Since its inception, 3D printing has had its challenges. Before the release of the HP Multi Jet Fusion 3D Printer, the technology was constrained by slow production times, inferior part quality and limited material options.

In 2016, the HP Multi Jet Fusion 3D Printer changed all of that. Jet Fusion technology was not as much a development in 3D printing as it was a reinvention of it, and this technological leap essentially redefined 3D printing for prototypes and manufacturing.

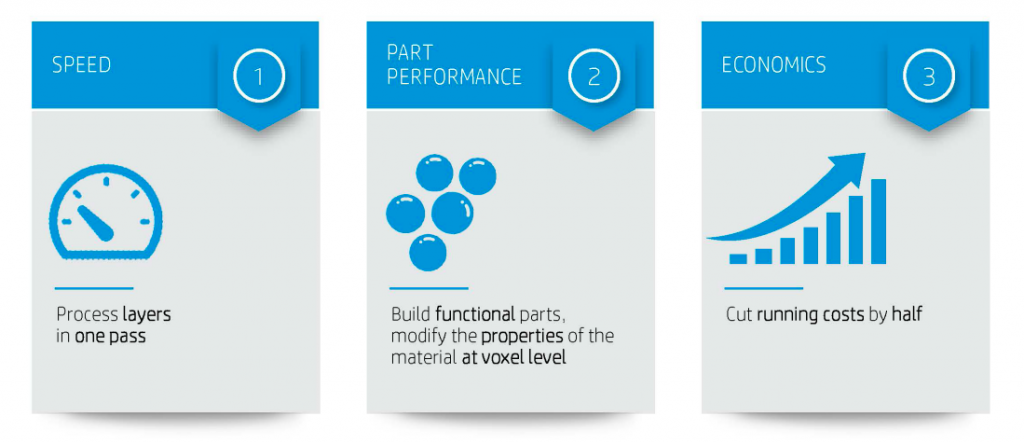

Speed, quality and affordability seem to be the main themes of the HP Multi Jet Fusion 3D Printer, and HP achieved these advantages in very specific ways.

Thermal InkJet Technology

As a leader in Thermal Inkjet printing, it’s no surprise that HP utilized this technology in its Multi Jet Fusion 3D Printer. This distinctive approach unified and integrated the printing process to reduce time, cost, energy consumption and waste.

Thermal Inkjet technology maximizes efficiency by delivering print agents across an entire work area. It also simplifies the steps involved in post-processing to allow for industry leading recyclability of build materials.

