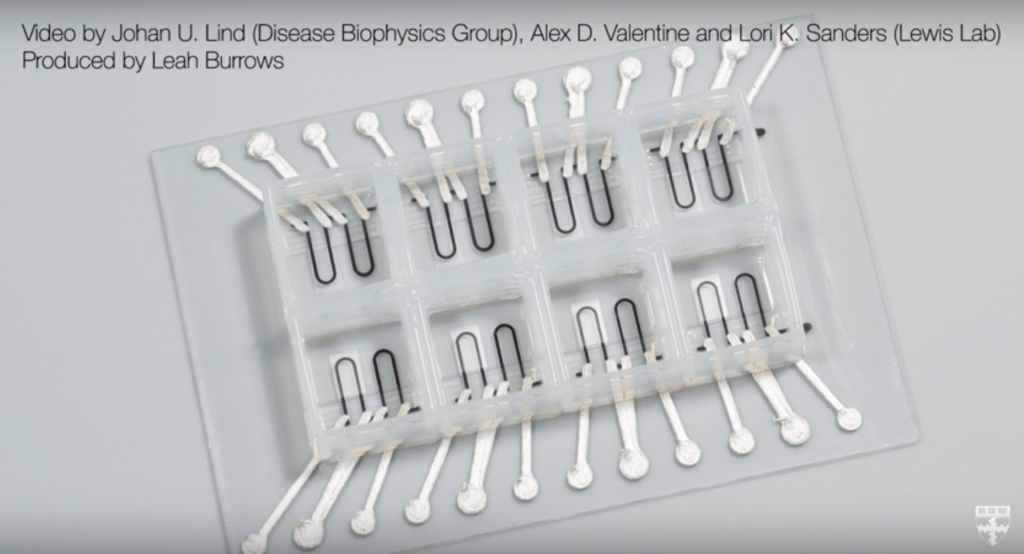

Researchers at Harvard University have managed to 3D print a functional heart on a chip that could eradicate the need for animal testing in biomedical studies. Microphysiological systems (MPS) otherwise known as organs-on-chips, have been around for some time now and researchers continue to develop new techniques using them to replicate the function of organs. For example, in studies testing new medicines or cell cultures. What’s new with this research, and especially illuminating about the study published in Nature Materials just yesterday, is that The Wyss Institute for Biologically Inspired Engineering has managed to integrate sensors into the 3D printing process and also use 3D printing to make the manufacturing process, relatively, easier.

The key development in the fabrication process is the production of 6 new 3D printable inks, including one consisting of transparent thermoplastic polyurethane, and another made from dextran, a construct of molecules related to glucose.

Though the 3D printing process, seen in the video above, is simple in its execution, developing 3D printing technology to create such a chip has not been easy. Traditionally, a microphysiological system (MPS), or organ-on-a-chip, is created in complex steps using a multi step lithography process, which is not only expensive and slow, but does not integrate sensors into the process. As Johan U. Lind, co-author of the paper, explains:

Researchers are often left working in the dark when it comes to gradual changes that occur during cardiac tissue development and maturation because there has been a lack of easy, non-invasive ways to measure the tissue functional performance.

The heart on a chip has the ability to self-contract (see above), is able to mimic the electrophysiology (think defibrillators) of a human heart, and can also be manipulated to mimic a diseased organ. With the integral sensors, the team were able to measure the beating of the heart, record the development of cardiac tissues, and the response of the heart tissue to toxic substances.

In his statement on the research, Lind went on to add:

These integrated sensors allow researchers to continuously collect data while tissues mature and improve their contractility. Similarly, they will enable studies of gradual effects of chronic exposure to toxins.

An ability to make microphysiological systems quickly and with such ease, will in turn speed up the process of future discovery. This heart is the team’s most complex chip to date. Previous research by members of the group has used a similar process to create a lung-on-a-chip, and more recently the researchers shared the news that they had successfully 3D printed the micro-structure of a kidney. Jennifer Lewis, co-author of this new research, the paper Bio-printing of 3D Convoluted Renal Proximal Tubules on Perfusable Chips and senior Professor of Biologically Inspired Engineering, had the following to say about the heart on a chip:

We are pushing the boundaries of three-dimensional printing by developing and integrating multiple functional materials within printed devices. This study is a powerful demonstration of how our platform can be used to create fully functional, instrumented chips for drug screening and disease modeling.

Featured image is a diagram showing contractile stress of the heart on a chip. Image via: Nature Materials journal