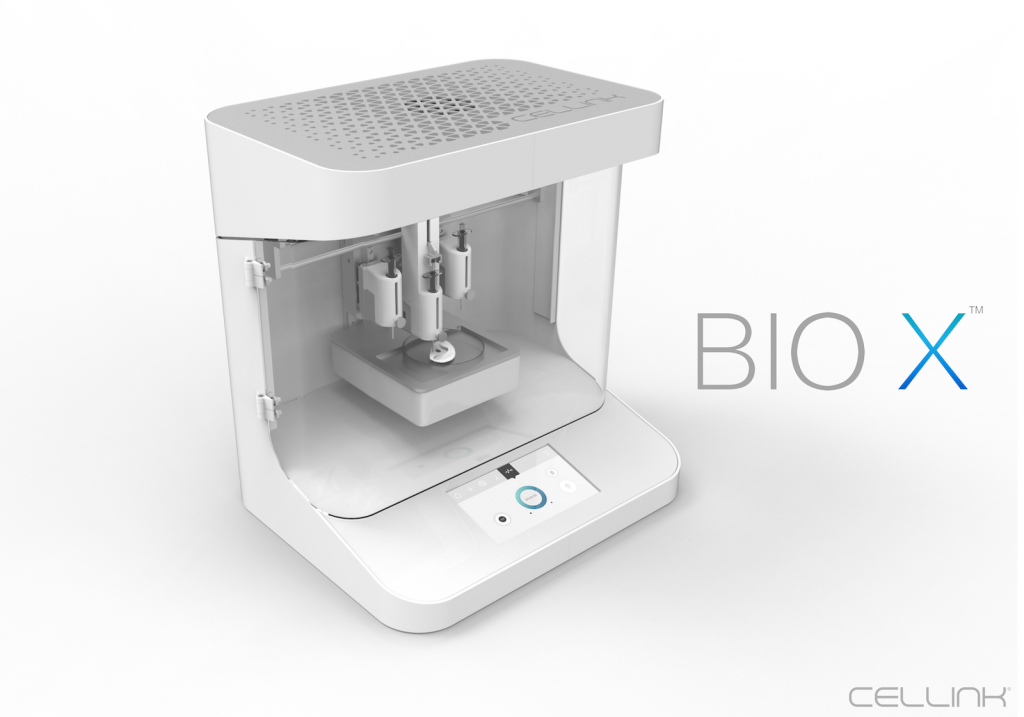

Publicly listed in November 2016, CELLINK (NASDAQ:CELLNK B), Sweden-based manufacturers of bioinks and 3D bioprinters, are releasing a third 3D printer for medical research. 3D Printing Industry spoke to Erik Gatenholm, CELLINK’s co-founder and CEO who says that the BIO X is “completely new” in comparison to their existing INKREDIBLE models, and “allows the user to bioprint a wide range of tissues in the same print.”

The power of 3 print heads

CELLINK INKREDIBLE models have two print heads capable of 3D printing hydrogels conducive to cell-growth. The new model adds another nozzle to the mix.

Not only that, but each nozzle is interchangeable, and can print at its own temperature in different materials. Heating each head individually facilitates 3D printing of live-cells, which require heat, and supporting materials like collagen that require cooled heads. Gatenholm gives an example to explain,

Cartilage cells are quite stable. They can be printed at room temperature, they can be printed in a bioink that is held at room temperature, and that’s fine. But when you start working with other cell-types, for example hepatocytes for the liver cells, they need a different environment, and they also need a different bioink.

An ability to work with multiple materials is particularly essential to producing vascular tissue. This is evident in the Chinese National High Tech Research and Development Program that successfully implanted a 3D printed blood vessel into a monkey.

CELLINK’s international reputation

INKREDIBLE 3D bioprinters are currently in use at institutions around the world including MIT, the FDA, and Australia’s Wollongong University, who has a range of scholarships available for 3D bioprinting PhD studies. This is in part due to CELLINK’s loyalty scheme which rewards research collaborators with a 50% discount on their 3D printers in return for feedback on performance.

Gatenholm is hopeful that the BIO X it will be utilized in such projects as bone patches for skulls, cancer research, and the pursuit of the 3D printed heart.

Other key features

The BIO X also has an enclosed build-chamber. This ensures the safety of samples, and a sterile environment for biomaterials.

It is compatible with all of CELLINK’s existing 3D printer materials for bones, cartilage, stem cells, skin and muscle tissue, and also adaptable for use with other bioinks.

This week’s announcement opens the BIO X for pre-order, in a materials package priced at $39,000. 3D Printing Industry are particularly interested to see the results from the beta-testing the BIO X, and research papers using the CELLINK for new discoveries.

If you would like to nominate CELLINK’s 3D bioprinters for a 3D Printing Industry Award you can do so by clicking here.

Featured image shows Team CELLINK celebrating the opening of preorders for the BIO X with a champagne breakfast at the opening of the stock exchange. Photo by: Erik Gatenholm