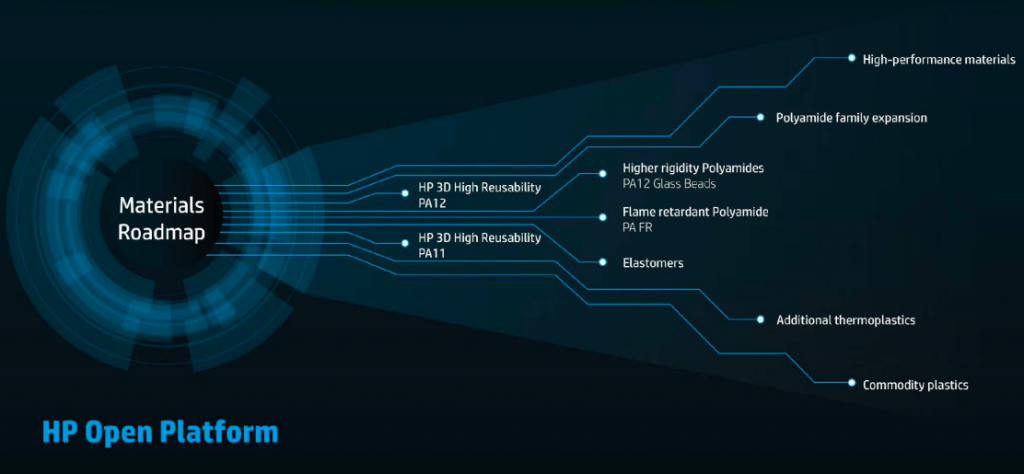

The Open Material Platform provides unmatched potential for upgraded material performance and reduces material cost by up to half. The initial material released on the platform is HP’s own 3D High Reusability PA12, an engineering-grade thermoplastic material that produces mechanically sound parts without sacrificing cost or part quality. In order to fully maximize the potential of its Jet Fusion printing platform HP is leading the industry in the endeavor to reduce costs, increase quality and minimize waste by partnering with leading research firms that will develop their own Jet Fusion certified materials. The Open Material Platform will help HP drive adoption of additive manufacturing applications on a much wider scale.

Jet Fusion technology is what makes printing at the voxel level possible. A voxel, representing a value on a regular grid in a three-dimensional space, can vary in color, texture, wear and friction. Looking forward The Jet Fusion 3D Printer’s ability to control mechanical properties at the voxel level results in unrivaled flexibility for 3D printed parts.

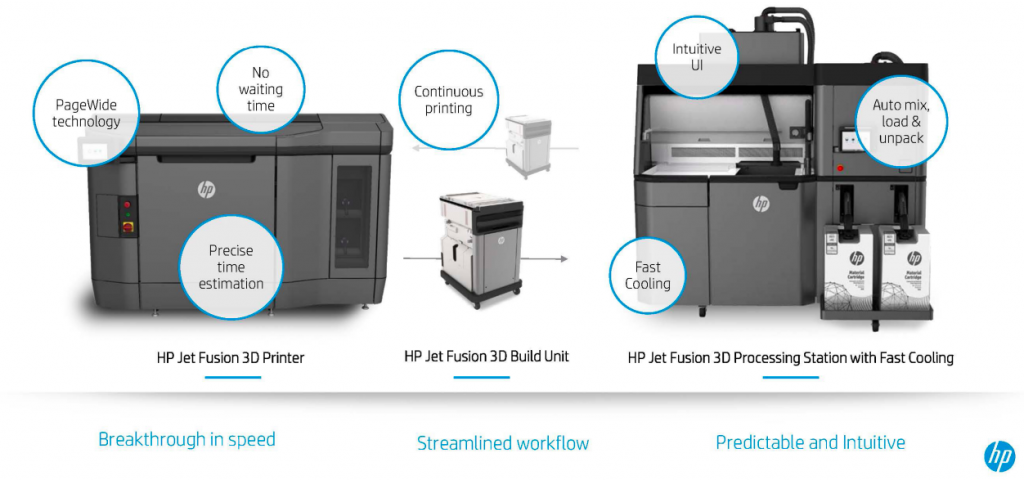

Continuous Production

Perhaps even more impressive than warp printing speeds of 30 million drops per square inch—or 340 million voxels—per second is the Jet Fusion 3D Printer’s ability to print continuously. Not only is this printer working up to 10 times faster than its closest competitors in the 3D market like FDM and SLS, but it’s also outperforming them in total throughput thanks to a closed loop printing and post-processing system. Fast-cooling capabilities with multiple build units allow for high-volume continuous printing and decreased time lapsed from concept to part.

Holding to the belief that a product is only as great as its level of support, HP Technical Services and Support offer next-business-day, on-site support so that businesses can keep their HP 3D printing machines running at high capacity without waiting for costly repairs or technology upgrades.

Additionally, HP capitalizes on customer support by partnering with local resellers like TPM, which anticipate and prioritize their clients’ needs. Matt Luther of TPM says, “The feedback from our customer base on the overall ease of operation of the Multi Jet 4200 system and the quality of the parts coming off of the platform has been extremely positive.”

Productivity, affordability, and sophistication rarely come together in one product. The HP Multi Jet 3D Printer has reinvented 3D printing. The question now is whether others in the industry will keep up.

To download an exclusive eBook that illustrates every detail you’d ever need to know about this revolutionary machine all in one place click here, or on the graphic below.