What happens when you combine 3D printing, donuts and iron?

Researchers from the University of St. Thomas, Minnesota have used an FDM 3D printer to create a more efficient transformer core.

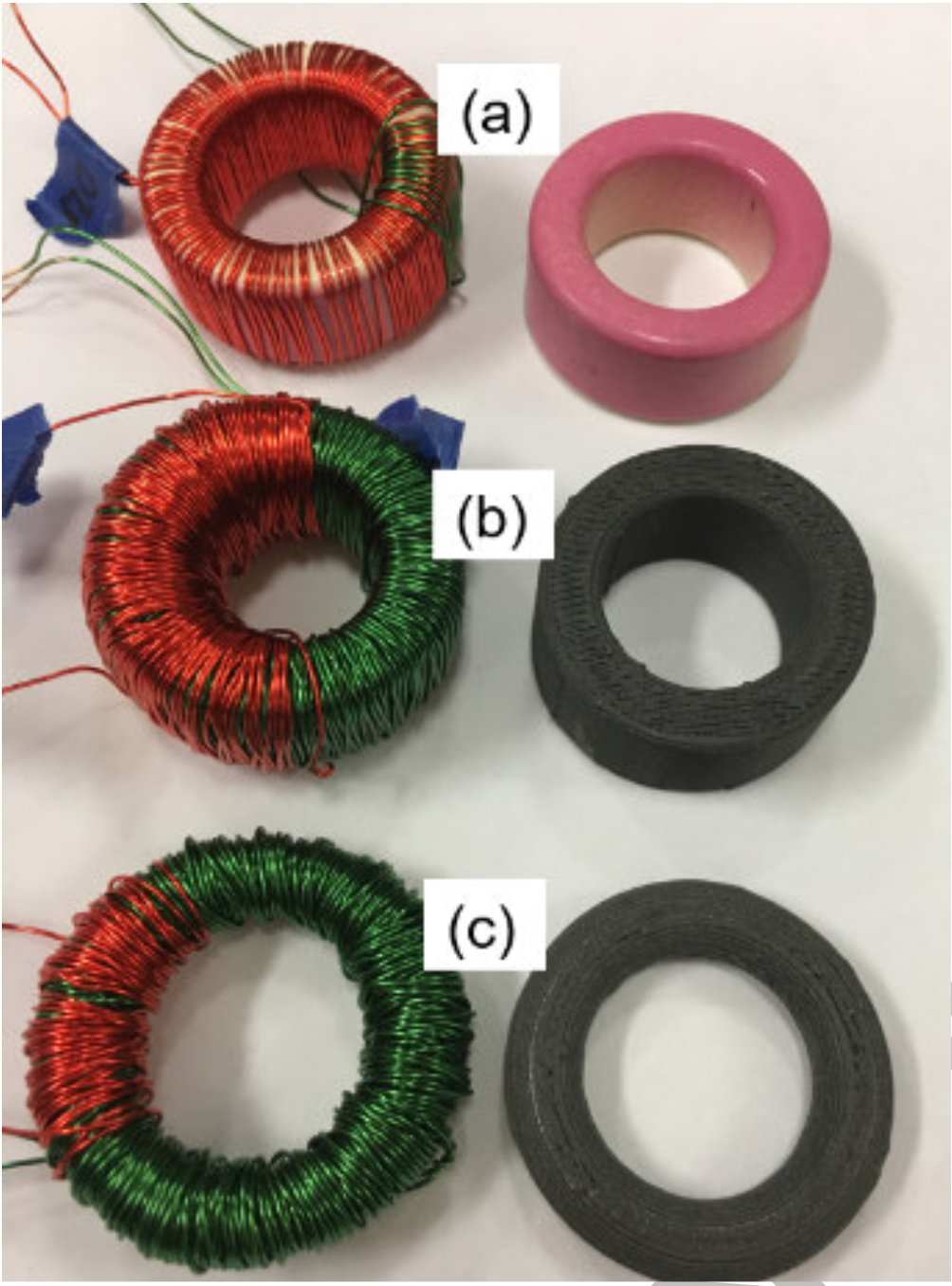

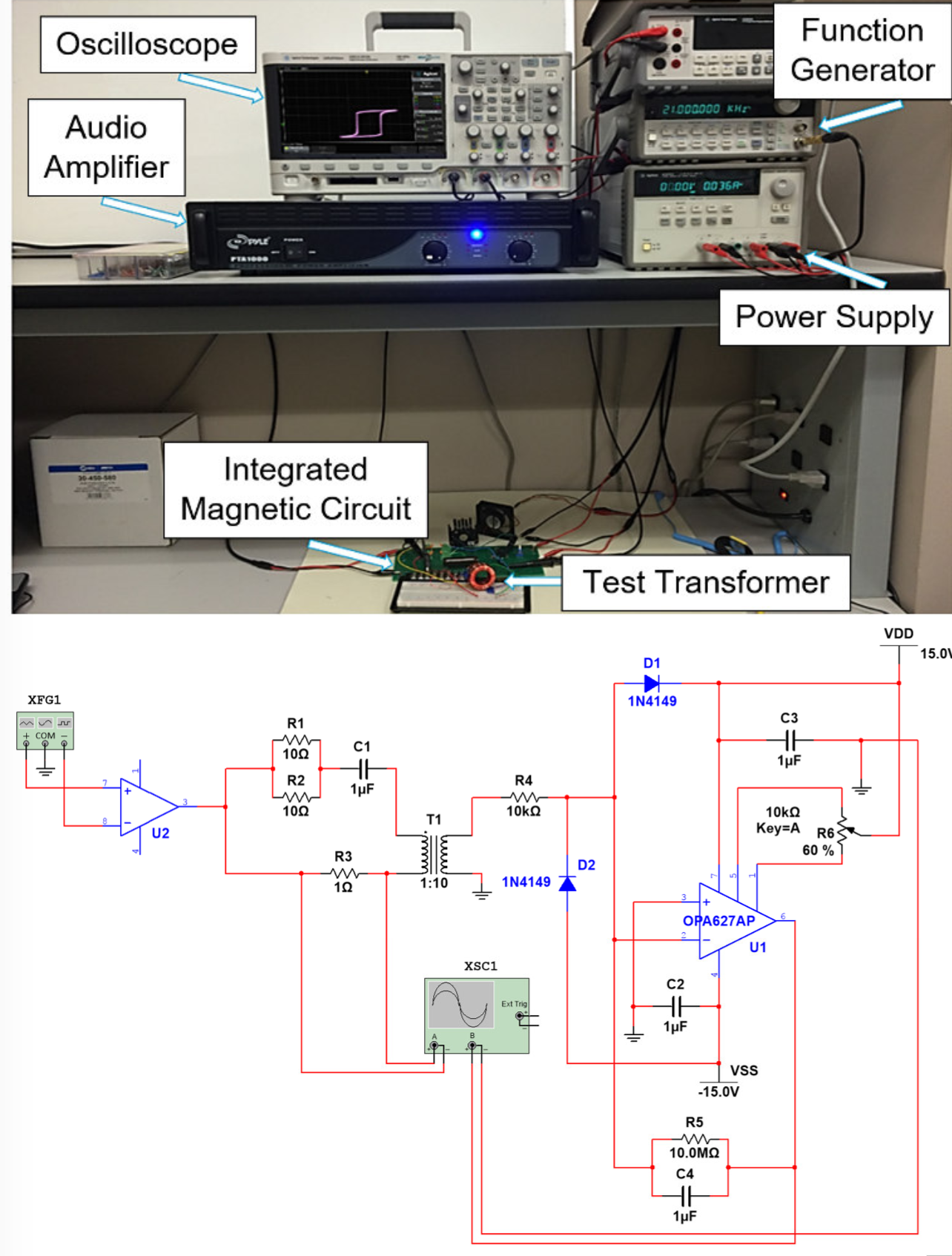

Transformers are used in the transfer of electrical energy, increasing or decreasing the levels of voltage and typically come in the form of a magnetic core wrapped in two layers of electrically conductive wire.

The researchers aimed to explore the increased possibilities of 3D printing to create complex shapes of the magnetic cores and improve their efficiency. Additionally, the researchers believe by developing the manufacturing processes of transformer cores they could also reduce costs.

Transformer cores

According to the study, “a donut-like toroidal geometry theoretically makes the most efficient transformer due to its ability to maximize the enclosed magnetic flux.”

