As seen last month in bone fractures fixed by 3D bio-printed silk, silk has great potential as a 3D printed bio-material. The trouble is when it comes to 3D printing anything less solid than, say, a surgical plate, silk as 3D printer ink is incredibly difficult to work with. Freeze drying is a key part of the bio-printing process as living stem cells do not live as long in higher temperatures, but silk protein is slow to freeze. A collaborative paper by researchers from the Department of Materials Science and Engineering and the Department of Mechanical and Aerospace Engineering at the University of Florida, has found a method of treating silk protein so that it can be 3D printed and freeze-dried for tissue engineering.

Horseradish is the magic ingredient

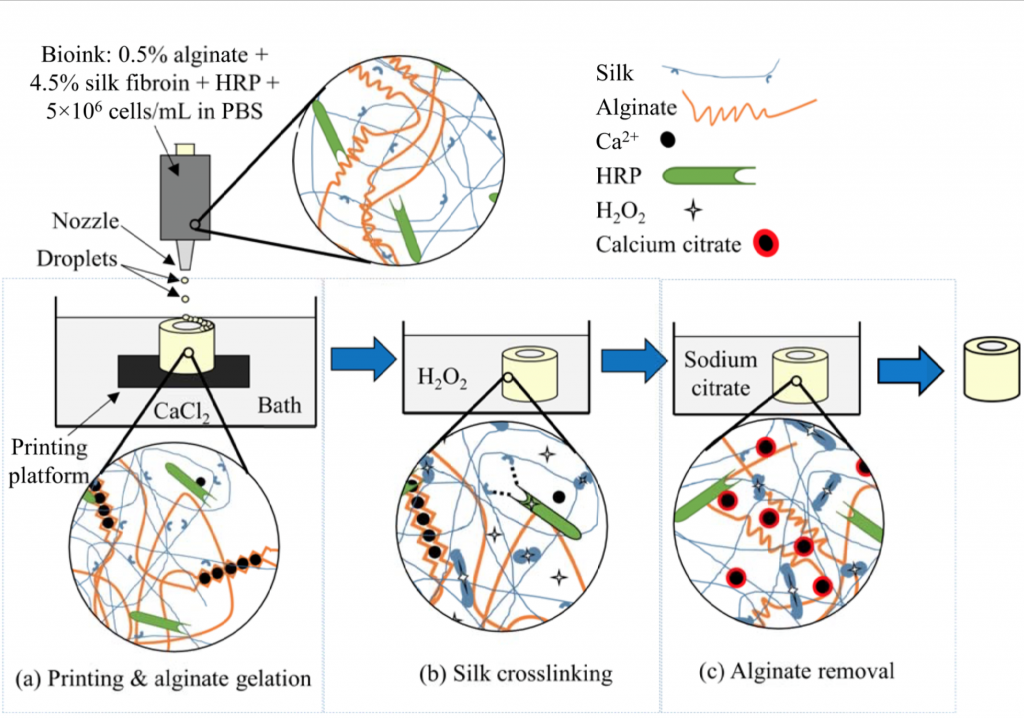

The research promotes a 2-part process that sees an alginate, a molecule extracted from the cell walls of brown algae, added to the silk protein to speed up the freezing process. This mix of alginate, and silk protein is printed using droplet based 3D inkjet printing. In the second stage horseradish peroxidase (HRP), an enzyme found in the roots of horseradish, is 3D printed into the mix to link the silk protein to tyrosine residues which act as the on or off switches in the formation of cells. After this, the alginate is removed, leaving a defined silk protein structure for cell culture.

3D printing veins to speed up healing

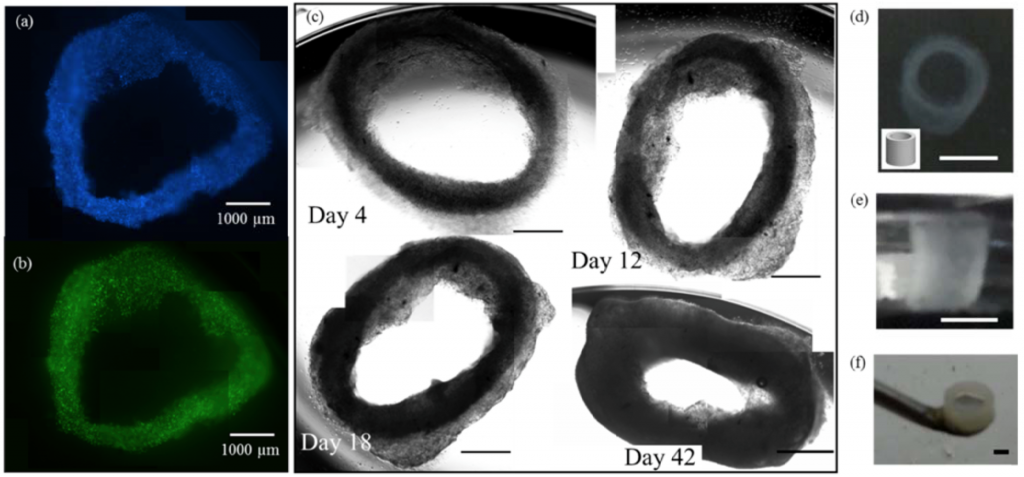

To test the process, researchers printed a tubular structure like a section of a vein. The structure was observed intact after 5 weeks, and enabled rapid multiplication, spreading and growing of fibroblast cells which are vital for healing wounds. After 6 weeks in culture, the tubes were capable of supporting their own weight in air.

Why is it necessary for cells that last so long?

In tissue engineering, embryonic stem cells can take months to form certain types of cells. Though the science is not at the ‘baby-growing’ stage yet, you can take pregnancy as an example and that typically lasts 9 months.

By engineering a silk protein ink, the team at the University of Florida hope to use it in the culture of different types of cells, and the further development of blood vessels.

This research was published by ACS Biomaterial Science & Engineering on 4th November 2016, and was supported in part by the US National Science Foundation. As previously reported by 3DPI, 3D bio-printing is forecast as a $3 billion industry.

Featured image is an digitally rendered x-ray of a horseradish peroxidase enzyme used to help the silk protein structure. Via: Manuel Almagro Rivas