Airwolf 3D, a 3D printer manufacturer headquartered in Fountain Valley, California has announced the release of its latest 3D printer, the EVO 22 large 3D printer. This 3D printer, also known as an additive manufacturing center, serves as a large-scale alternative to its current EVO printer.

“We’re often asked what makes our machines different,” said Erick Wolf, CEO and Co-Founder of Airwolf 3D. “Other machines in [our] price class simply don’t offer the same level of performance and quality.”

“Whether it is because their beds and hot ends fail to reach and sustain the temperatures required for pure, engineering-grade filament or they cut corners and use flimsy construction that, again, can not support advanced industrial desktop manufacturing.”

The new EVO

Founded in 2012, Airwolf 3D’s goal was to design easy-to-use 3D printers that are both accurate and fast while being suitable for engineers, hobbyists, and students alike. Its latest 3D printer, the EVO 22, is a larger alternative to the previous EVO Additive Manufacturing Center which made its debut earlier this year at CES.

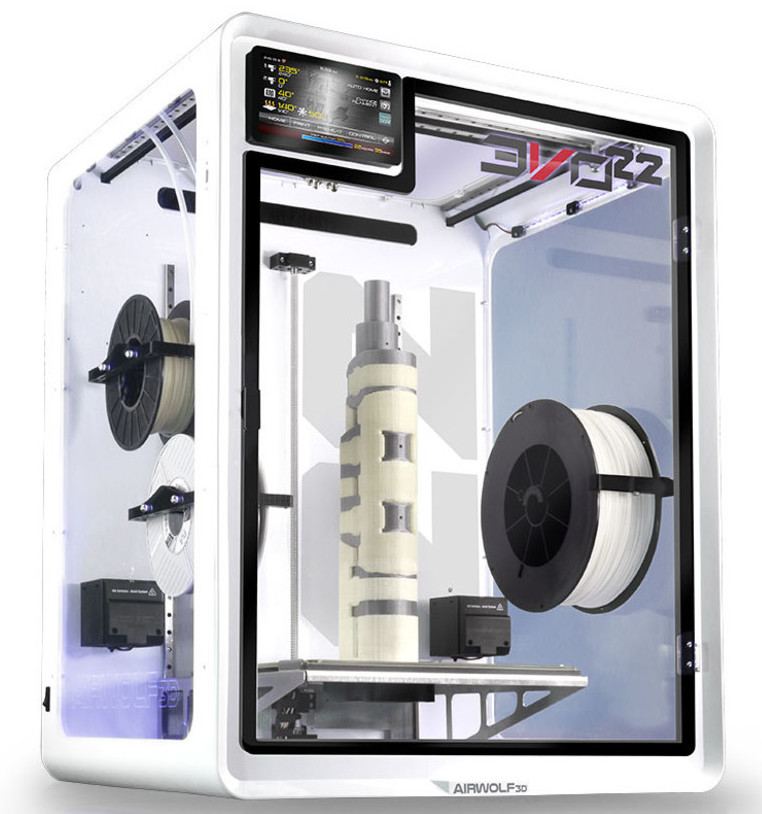

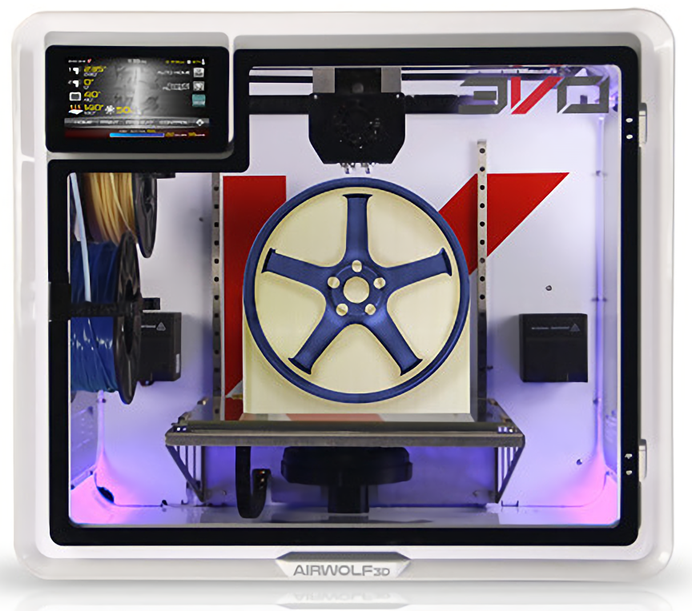

The new metal 3D printer stands at 22.75-inches in height making it almost a foot taller than the previous model. This allows for the user to print out larger parts than the standard Airwolf 3D EVO.

The printer is optimized for large-part production and can manufacture high quality, real-scale, end-use parts in over 40 different materials. Central to the EVO 22’s ability to print large parts successfully is its proprietary Tri-Heat Build Environment.

