Existing in their billions and responsible for exchanging water, oxygen and carbon dioxide between blood and tissue, capillaries are at the core of the human body. As such, recreation of these vessels is considered to be a ‘Holy Grail’ for tissue engineering.

Investigating materials to provide support for vessel growth, researchers at Rice University and Baylor College of Medicine in Houston, Texas, have identified life-supporting potential in a gelatin hydrogel that can be 3D printed in reaction to light.

The research shows an ability to grow new vessels in the way they are first formed in an embryo, demonstrating a step toward successful creation of tissues that could one day be transplanted into humans.

Gelatin support

The 3D printable material used in this study is GelMA – a semi-liquid material composed of gelatin, the denatured form of collagen and most prolific protein in the human body. To this gel, the researchers add a mixture of stem cells extracted from human bone marrow and the lining of blood vessels.

For comparison, the researchers also added this cell mixture to a fibrin-based support material widely used for cell culture – but not 3D printable.

After one week of culture, researchers discover that the cells start to form tubes inside the GelMA material.

Fluorescent imaging of cells forming vessels between day 3 and 4 of culture inside GelMA support material. Clip via Biomaterials Science supplementary materials timelapse Movie 5.

At this stage the tubes in GelMA are more truncated than those in fibrin gels. However, after the 7 day mark the cells continue to grow and proliferate into more prominent vessels, proving that photocurable GelMA is a viable option for supporting the growth of capillaries.

Discoveries and challenges

By discovering the viability of GelMA as a material supportive of a mixture of cells, the researchers believe that the study could be beneficial to the development of vessel-like structures that require different densities of capillaries. 3D printing will also facilitate this development as it enables researchers to design a supporting web of material that match the map of those in the body.

The main barrier, as stipulated by researchers’ conclusions, is that vat polymerization techniques have difficulty achieving a tubular diameter as small as capillaries.

Achieving 3D printing invisible to the naked eye

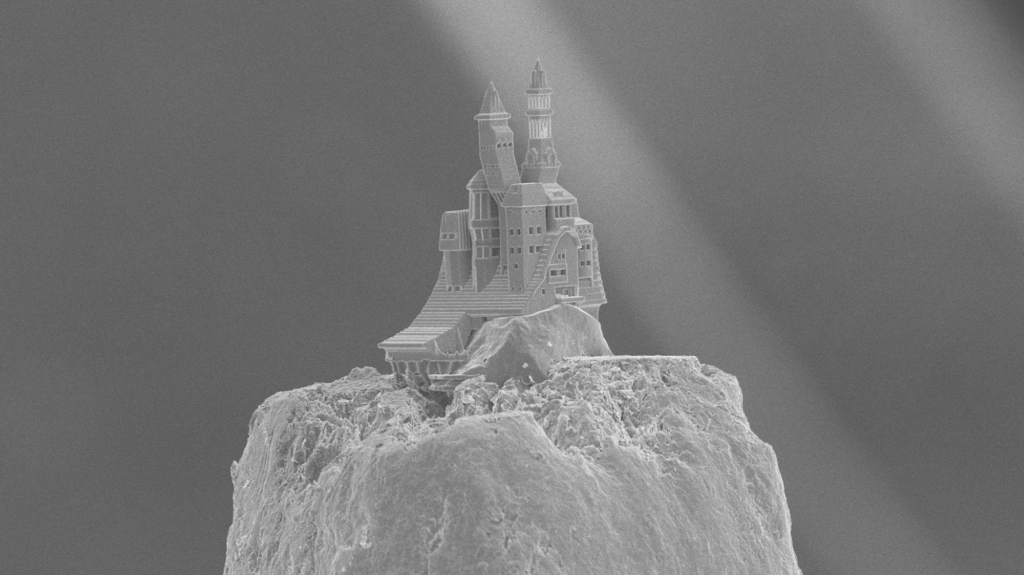

3D printing on sub-micron scale has previously been achieved by TU Wien using multiphoton lithography. Taking SLA-type 3D printing to a microscopic degrees, the TU Wien team created a castle smaller than the tip of a pencil. Also working on the nano-scale, a recent paper published in Small looks at the use of lasers to 3D print a biocompatible hydrogel.

The paper, Tubulogenesis of co-cultured human iPS-derived endothelial cells and human mesenchymal stem cells in fibrin and gelatin methacrylate gel, discussed in this article is published online in the journal Biomaterials Science. It is co-authored by G. A. Calderon, P. Thai, B. Grigoryan, S. M. Gibson, M. E. Dickinson and J. S. Miller from both Rice University and the Baylor College of Medicine.

To stay updated with all the latest 3D printing news and research, subscribe to the most widely read newsletter in the 3D printing industry, follow us on twitter and like us on Facebook.

Featured image: Stem cells forming capillaries between days 3 and 4 of the Rice University study. Screenshot via Biomaterials Science supplementary materials Movie 5.