A group of researchers in Greece have proposed a new bioreactor – a vessel where tissue engineering or other biological processes can take place- with the goal of developing better bioengineered cartilage tissue growing around a 3D printed structure.

Cartilage is the thin layer of tissue on the surfaces of joints, it that shapes both the nose (septal cartilage) and ears. An advancement in the production of artificial cartilage could help a sizeable group who suffer limited mobility due to damage or wear in their joint cartilage, or have damage to other areas where cartilage plays an important role in the structure of body parts. The research group comprises multiple departments at the Aristotle University of Thessaloniki (A.U.TH.) and IESL-FORTH. The new research describes a bioreactor design that will advance the production of tissues, in particular those with high cell densities and enhanced mechanical properties leading to better quality of engineered cartilage.

Biotissues

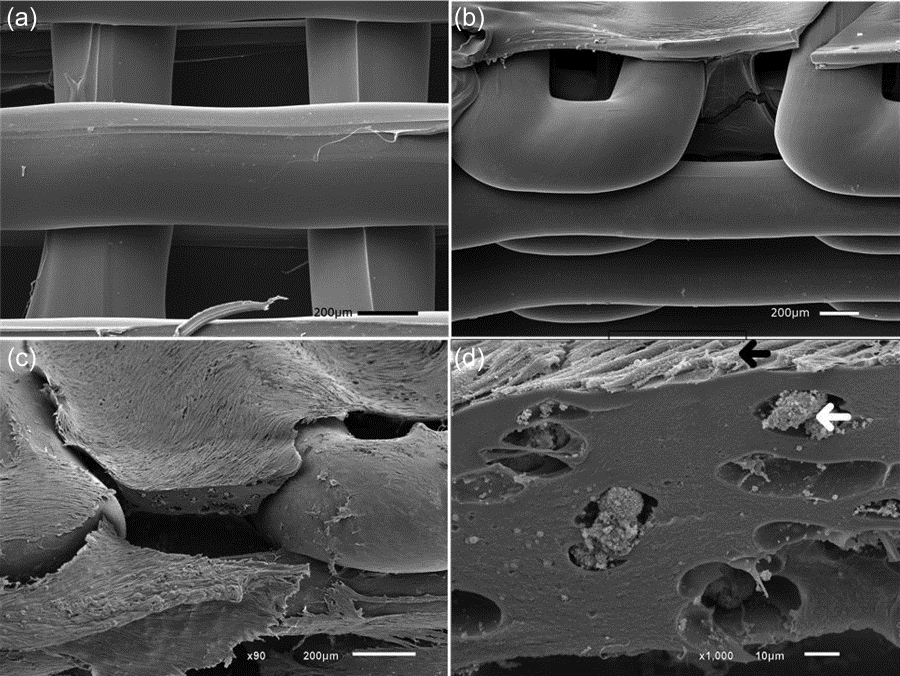

Bioengineered tissue often starts with the creation of a structure that mimics an extracellular matrix (ECM). The ECM which supports cell, and could be thought of as a web of proteins and sugars. This is the process where 3D printing is crucial since it provides the structural support where the organic cell attach and subsequently develop tissue. 3D printing allows scientists to Scientists call this the “scaffold”.

3D printing has allowed better architecture than traditional fabrication methods such as plastic injection molds since the scaffolds produced can integrate cavities within the 3D model that are not possible otherwise. In this case, the scientists used PLA to recreate a septal cartilage (nose cartilage) shaped scaffold, choosing this material since it degrades biologically as the tissue forms.

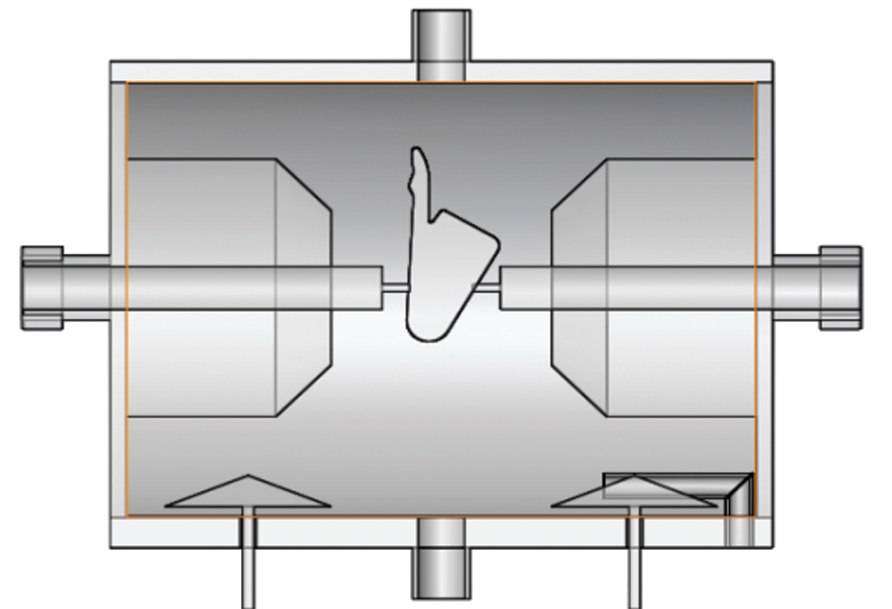

Once the 3D printed scaffold is created, it is placed inside a bioreactor, where the right conditions are set for the development of tissue. A bioreactor is basically any device or enclosure that allows a biological active environment to develop within. The Greek scientists are proposing a cylindrical chamber with a height of 12cm and a diameter of 10cm, that features a working space of 8x5x4cm where the 3D printed scaffold can be placed.

The key to the design proposed by research lead Konstantinos Theodoridis and his team, is a combination of mechanical forces that enhance better cartilage growth around the 3D printed design. Two agitator mechanisms rotating a couple of cone shaped fans will provide the internal fluid flow that acts upon the 3D printed scaffold. This produces a controlled level of shear stress in the tissue, which leads to better mechanical properties in the resulting cartilage.

Where this leads

Advances in this technology allow better tissues to be developed in shorter times. Perhaps more important to this first design proposed by the Greek scientists, is the fact that their research remarks the continual search for better bio-engineering techniques. Theodoridis and his team are continuing to experiment the combinations of the different bioreactor behaviors to produce better results.

On the practical side, generating better and larger artificial cartilage is in itself a great technological goal. Current solutions in joint degeneration include other 3D printed solutions such as joint replacement, where a whole elements made of non-organic materials such as titanium are inserted. With advances in tissue 3d printing technology, more bioengineering company investments such as the case of Organovo, the race towards the replacement of whole body parts continues down a promising path. With an appealing symmetry these next steps in the future of medical technology are coming from Greece, a country with the distinction of laying the foundations of medicine as a scientific discipline.