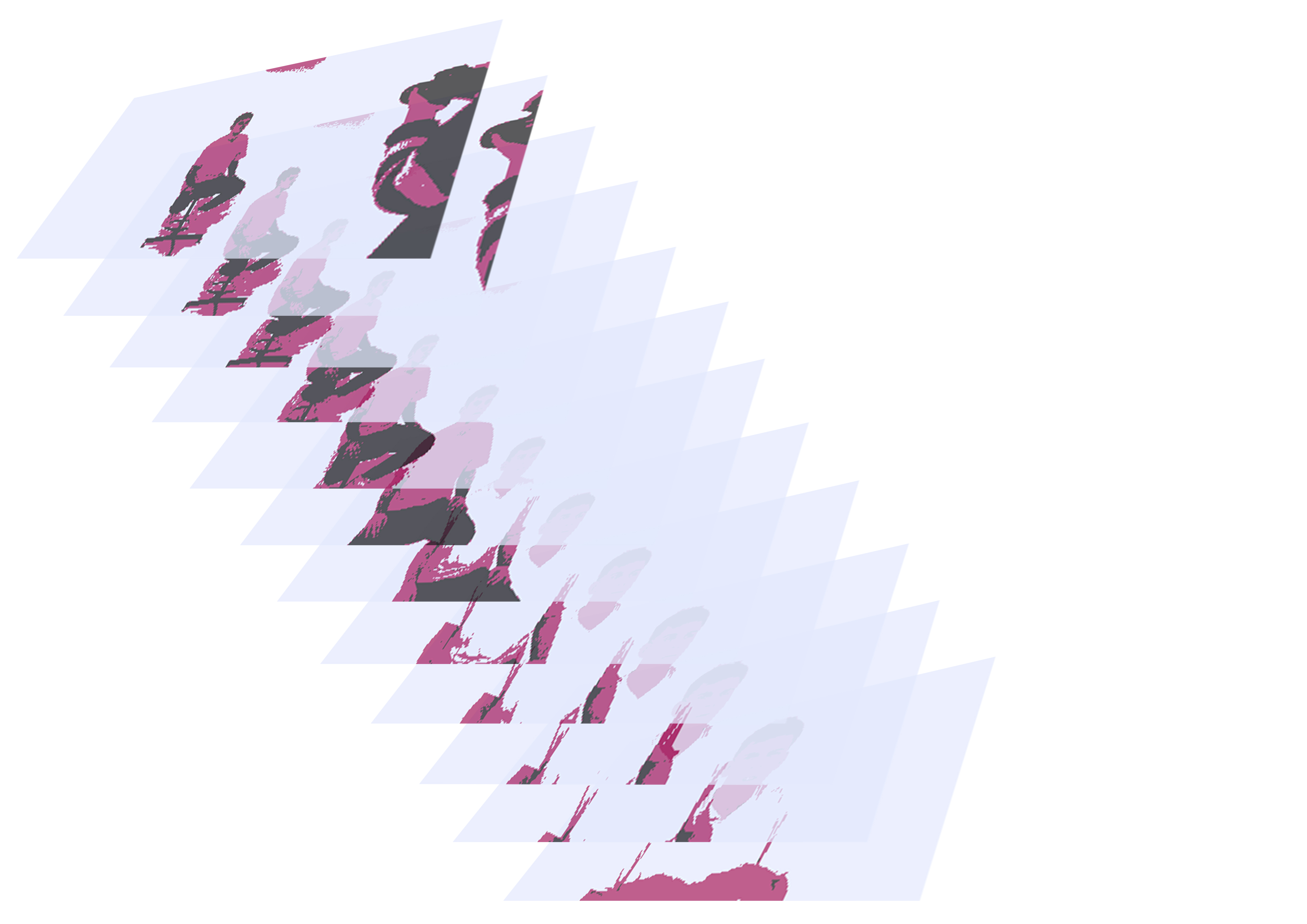

Coddington’s voxel 3D prints are composed of several hundred layers of exported film frames stacked upon each other, obtained from a 32 second video of the researcher himself getting his portrait taken. The video pans over to Coddington, while also containing a secondary character, to capture a range of movement and visualize a scene on the 3D print. Calculations were used to determine the depth of the 3D print, which in this instance, is representative of time within the film – more frames means more layers, and therefore increased depth and a longer film.

The process of slicing the video required Coddington to export every 30th frame of the video as a PNG image. Using more frames would increase the cost of the 3D print due to increased build height. Setting up the images for 3D printing did not necessitate the allocation of specific properties to each pixel as it has already been given positional data due to the film, and colour data via editing.

Likening the filming process to CAD modeling, Coddington states that though “you can definitely create forms that reflect film footage, without CAD and .stl files,” this method “it would not replace them outright as .stl files still offer a lot of artistic and building freedom.” The end result is a small rectangular brick, containing a pink silhouette which can clearly be seen moving across the frame. Though blurry, the object is a good demonstration of the 3D printer’s (in this case a Stratsys J750) voxel-by-voxel control.

The key to multimaterial 3D printing

As highlighted in Coddington’s project, 3D printing by the voxel presents a great deal of potential, not only for the aesthetic of an object, but also its mechanical properties. At MIT’s Mediated Matter Group, researchers led by Neri Oxman have patented a method that translates point cloud data into a pixel-by-pixel approach for multimaterial 3D printing. Putting this method into practice, the lab collaborated with Wyss Institute for Biologically Inspired Engineering at Harvard University to produce highly detailed anatomical models which can be used to better understand a patient’s condition.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also keep connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows 3D printed film footage. Photo via Joseph Goddington.