However, despite this, transformers are so often in the form of less efficient shapes “due to restrictive manufacturing costs.” Combatting this the researchers employed 3D printing for its ease of creating complex shapes.

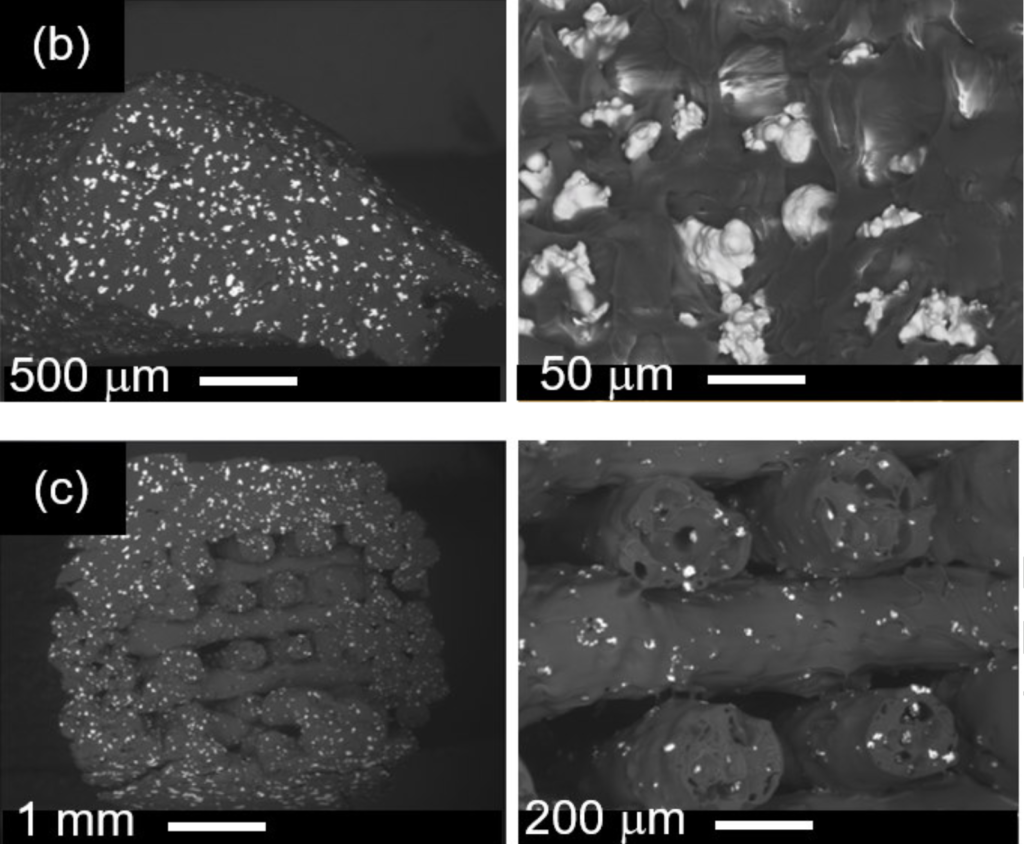

The research team used a PLA filament which was infused with iron. Namely Proto-Pasta’s ‘Rustable Magnetic Iron’ filament (1.75 mm diameter) and 3D printed the toroidal shapes on a gCreate – gMax 3D printer.

The filament was extruded at 210 degrees celsius and the composite PLA material was used to provide the element of magnetism. Michigan researchers have recently evaluated the thermal properties of such composite filaments to provide quantitive information for future research such as this one.

Optimizing magnetism

The research paper concludes that the 3D printed core was indeed efficient for its shape. However there were a number of factors which could optimize its magnetism. In particular, the researchers explain the highest fill factors must be used and higher iron content would be beneficial.

As the researchers explain,

the most effective 3D printed transformer core requires a high fill factor along with a high concentration of magnetic particulate.

The paper ‘3D printed magnetic polymer composite transformers’ is published in the Journal of Magnetism and Magnetic Materials.

For all the latest 3D printing news, subscribe to the most widely read newsletter in the 3D printing industry, follow us on twitter and like us on Facebook.

Featured image shows a previous pairing of a donut shaped object and Iron(man).