Comprised of two built-in chamber heaters and a high-temperature print bed, rated for 160 degrees Celsius, the Tri-Heat Build Environment gives users greater control over the machine’s internal ambient temperature, allowing them to create the ideal thermal environment for producing large parts.

It also comes oversized air filtration system works to actively contain ultrafine particle and volatile organic compound emissions during the desktop manufacturing process. This allows for the printer to be used in smaller, less ventilated spaces.

Like its predecessor, the new EVO 22 is outfitted with a cartridge-style planetary extruder assembly and a three-bolt-reinforced QuickChange hot end for faster, more precise extrusion of materials.

Bigger and better.

According to Jazmin Casing of Airwolf 3D, the theme of “printing big” has been central to the company’s success.

Back in 2013, it released the Airwolf 3D XL which was, at the time, the largest ABS build platform in its class. That was followed by the 2015 AXIOM Dual which was optimized to print larger parts in high-temperature materials like ABS and polycarbonate, followed by the larger AXIOM 20.

Then came the EVO which added FailSafe and PartSave technology to protect a project in the event of material or electricity running out, allowing for a more consumer-friendly product. Until finally, the recently announced EVO 22, which allows for even larger metal prints.

Improvements in 3D printing

Last year, Wolf gave us his thoughts on the future 3D printing in our Future of 3D Printing series. He explained:

“When 3D printing exploded into mainstream culture in 2011, many pegged their hopes on the intriguing new technology. Consumers learned a hard truth about desktop 3D printers: clogs, jams and malfunctions were common and a relatively steep learning curve was required to even get the machine to work at all. In short, the technology was awkward and premature.”

“The good news is that we have entered a new era, a period of time when we not only possess a deeper understanding of how our customers use 3D printing, but we also are innovating and improving software and hardware at a rapid pace”

Technical specifications and pricing

| Build volume | 12″ x 12″ x 22.75″(305 mm x 305 mm x 578mm) |

| Weight | 150 lbs |

| Maximum Print Speed | 100-150 mm/sec |

| Extruder Temperature (Max) | 315°C |

| Print Bed Temperature (Max) | 160°C |

| Layer Height (Min) | 40 microns |

| Calibration | Auto-Leveling |

| Materials | Over 40, incl. ABS, PC, PP, Nylons, TPE, TPU |

| Filament size | 2.85mm +/-0.10 |

| Nozzle size | 0.8 mm Heavy Duty included, 0.5 mm and 0.3 mm optional |

| Motion system | Core XY |

| Enclosed print chamber | Yes |

| Heated bed | Yes |

| Cooling fans | Dual Part Cooling, Single 60 mm Extruder |

| Display | Touchscreen 7” |

| Provided software | APEX, APEX Pro (Coming soon) |

Airwolf 3D’s EVO 22 will be priced at $11,995 (US) and is scheduled to start shipping in September 2018.

Keep up to date with all the latest 3D printing news by subscribing to our 3D Printing Industry newsletter. You can also like us on Facebook and follow us on Twitter.

Sign up and post on 3D Printing Jobs here to explore new and exciting opportunities near you.

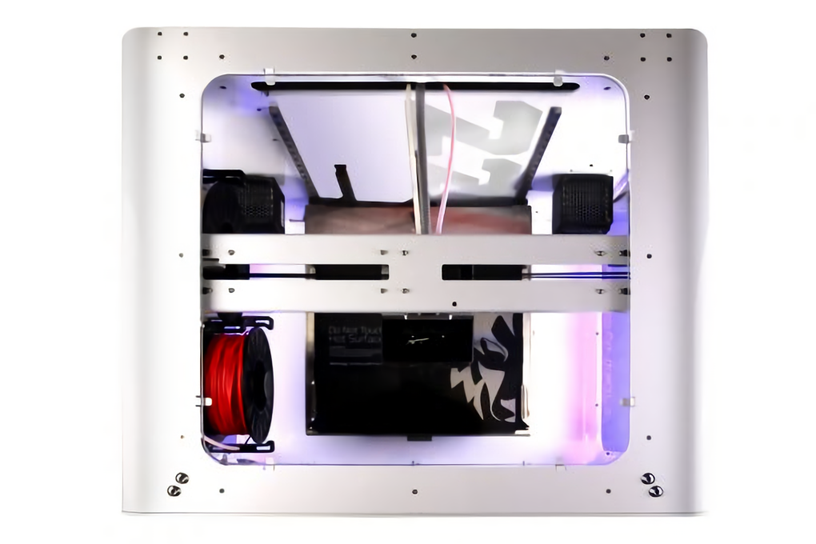

Featured image shows the EVO 22 3D Printer. Photo via Airwolf 3D.