In this edition of our 3D printing news digest Sliced, a 3D printed hypercar, further investment into hypersonic flight enabled by additive manufacturing, a new and advanced 3D printer for the medical sector and recent partnerships from Fisher Unitech and Nano Dimension, as well as Bowman International and HP.

Also included is additive manufacturing news from Xometry, Boeing, Shining 3D and an alligator called Mr. Stubbs.

Hypersonic flight receives a boost from Boeing

Earlier this year, Boeing joined a $37 million investment in British rocket startup Reaction Engines, who are currently working on the 3D printing enabled SABRE engine and future hypersonic travel.

Nano Dimension partners with Fisher Unitech

In order to expand its channel network, Nano Dimension, an Israeli additive manufacturing technology company, has partnered with Fisher Unitech, a U.S. 3D printing technologies provider.

Within this reseller agreement, Fisher Unitech will purchase Nano Dimension’s proprietary DragonFly 2020 Pro 3D Printer with intentions to make the technology available to its large customer base.

This is Nano Dimension’s third channel partnership in North America, which closely follows its expansion into the Asia-Pacific market through a strategic agreement with the AURORA Group, a Taiwanese distributor of additive manufacturing systems.

“This partnership represents significant growth potential for both companies. Nano Dimension’s technology forwards our mission to fundamentally advance manufacturing in America by adding the most advanced 3D printed circuit board technology to our customers,” said Matt Wise, CEO of Fisher United.

3D Printing studio for kids

A 3D printing studio has been opened in the Rogue Valley Mall, located in Medford, Oregon. iPrint 3D Studio will sell 3D printers, 3D printed objects, and offer in-store printing for customers with personalized blueprints. Owners of the studio, Ron and Carolyn Triplett will also host educational classes for children interested in 3D printing.

“We decided to get involved with the children because this kind of technology is going to be great in the future when it comes to architecture, 3D gaming, software engineers, all sorts of different things,” said Ron Triplett. “This is going to be able to give the kids a heads up to start their careers in the future.”

iPrint 3D Studio classes will begin later this month; a schedule of the classes can be found here.

Additionally, Texarkana College, based in Texas, has received $20,000 from the Arconic Foundation, to purchase the AXIOM 3D Dual Direct Printer and the EVO Additive Manufacturing Center.

