The 3D bio-printing market has seen significant activity in 2017. Several companies are preparing 3D printers for launch and we have frequently reported on academic studies in this area.

A number of 3D printing methods including extrusion, inkjet and patterning with lasers have been used to create scaffolds or structures necessary for cell growth.

However, the use of high-powered lasers to pattern micro/nanoscale objects has drawbacks. In particular, the substantial energy required to move material or objects means that high throughput of material is not possible.

Improving control over the micro structure

Now a team at the National University of Singapore have announced another technique to engineer living tissue. The process is described in the nanotechnology journal, Small.

In the paper “Effective Light Directed Assembly of Building Blocks with Microscale Control” a method for improving control over the micro structure with light-directed assembly is described.

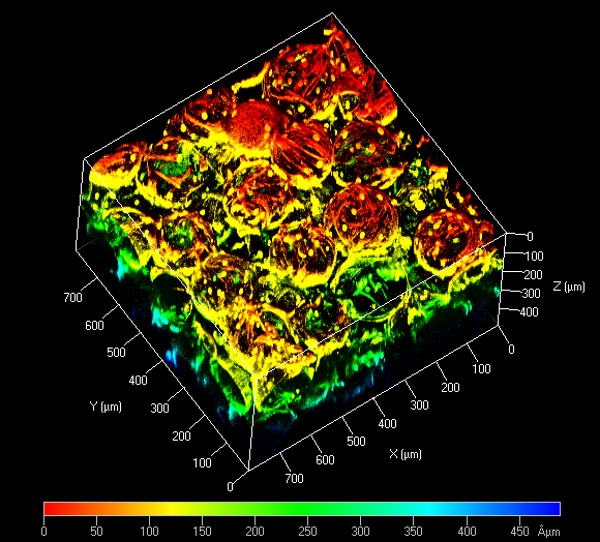

The researchers believe their method could have applications for bioprinting, tissue engineering, and advanced manufacturing. Working with microfluidic-fabricated monodispersed biocompatible microparticles the scientists were able to fabricate a structure.

The control with microscale precision is approached by changing the size of the laser light spot. After crosslinking assembly of building blocks, a novel soft material with wanted pattern is approached.

Gold nano-rods are the key

The specific difference in this approach is that it uses gold nano-rods (GNRs). The GNRs serve to harness the energy from the laser, and in doing so mean a lower power near-infrared (NIR) laser can be used – yet with greater precision.

Experiments were conducted to test the effectiveness of the bioprinting method using a hydrogel. The results showed that working with the NIR bioprinter it was possible to “construct scaffold-free tissues with desired structures.”

The paper was authored by Dinh Ngoc Duy, Rongcong Luo, Maria Tankeh Asuncion Christine, Weikang Nicholas Lin, Wei-Chuan Shih, James Cho-Hong Goh, and Chia-Hung Chen- PhD and can be read here.

For more insights into the future of 3D printing, sign up to our newsletter and follow our active social media channels.