3D printed buildings on Mars are a stage closer with NASA’s announcement of the latest results in its 3D Printed Habitat Centennial Challenge.

In conjunction with the Bradley University of Peroria, Illinois, the Habitat Challenge invites proposals for 3D printed off-world structures that can be made with the kind of materials available on Mars.

Monsi Roman, program manager for NASA’s Centennial Challenges, said, “They are not just designing structures, they are designing habitats that will allow our space explorers to live and work on other planets. We are excited to see their designs come to life as the competition moves forward.”

Transporting materials to Mars

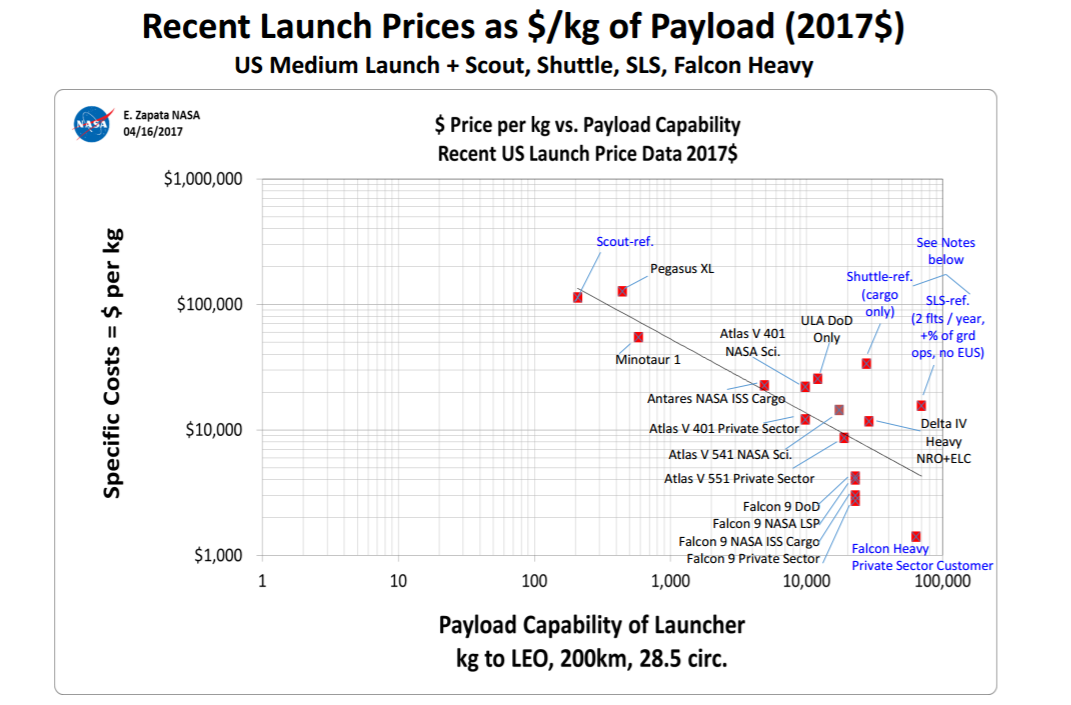

Considering the limitations and costs of transporting materials to Mars, using in situ resources is an area of considerable research activity. For example, NASA data shows that using the Antares NASA ISS Cargo it costs over $10,000 to put a kilo of payload into a Low Earth Orbit (LEO), and Pegasus XL costs over $100,000.

By using Martian regolith, the loose bedrock of the red planet, or other space-sourceable materials, like ice, NASA hopes to be able to dramatically cut down this price.

Phases of NASA’s Habitat Challenge

NASA Habitat Challenge is divided into three phases, with 18 teams taking part.

In phase 1 of the challenge, the Design Competition (2015), teams created and presented architectural details of their planned structures.

For Phase 2, the Structural Member Competition, completed in 2017, NASA partnered with the Bradley University of Peroria, Illinois. This phase required that the teams build elements of the structures either from a combination of indigenous materials and recyclables, or indigenous materials alone. Phase 2 had a prize purse of $1.1 million and served as a qualifier for the next phase.

The competition is now in its final phase: the On-Site Habitat Competition. There are three construction levels and two virtual levels. At the virtual levels, teams must use Building Information Modelling (BIM) software to design the habitats. Finally, at the construction levels, the teams must be prepared to autonomously 3D print the elements of the habitat.

Phase 3 winners of NASA’s 3D Printed Habitat Centennial Challenge

The $100,000 prize purse of Virtual Modeling Stage (Phase 3) was distributed among the top five teams.

– Team Zopherus from Rogers, Arkansas, is the winner of the first prize $20,957.95.

– AI. a global architecture practice, with its skunkworks SpaceFactory, New York, won the second prize, $20,957.24.

– Kahn-Yates, Mississippi, a team of design and architecture firm, the Kahn Companies, occupied the 3rd place and was awarded $20,622.74.

– The fourth place ($19,580.97) was occupied by SEArch+/Apis Cor of New York, known for 3D printing a building in 24 hours.

– At the fifth place was the Northwestern University of Evanston, Illinois winning $17,881.10.

Mars habitats

Team Zopherus designed a walking lander robot inspired by spiders. The lander arrives at a certain location and builds itself using 3D printing, sourcing local raw material for construction, including concrete made from Martian ice, calcium oxide, and Martian aggregate.

A funky multi-storied 3D printed house, that looks like a set-piece from a 60s space movie, was SEArch+/Apis Cor’s contribution to the project.

The construction has 9 steps. It begins with the deployment of payload. In the fifth step the foundations of the structure are 3D printed, in the eighth step the autonomous robot 3D prints regolith shell, and in the ninth step plants are grown and the structure is ready for the arrival of the crew.

Mining space for materials

Other space organizations and companies are also looking towards 3D printing technology to provide solutions in space.

The European Space Agency (ESA), headquartered in Paris, France, collaborated with Fotec, an R&D department at the University of Applied Science, Austria, and 3D printed a miniature igloo from a composite material containing “Mars dust”.

Mining resources from Moon and Mars is the space industry’s next ambition. The Moon Express (California), a company taking part in Google Lunar XPRIZE wants to go beyond winning the prize and find ways to mine the Moon for its resources.

For more news on the mission to Mars, subscribe to our newsletter, or follow us on Facebook and Twitter. For jobs in the 3D printing industry visit our job site.

Featured image shows the virtual design of AI. SpaceFactory’s Mars habitat named “MASHA”. Photo via NASA