Europe’s largest 3D printing exhibition formnext has decided the winners of its 2018 Start-Up Challenge.

This year, 3D Printing Industry sponsored the competition and our Editor in Chief Michael Petch was on the jury to select the top five inventive and viable 3D printing startups of 2018.

This year’s prizewinners are: Fortify, Aerosint, AMendate, Kumovis and Nanogrande.

Fortify Digital Composite Manufacturing

Fortify was founded by Northeastern University graduates to, “optimize the microstructure of composite materials,” and “to make optimized composites easy to fabricate.” Based in Boston, Massachusetts, the company has developed its proprietary Flexprint technology combining magnetics with digital light processing (DLP) to accurately manage the alignment of composite fibers.

Karlo Delos Reyes, Co-Founder and VP Business Development at Fortify, comments, “It’s an exciting time to launch a venture in 3D printing, and we feel that we have a differentiated and compelling technology for a wide-variety of applications,”

“We’re excited to be presenting at the show and to showcase Fortify’s Digital Composite Manufacturing to the greater Formnext community.”

Aerosint multimaterial SLS 3D printing

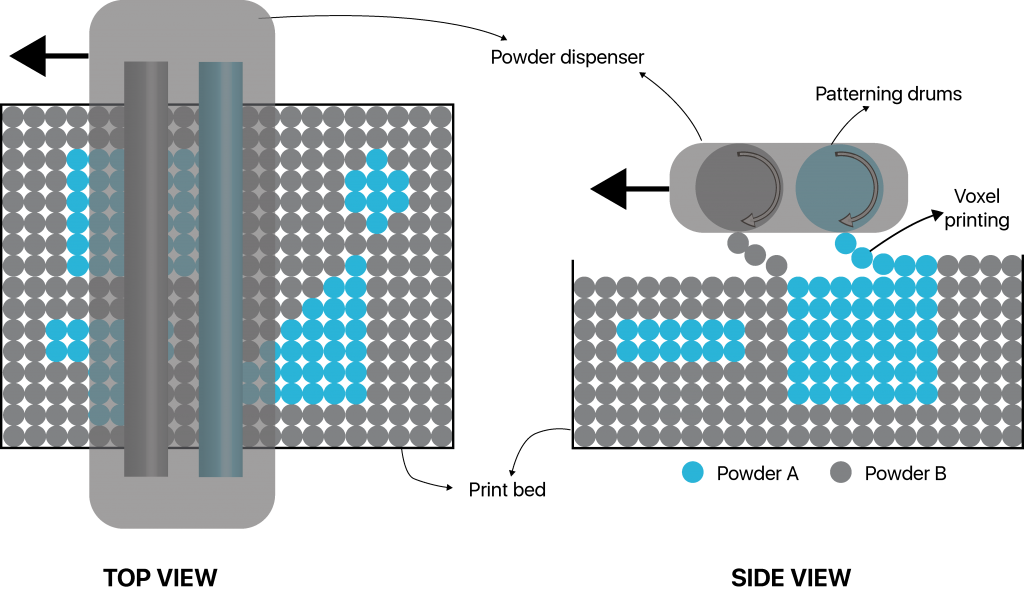

Headquartered in Liège, Belgium, Aerosint is a startup with a patent-pending selective laser sintering (SLS) technology that enables the simultaneous 3D printing of more than one powder. The company’s dual powder dispenser is an add-on, custom built for installation inside ready-made polymer powder 3D printers.

In response to the company’s prize winning at formnext 2018 Matthias Hick, CTO of Aerosint, says “…we believe multi-material is the next evolution of 3D printing. Multi-material will enable parts optimization and functionalization like no other manufacturing technology is capable of. Replacing the traditional recoater in SLS/SLM printers with our powder deposition recoater can bring multi-material capabilities to a robust and proven technology that exists for more than 30 years.”

