3D Printing Industry reviews recent real world examples of 3D bioprinting and additive manufacturing methods in medicine.

The use of 3D printing for surgical planning took another step forward recently, we look at the use of 3D printing for surgical planning by 3D Systems. We also see how 3D printed bone matter and cartilage for regenerative medicine research is progressing. And finally, we get to the heart of discoveries with 3D printed vascular tissue, returning to China’s macaque monkeys who received effective implant of a 3D printed vein.

Our readers may also be interested in the upcoming 3D Bioprinting Conference. 3D Printing Industry will be reporting from the event in Maastricht later this month.

Successful surgical planning

Patient-specific 3D printed models of anatomy a valuable application of 3D printing, saving valuable time in operating rooms and improving patient outcomes.

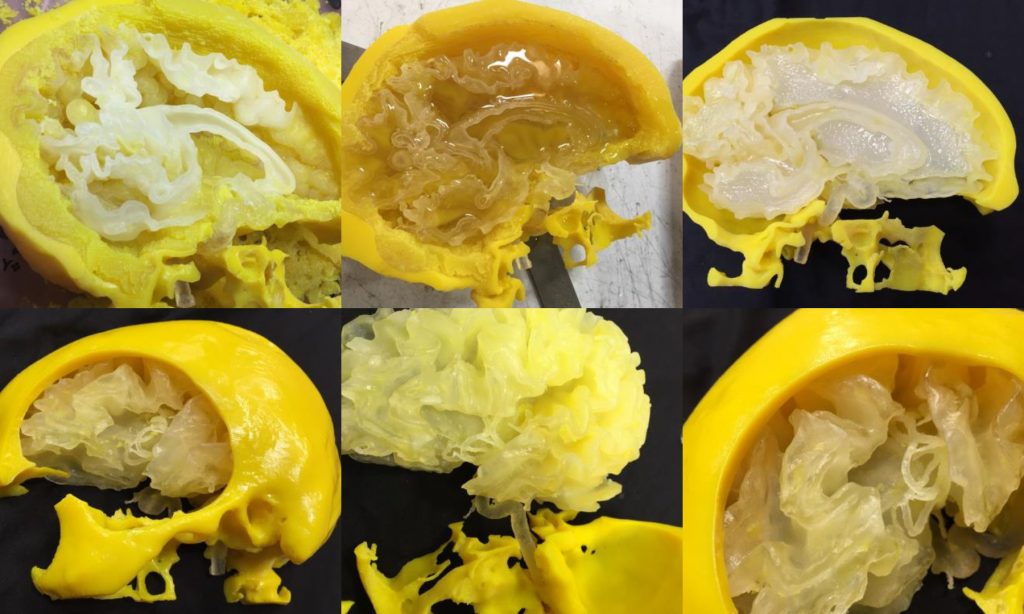

Stratasys Direct Manufacturing have created 3D printed brain models. California-based Spinal Elements are producing surgical guides for spine surgery. And a number of start-ups have been quick enter the growing market, for example in Singapore’s Supercraft3D who have acquired $1m for the purpose.

In 2016, a remarkable surgery 27-hour surgery was made possible by 3D printing. The surgery was performed on conjoined twins Jadon and Anias McDonald with the help of additive manufacturing from 3D Systems.

Although not yet commercialized, further advances in medicine are envisioned as an application for 3D Systems’ Figure 4 modules. 3D Printing Industry editor-in-chief Michael Petch recently visited the 3D Systems Healthcare Technology facility in Colorado where he spoke with the company’s CEO and senior staff.

As explained in Michael Petch’s interview with 3D Systems’ Metals and Healthcare General Manger Kevin P. McAlea says,

If you combine Figure 4 with a biocompatible material […] you could set up a localized surgical planning unit. For example in a hospital. I do see this as a long term trend.

Tissue engineering v2.0 and the bones of 3D bioprinting

Professor Daniel A. Grand of the Feinstein Institute for Medical Research, New York, terms regenerative medicine as ’tissue engineering V2.0′. Grant’s rheumatology review for Nature, examines how 3D bioprinting is taking orthopaedic treatment to the next level, particularly through the fabrication of bone cartilage.

For fixing bone fractures, 3D printable inks are in development on an international scale. Some bioinks are silk based, while others incorporate ceramics.

Northwestern University in Illinois have 3D printed calcium-plastic bones with hyperelastic qualities. The bones perform well in mechanical tests, and show promising results for biocompatibility.

A combination of 3D bioprinting and sintering is described one recent academic paper. Three-dimensional printing of porous load-bearing bioceramic scaffolds, reports the successful fabrication of 3D-printed bioceramic structures that match the properties of cortical bone.

Tobias Zehnder is one researcher speaking at the 3D Bioprinting Conference, Maastricht on the topic ‘Biofabrication of hard and soft matrix for bone tissue regeneration’. It will be interesting to see how Zehnder’s methods at the University of Erlangen-Nuremberg compare to this general overview of the technology’s capabilities.

The 3D printed heart

In late 2016, the Chinese National High Tech Research and Development Program (also known as the 863 Program) successfully implanted 3D printed vein-tissue into a live Rhesus Macaque monkey. It is the first step in pre-clinical trials that are hoped to eventually make it into humans.

CT imaging of the 3D printed blood vessel beating with blood flow inside a monkey. Image via: CCTV+ on Youtube

Researchers at Northeastern Univeristy, Massachusettes, and Georgia Tech have also developed their own unique methods for 3D printing blood vessels. Biotechnology company Celprogen even show evidence of a miniature 3D printed heart that beats when filled with blood.

Still, the fact remains that vascular tissue is made from multiple types of cells, and so faithful reconstruction of the tissue may only be possible through a combination of materials and methods.

In an article, titled From Microscale Devices to 3D Printing: Advances in Fabrication of 3D Cardiovascular Tissues published in Circulation Research 2017, authors Anton V. Borovjagin, Brenda M. Ogle, Joel L. Berry, Jianyi Zhang suggest that 3D biofabrication of a complete heart may be the most logical approach. This method would be in place of the modular approach currently being explored in research, as the authors also outline how inadequate a synthetic patch can be for such a complex organ.

Capable of replicating the heart’s reaction to substances, Harvard’s 3D printed heart-on-a-chip module and other lab-on-a-chip research is optimistic of a future without animal testing. Commercial validation for work with a similar purpose was seen in 2016 when L’Oreal entered into a contract with Organovo, again to supply biomaterial for testing. Organovo’s CEO believes the market for 3D bioprinting is valued at $10 billion.

Gif shows bioprinting of the heart-on-a-chip. Clip via: Harvard John A. Paulson School of Engineering and Applied Sciences on YouTube.

Yan Yan Shery Huang of Cambridge University is another speaker at the 3D Bioprinting Conference in Maastricht. Her research group, ‘Biointerface’ is concerned with organ-on-a-chip technologies and 3D bioprinting through electric manipulation. Her research is part of the University’s Cancer Research UK center. 3D Printing Industry are looking forward to a first-hand account of how 3D biofabrication and lab-on-a-chip technologies have a direct impact on patients’ health.

To stay up to date with 3D Printing Industry’s coverage of the 3D Bioprinting Conference in Maastricht, you can find us on Facebook and Twitter, or sign up to our newsletter here.

All of the research developments and 3D printing technologies mentioned in this article are eligible for nomination the first annual 3D Printing Industry Awards 2017. Submit your nominations here.