Dr. Advenit Makaya is an Advanced Manufacturing Engineer in Materials and Processes at the European Space Agency (ESA).

I caught up with Dr. Makaya in Barcelona to find out more.

In his role at the ESA’s European Space Research and Technology Centre (ESTEC) in the Netherlands, Dr. Makaya coordinates In-situ Resource Utilisation (ISRU) for the agency’s 3D printed Lunar and Martian regolith project. As such he believes greatly in the human potential to colonize Mars, and has a good idea how long it will be before we get there.

Before joining the ESA in 2014, Dr. Makaya worked in stress analysis for components and materials at Roll-Royce in the UK. His academic research includes a PhD from the Royal Institute of Technology in Stockholm, and postdoc studies at Japan’s national research institute.

The private space race to Mars

In the second great space race for Mars, competition is now fiercer than ever due to the growth of independent exploration companies. “I think it’s a driving force for the space industry,” says Dr. Makaya discussing Elon Musk’s private SpaceX program, “because they are bold enough to try new stuff,”

“It is true that they are redefining the space industry on that scale.”

To this, however, Dr. Makaya adds that there still pros and cons about such projects. Though SpaceX may drive innovation and encourage traditional engineers to think differently, Dr. Makaya adds, “we, especially as an agency are concerned about certification, about reliability,”

“We want to take the time to grow new solutions, new technologies, to be mature enough to be considered reliable. We are kind of on the side of encouraging innovation, but in a controlled way.”

When will we 3D printing on Mars?

Though Dr. Makaya expects that he may yet see human footprints on Mars in his lifetime, he explains “In the distant future, I’m not as optimistic as Elon Musk […] But a foot on Mars, I think so, I hope so […] having a colony on Mars, honestly no.” This is due in part to the many challenges posed by fabrication on The Red Planet.

First of all, there is 3D printing in a vacuum, and also accounting for the extreme temperature fluctuations on other planets. Fortunately, these conditions are fairly easy to replicate on Earth, but they still aren’t an ideal manufacturing environment.

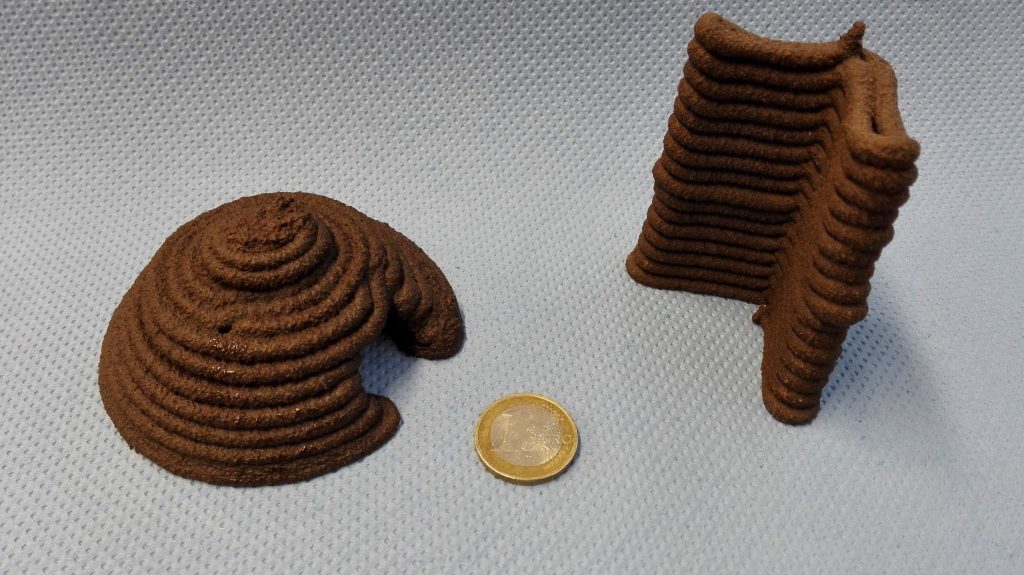

More challenging, is an ability to 3D print in micro-gravity conditions. As Made In Space has proven, FFF 3D printers can be used effectively in space using high grade polymers such as PEEK. ESA researchers are also investigating a method using mirrors to concentrate energy from the sun. This method, in contrast to the “microwave” method, uses solar light with a solar furnace to sinter materials, rather than microwaves of heat.

In both instances gas bubbles trapped in the material are affected differently by microgravity, and can cause structural weaknesses in a finished part.

And finally, the dust itself. Not only is regolith an abrasive material, it also sticks everywhere. This is especially a concern when on Mars, as the atmosphere can create sandstorms, and any hardware in place must be able to withstand such force.

The role of Big Data

On a personal level, Dr. Makaya also believes that Big Data will play an important role in the future of 3D printing. “I think the next phase of 3D printing is to use the capabilities of Big Data and the Internet of Things to optimize the processes.” Here he references the rise of smart factory concepts and autonomous technology, envisioning a future of “intelligent machines which can adapt to the parameters by just looking at the material effects.” This of course would also be important to machines that can build habitats on Mars or the Moon.

In closing, Dr. Makaya adds, “One thing about printing on a planet, is you are not going to have an [astronaut] standing next to machine pressing the buttons […] Most probably we will send the machines before we send the humans so they can print the ground for us.”

If you want to see what NASA’s Chief Technologist has to say about 3D printing in space, then watch this video from our Editor-in-chief.

For more exclusive content from 3D Printing Industry, subscribe to our free newsletter, follow us on Twitter and like us on Facebook.

Looking for a new job opportunity? Register on our 3D printing jobs site here.

Featured image shows a floating ESA astronaut patch containing flags of all the member states in the International Space Station’s cupola window. Photo via ESA/NASA