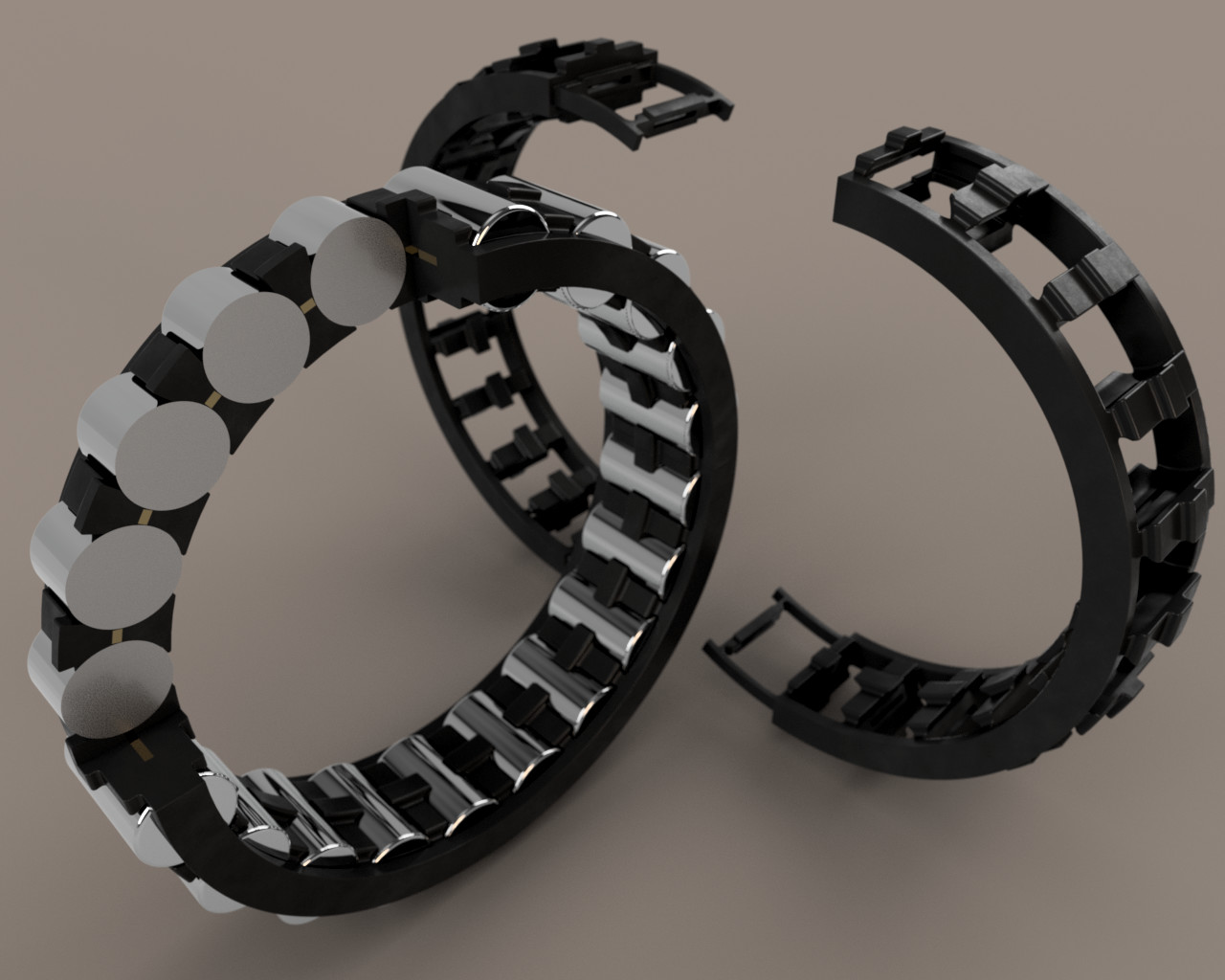

Bowman International adopts HP Multi Jet Fusion 3D printer

Bowman International, UK supplier and manufacturer of plain bearings and sintered parts, has reduced its production costs and increased functionality with its new HP 4200 Multi Jet Fusion 3D printer.

With this 3D printing technology, Bowman International has also created a solution for the production of its bearing cages, including the Rollertrain cage.

“The Rollertrain cage combines the very latest in 3D printing with world-renowned materials science,” said Jacob Turner, Head of Bowman Additive Production.

“Together, this offers OEMs and plant maintenance engineers a split bearing which delivers superior performance and longer product life, alongside simplified mounting and maintenance procedures – not forgetting less vibration and noise during operation.”

$3.6 billion missile site to support future additive manufacturing projects

U.S. Senator Robert Portman has told members of the Eastern Ohio Military Affairs Commission (EOMAC) at the group’s annual meeting that a decision on the placement of a $3.6 billion missile defense site at Camp Ravenna is coming “pretty soon.”

The EOMAC has worked closely with the Youngstown Air Reserve Station (YARS) to support, military missions within eastern Ohio, which have included several 3D printed projects for part replacements. During the meeting, U.S. Representatives Bill Johnson and Tim Ryan, emphasized the YARS’ work with additive manufacturing to produce replacement aircraft parts.

“We want this base to be part of the intellectual future of the military,” said Ryan. “We’re already seeing preliminary results of the investments in additive manufacturing. You can go to Kuwait, to Bahrain and the Air Force is there without the ability to access parts for the plane.”

Before its establishment, the Missile Defense Agency must decide whether the East Coast Missile Defense System is necessary. This recommendation will take 90 days.

Italian politician doesn’t understand 3D printing

Speaking to the press last week, Italian Deputy Prime Minister Luigi Di Maio has stated that the plans to build a Franco-Italian railway line, known as TAV, had to be reviewed due to community opposition. In a statement that might raise a few eyebrows as to the full understanding by the politician of technology, Di Maio expressed that TAV and other traditional freight transportation is now obsolete as a result of new industrial manufacturing technologies, i.e., 3D printing.

In other news, the Community Trust and Investment Company (CTBI), based in Kentucky, has decreased its stake in Boeing by 13.61% according to its latest 2018Q1 regulatory filing with the U.S. Securities and Exchange Commission (SEC) due to Boeing’s 0.93% stock declined within the market.

Xometry, an on-demand manufacturing platform, has introduced Stereolithography (SLA) to its list of 3D printing capabilities.

3D printing and the healthcare sector

German medical technology developer, Kumovis, has won the Munich Business Plan Competition 2018 with its PEEK 3D printer specially designed for medical technology requirements.

With an integrated temperature-controlled air circuit including filter units, the technology allows a clean room environment within the installation space – preventing component contamination – for the production of skull plates or spine implants.

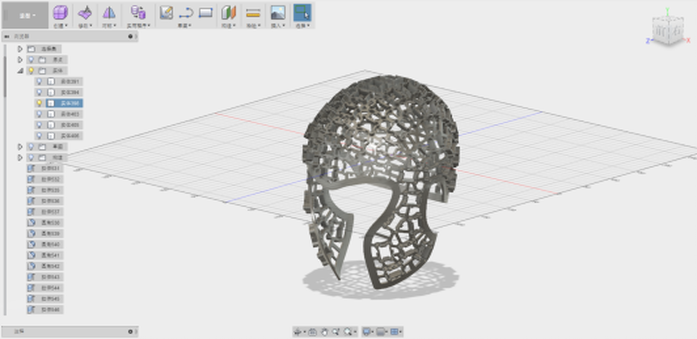

Shining 3D’s EinScan-Pro 3D scanner has been utilized by China’s Prod-lab to build a tailor-made helmet for brainwave research. Using the data from the 3D scan, researchers created a 3D printed helmet that can potentially receive brainwaves.