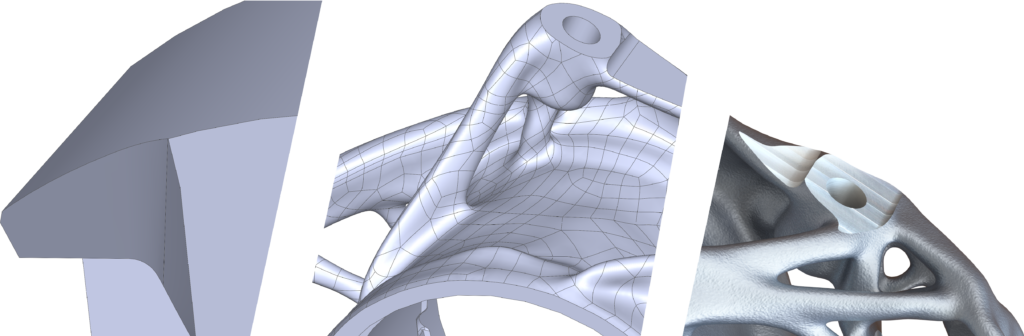

AMendate topology optimization software

AMendate provides an automated topology optimization tool for additively manufactured component designs. The company is based in the West-German city of Paderborn, and operates with funding from the EU, the Federal Ministry for Economic Affairs and Energy (BMWi) and three other European organizations.

Thomas Reiher, CEO and Co-Founder of AMendate, comments, “As one of the winners of the Start-up Challenge, we are therefore delighted to be part of the industry’s must-attend event. AMendate develops a solution for the automated optimization of structural parts. This is an ideal solution for companies that need parts which take optimum advantage of additive manufacturing. We expect interesting technical discussions and hope for exciting orders.”

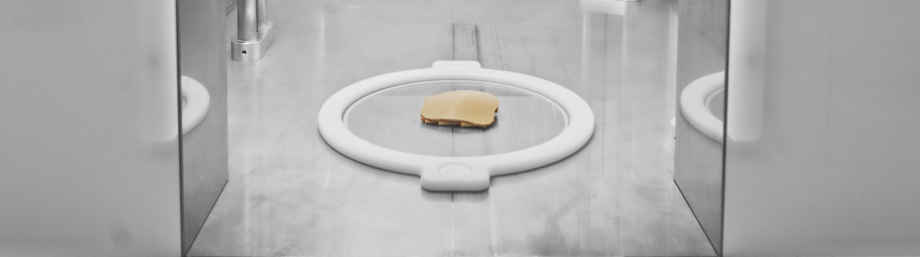

KUMOVIS medical-grade polymer 3D printing

KUMOVIS, based in Taufkirchen, Germany, is developing an FFF based 3D printer for the medical industry. The company’s goal is to make it more economically viable to 3D print using high performance polymers like PEEK, and has the backing of TU Munich, the European Space Agency, and several other organizations.

Miriam Haerst, Managing Partner at KUMOVIS, comments, “At Kumovis, we want to use our technology to enable a new generation of implants tailored to patients’ needs. We offer an end-to-end solution for a market that presents regulatory challenges. We are pleased that we will be presenting our Concept Clean AM system to visitors at Formnext in November.”

Nanogrande molecular additive manufacturing

Based in Quebec, Canada, Nanogrande is a high definition additive manufacturing company. According to the company, it has developed “the first Molecular Scale Additive Manufacturing system,” that works with non-spherical and unconventional powders. The company will be introducing its technology at formnext 2018.

Juan Schneider, Founder and CEO of Nanogrande, says, “We are looking to meet and share fruitful ideas with the attendees, the visitors and other exhibitors. But our foremost goals are to establish commercial links, open the doors to investors and pave the way for some sales. We are convinced that Formnext is only the beginning of our adventure with Europe.”

Former prizewinners

In addition to a free booth in the formnext 2018 startup area the winners of this year’s challenge have been added to the MUST 3D Printing network alongside other startups such as Flex Wheel Extruder, 3YOURMIND, and Additive Works, and founding partners EOS, UnternehmerTUM and SCE.

Each business will receive coaching sponsored by AM Ventures, and also a company profile on 3D Printing Industry – the leading 3D printing news platform with the largest newsletter subscription in the industry.

Previous winners of the formnext Startup Challenge include color and post-processing specialist Dye Mansion, desktop SLS developer Sinterit and the UK’s Additive Manufacturing Technologies (AMT) for its post-processing technology.

For all of the latest updates direct from formnext 2018 and other leading industry events subscribe to the 3D Printing Industry newsletter, and join us on Facebook and Twitter.

Find your next career move or find new skilled additive specialists with 3D printing jobs.

Featured image shows 3D printed trophies for the 2017 Startup Challenge. Photo via formnext