Less than 12 months after the launch of the METHOD, desktop 3D printer provider MakerBot has launched the METHOD X. A new addition to the METHOD line of machines, the METHOD X has been made to fill a niche in the market between desktop and industrial systems, identified by MakerBot as “Performance” 3D printers.

Speaking with Nadav Goshen, 3D Printing Industry learns more about the new release and what the METHOD X brings to the market.

MakerBot heads for professional market

Launched December 2018, the MakerBot METHOD is the first 3D printer from the company since former CEO Jonathan Jaglom stepped down from his post in 2017. At this time, Goshen took control of MakerBot and undertook a market assessment to find the company a lucrative position within the highly competitive desktop market.

Inline with parent company Stratasys’ aims, the decision was made for MakerBot to pull focus to professional and educational markets for 3D printers, rather than the niche hobbyist and consumer track it had been following since its foundation in 2009. Speaking to Goshen at the time of the METHOD line launch, he told me that MakerBot is looking to “rebuild its core competence” in light of the market.

How does it compare the METHOD?

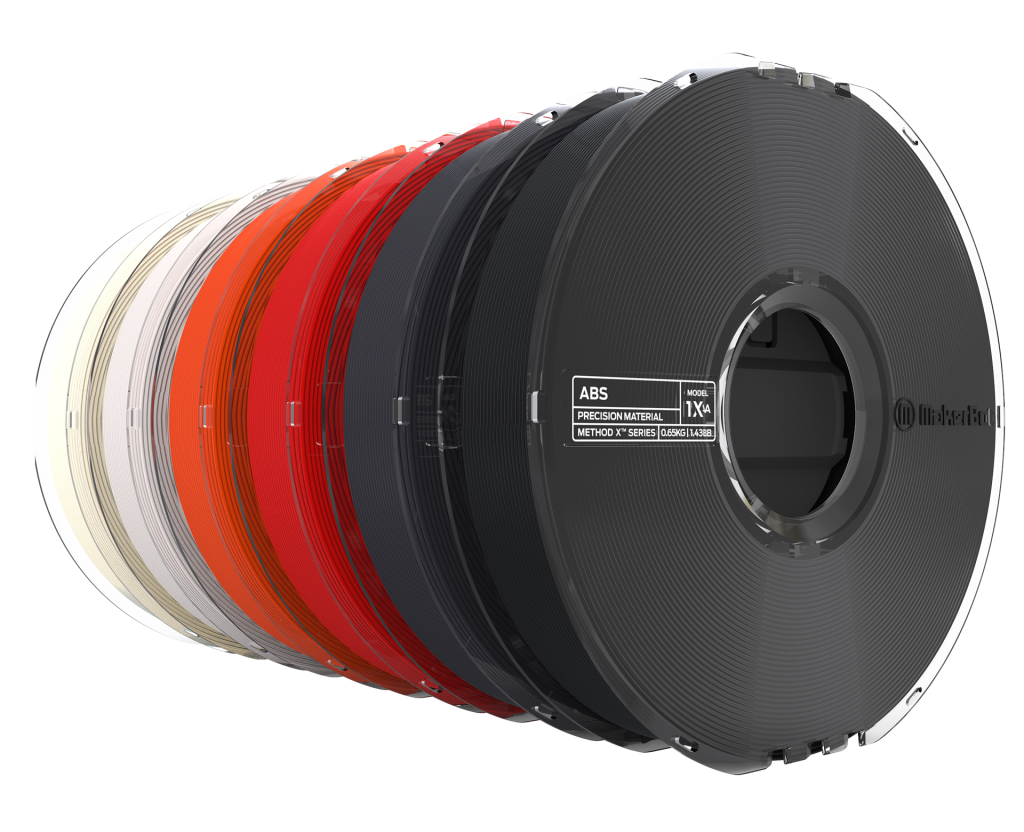

The main difference in the METHOD X when compared to the original METHOD is that it is capable supporting more challenging materials. It has a 100°C Circulating Heated Chamber, making it possible process a METHOD X ABS. In internal testing, METHOD X ABS has shown to be up to 26% more rigid, and up to 12% stronger than modified ABS formulations used by competitors. The material also reportedly withstands 15°C higher temperatures than the next leading brand ABS. As the METHOD is a line of dual extrusion 3D printers, METHOD X ABS can be 3D printed simultaneously with SR-30, a soluble support material from Stratasys. In addition, like the original METHOD, the system is also capable of 3D printing objects in MakerBot PLA, MakerBot TOUGH, MakerBot PETG, and MakerBot PVA.

Is there room for more METHOD machines?

For the majority of specifications, the METHOD and the METHOD X are the same, as Goshen states, “METHOD and METHOD X are the two variants within the METHOD family of 3D printers. Both printers offer measurable and repeatable dimensional accuracy (±0.2mm / ±0.007in) that is on par with entry-level industrial 3D printers.”

With base values the same, it then begs the question – why did MakerBot release the METHOD X as a new system? And not simply make it an upgrade for the original METHOD which has already shipped to hundreds of customers? According to Goshen, this has always been the plan. “We planned METHOD X in parallel to provide a more industrial-grade machine to manufacturing professionals,” he said, adding that “METHOD X took longer to develop due to the higher chamber temperature and additional mechanical and electrical requirements.”

Further, Goshen says, “We believe that both METHOD and METHOD X have their place in the market.” Adding a Circulating Heated Chamber has, of course, raised the cost of the machine. By releasing the original METHOD first, without this added cost, mean that the industrial features boasted by this line of machines could be offered within a lower price bracket. “The different features and price points allow us to cater to different customers,” Goshen says by way of explanation. “METHOD has a lower entry-price to get started with the METHOD platform for design engineers who are mainly interested in concept and fit prototypes that don’t need ABS.” The METHOD X, on the other hand “provides true production-grade ABS for manufacturing and design engineers who create end use parts, manufacturing tools, and functional prototypes.”

METHOD X availability

The METHOD X was launched early this week following Q2 2019 financial results from Stratasys within which the company spoke favourably of the success of the METHOD. The first shipping of the system is scheduled to begin at the end of August 2019. Currently a beta program for the METHOD X is underway.

For all of the latest 3D printer releases subscribe to our newsletter, follow us on Twitter, and like us on Facebook. Find talent for a project, or advance your career in 3D printing – join 3D Printing Jobs to apply and advertise.

Featured image shows the MakerBot METHOD X. Photo via MakerBot