4D printing is method of 3D printing that allows an object to transform. In many cases, 4D printing has been used as a kind of “origami effect” where a flat, 3D printed net is tuned to fold into a three-dimensional object, such as a tulip. If scaled-up, the method could even make way for self-making flat pack furniture, or easy-assemble scaffolding.

The ability to self-fold and transform gives researchers a whole new area of possibilities, particularly in the field of medicine. Instead of compensating for large implants/medical devices with incisions in the body, operations can become less invasive. And, instead of relying on blood circulation to treat a problem, drugs can work harder to target a problem.

Rutgers University–New Brunswick researchers Daehoon Han, Zhaocheng Lu, Shawn A. Chester and Howon Lee, have developed a new method of 4D printing straight out of Alice in Wonderland. Based in SLA, Rutgers’ 4D printed objects can shrink and swell on-demand.

A shrinking king

The shrinking chess king demonstrated in the Rutgers study is made from a hydrogel. Though 73% water, the material retains a solid shape.

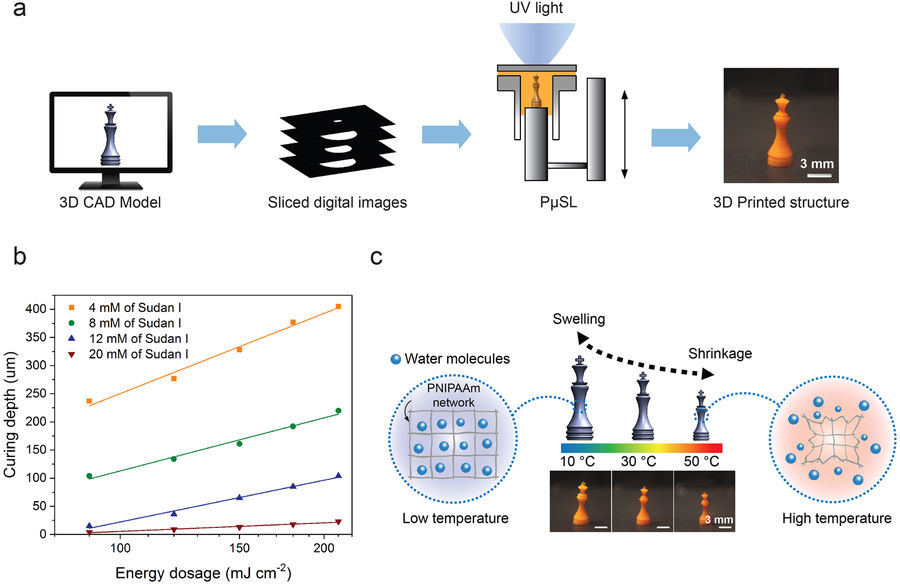

Transformation of the gel occurs in a bath of water. By gradually increasing the temperature up to 50°C, the king becomes dehydrated and shrinks. Likewise, as the temperature is decreased to around 11°C, the king swells back to its natural size.

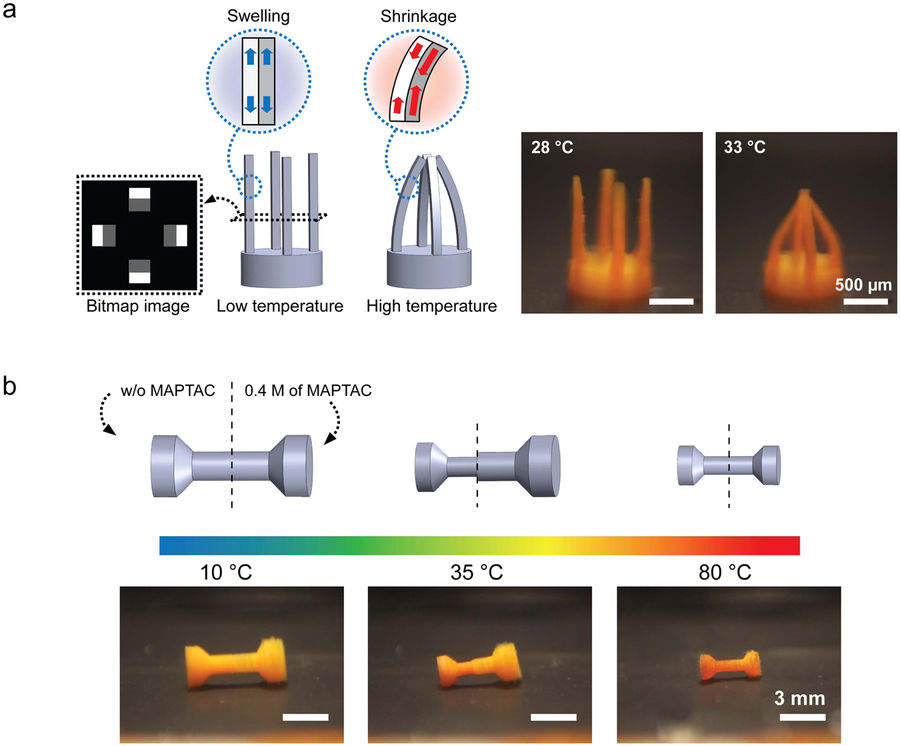

The team also demonstrated how to add this shrinking/growing principle to specific parts of an object, rather than the whole thing. For example, the prongs of the claw can shrink and grow to close, but the body holding them together stays the same.

3D microprinting process specifics

The 3D microprinter (termed the PμSL system) used in this study was custom-made by the Rutgers team. It consists of Liquid crystal on Silicone (LCoS) digital mask that exposes each layer to a different UV light outline; a projection lens; a UV LED; a linear stage; and a collimation device to control the UV beam width.

In the first step of printing, a digital 3D model was generated on CAD software and sliced into bitmap images. Each digital image was transferred to a digital mask to optically pattern ultra-violet (UV) light, which was projected on to prepared photo-curable PNIPAAm resin.

Through photo-polymerization, the patterned UV light converted the liquid resin into a solid layer. Once a layer was formed on the linear stage, it then dropped to expose the next layer.The process continued until the entire object was manufactured.

A medical shapeshifter and potential game-changer

“The full potential of this smart hydrogel has not been unleashed until now,” explains Lee, from the Rutgers School of Engineering. “We added another dimension to it, and this is the first time anybody has done it on this scale.”

The team is working on the micro-scale with this hydrogel, making objects with features ranging between 50 μm and 7 mm. The hope is that it can be used to develop new biomedical devices, like cell scaffolds, that help promote tissue growth, or even drugs with a precisely controlled released period, potentially giving patients more than one dose over time.

“If you have full control of the shape, then you can program its function,” Lee adds, “I think that’s the power of 3D printing of shape-shifting material,”

“You can apply this principle almost everywhere.”

“Micro 3D Printing of a Temperature-Responsive Hydrogel Using Projection Micro-Stereolithography” by Han, Lu, Chester and Lee is published online in the journal Scientific Reports.

Think this is award-winning research? Nominate the Rutgers team now in the 2018 3D Printing Industry Awards.

For more industry-leading research subscribe to the most widely read newsletter in the industry here, like 3D Printing Industry on Facebook and follow us on Twitter.

Featured image shows Rutgers’ shrinking chess piece. Clip via Rutgers Today