“Shining 3D’s scanners [bring] fast scanning speed and high-accuracy 3D data. The future relationship between brainwave research and 3D digitizing and 3D printing will be even closer, we are looking forward to creating more innovation,” stated Shining 3D.

The Department of Orthopaedics at Kasturba Hospital in India has opened a new 3D printing facility which will manufacture artificial limbs.

This new department has already provided two children 3D printed prosthetics and doctors at Kasturba Hospital are now encouraging parents within the town of Manipal who require prosthetics for their children to contact its orthopedics department.

In other medical 3D printing news, a recent study entitled “A Proposed Method for Producing Embossed Dots Graphics with a 3D Printer” has produced 3D printed customizable braille.

The PeakBoil camping stove

Students and a doctoral candidate at ETH Zurich have developed a camping stove with a central flame system using SLS additive manufacturing. The kettle shaped tin named “PeakBoil” surrounds a gas burner, which protects it from strong winds.

The PeakBoil recently won a prize in the 3D Pioneers Challenge competition for its innovative design. Julian Ferchow, the project leader and a doctoral student at ETH explained:

“This technique (SLS) gives us a huge amount of design freedom, which you just don’t get with conventional manufacturing techniques; with metal casting, for instance, we could never achieve channels that are as thin as the ones inside our gas burner.”

Manufacturing a bionic human

Youbionic, an Italian robotics company, has created a bionic 3D printed arm equipped with robotic mechanisms to enhance human motor skill capabilities.

This invention is part of Youbionic’s Augmented Human project which intends to make devices that extend the human lifespan by merging the biological body with mechatronic components.

The Blue and white project

Netherlands designer, Olivier Van Herpt, has 3D printed a series of blue and white thin-walled vases that pay homage to Delftware, a centuries-old style of pottery.

Milan Automotive, Austrian-based car manufacturers, has unveiled its first carbon fiber hypercar, the Milan Red. With a weight of 1,300 kg, the body panels, chassis, suspension components, and wheels are made using the SLS process.

An alligator’s tale

Researchers from Arizona’s Midwestern University, have created a 3D printed tail for a physically handicapped alligator aptly named “Mr. Stubbs.”

In 2008, the seven-foot alligator was found and rehabilitated by a non-profit animal rescue organization, the Phoenix Herpetological Society. However, due to his disability, Mr. Stubbs was able to swim or access food as well as other alligators.

Becoming aware of Mr. Stubbs’ circumstances, the Midwestern research team created a basic silicon tail prosthesis in 2013. Nevertheless, the team was called to revisit the Phoenix Herpetological Society as Mr. Stubbs outgrew his prosthetic.

“We contacted the 3D scanning and printing company Stax3D to find out what they could do to help us,” said Dr. Justin Georgi, Associate Professor of Anatomy at Midwestern University.

“They used an Artec 3D scanner to create a high-resolution, digital model of the tail. We [were able to] manipulate that model to produce any alteration to the tail we needed. We fixed imperfections, made it exactly the correct length and size, [and] adjusted the front end so it matched Mr. Stubbs’ stump with a perfect custom fit.”

Weston Beamor builds additive manufaturing team

UK-based jewelers,Weston Beamor, have added Sarah Parry, graduate from Birmingham City University’s School of Jewellery to its 3D printing team due to an increase in customer demand for personalized jewelry. Additionally, existing team members Anousca Hume and Richard Vinten have received a promotion to Senior CAD Designers.

“We’re focused on ensuring that our team can respond to this demand and deliver the high-quality product with industry-leading service that our customers have come to expect,” said Ed Hole, Business Manager at Weston Beamor.

The Venturi3D printer

Venturi3D, a Florida-based 3D printer startup, has launched a Kickstarter campaign for its multi-material and consumer-friendly 3D printer. The Venturi 3D printer also features 1,000 ready-to-print models pre-installed within its system.

“We’ve set out to radically re-define what a 3D printer can do and finally push the industry in a new direction,” stated Christopher Lane, Founder of Venturi 3D. “Our goal is to allow anyone to be able to push a button and print beautiful, useful objects.

The Adidas X Invincible Prism 4D sneaker

Following the release of Adidas and Carbon’s futurecraft 4D sneakers, Adidas and Invincible, a Taiwanese sneaker boutique, have unveiled the latest addition to the futurecraft 4D line with its “Prism” collaboration. The Adidas X Invincible Prism 4D sneaker includes a signature light green 3D printed sole.

Lastly, ASIMET, a South American metallurgical consultancy, has stated that “advanced manufacturing is key for Chile to compete globally” at its annual industry forum which took place last week.

Keep up with the latest news in 3D printing by subscribing to the 3D Printing Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

Looking for a change of pace? Seeking new talent? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows the sliced logo over the Milan Red carbon fiber hypercar. Photo via Milan Automotive.