Kumovis, a German medical 3D printing startup, has announced the commercial availability of its first 3D printer, the R1.

The new system uses fused layer manufacturing (FLM) technology, and is geared towards use in the healthcare sector. Kumovis has designed the 3D printer to provide a solution for manufacturing patient-specific medical devices and prototypes using high-performance plastics like PEEK. Employing such materials, the company believes medical professionals can gain access to innovative healthcare products that meet the tough regulations of the medical industry in a resource-efficient way.

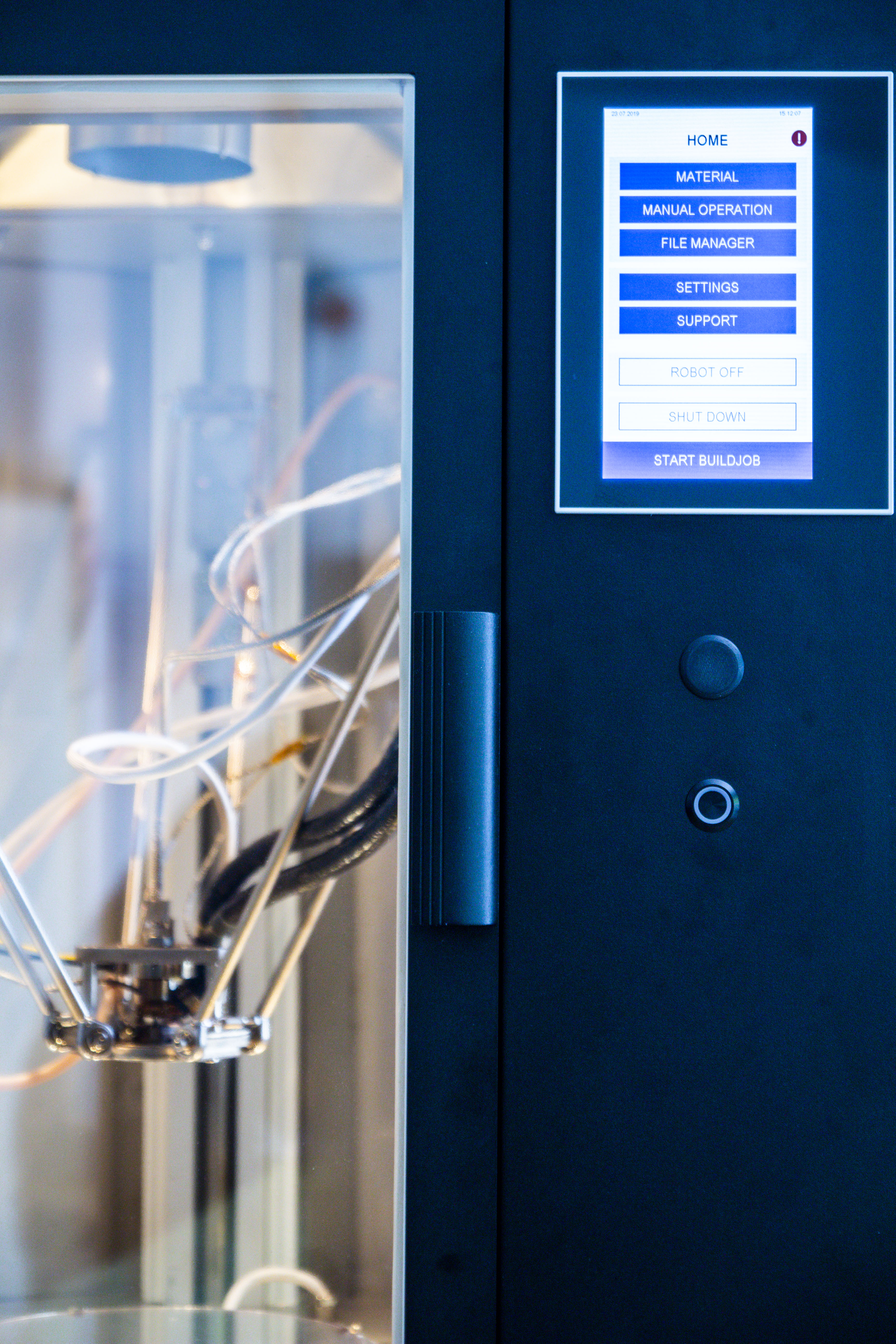

Key features of the R1 3D printer include a temperature control and filter system, allowing users to create a “clean room” environment in the build chamber. The R1 also uses print control from Hyperganic, a German 3D printing software company, helping to optimize the system processes. Currently, three R1 3D printers are already in use at pilot customers. Stefan Leonhardt, co-founder of Kumovis, stated:

“With the Kumovis R1, we are excited to provide medical technologists with a resource-efficient additive manufacturing system that meets their high requirements, and what is more, leads FLM processing of high-performance plastics to industrial maturity.”

The R1 3D printer

Kumovis’ R1 3D printer features a patented temperature management system that allows for homogenous heating, which improves layer adhesion. The user is able to raise the temperature of the build chamber up to 482°F (250°C). Customers also have the choice of an optional filter to prevent foreign particles from entering the build chamber, thereby averting defects in the component. Kumovis likens the effect of the filter to the establishment of a clean room, which are classified clean environments often used for medical research purposes. The optional R1 filter system helps the 3D printer produce products that meet the strict requirements for manufacturing patient-specific medical devices.

The cooling system equipped on the R1 allows for the manufacturing of parts with good reproducible mechanics and dimensional accuracy. This is necessary for the production of adaptive medical implants, in turn improving the patients’ healing process. Kumovis credits the effectiveness of the cooling system in part to the Hyperganic Print software.

Lin Kayser, Managing Director at Hyperganic, commented, “Hyperganic works closely with printer manufacturers to enable far-reaching innovations. From the beginning, I have been impressed by the vision of the Kumovis founders to reinvent additive manufacturing for medical applications through new materials and advanced process technology. We are convinced of that and look forward to intensifying our collaboration with them.”

The print control program from the German software company uses algorithms to generate and design parts and structures that are complex and functional. Equipped in Kumovis’ R1 3D printer, the Hyperganic Print software allows users to optimize prints across the part, as well as customize and automate their processes. “With partners such as the software experts from Hyperganic, we will be able to provide rapid access to individualized medical products, and consequently help creating added value for patients and doctors alike,” added Leonhardt.

Hotly tipped Kumovis medical 3D printing technology

Kumovis was founded in 2017 by Miriam Haerst and Stefan Leonhardt, as a spin-off from the Technical University of Munich. The company has been developing its R1 3D printer for some time, and had always set its sights on creating a medical 3D printer viable for use with high-performance polymers like PEEK.

It’s ambitious vision has not gone unnoticed. The company has the backing of TU Munich, the European Space Agency, and several other organizations. It was listed among the winners of the Formnext 2018 Start-Up Challenge, alongside several other promising companies. Kumovis’ technology also helped it win the Munich Business Plan Competition 2018.

Speaking with 3D Printing Industry in 2018, the company discussed the objectives of the R1 3D printer: “We have set ourselves the goal of enabling the additive production of medical products through new 3D printing solutions. To reach this goal we focus on the processing of high-performance polymers […] With the Kumovis system these plastics can be processed patient-individualized, time and cost efficient while entailing a high level of design freedom.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also keep connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows front view of Kumovis R1. Photo via Kumovis.