Professor Amir Zadpoor’s team at Delft University of Technology (TU Delft) believes that the self folding ability of 3D printed polymers could have potential for next generation medical devices. In a recent paper for the journal Materials Horizons, the team demonstrate the 3D printing’s ability to make flat nets that fold into an array of objects including a helix, pyramids and a tulip.

The aptly named “shape-shifting” research opens up an new area of innovative design that could inform the appearance and function of bone implants. “The kind of research that we do is high-risk high-gain,” explains Professor Zadpoor, “so I don’t know where we will end up five years from now.”

“What I do know though, is that the future medical implants will not look like the current ones.”

A material’s memory

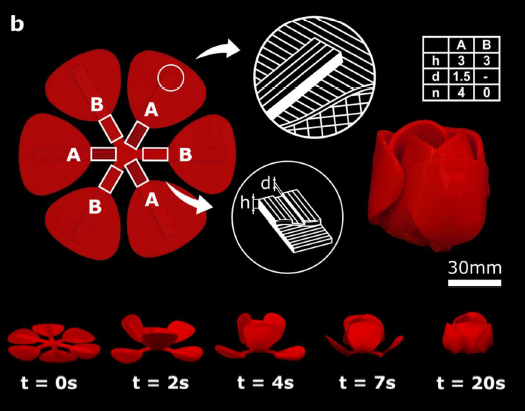

TU Delft designed objects are capable of transforming from a 2D net to a 3D shape in a matter of seconds. A tulip, for example, takes just 20 seconds to change from a flat shape into a full flower. The objects are programmed in this way by integrating grades of stress/stretch into the design. PhD researcher Teunis van Manen explains,

“The stretching is stored inside the material as a memory. When heated up, the memory is released and the material wants to go back to its original state.”

Shape-shifting in sequence

One benefit of the Zadpoor group’s research is that the objects are made for a relatively low cost on a desktop 3D printer. Professor Zadpoor explains, “At about 17 Euro’s per kilo, it’s dirt cheap. Nevertheless, we created some of the most complex shape-shifting ever reported with it.” Other structures to have been made in this way include deployable trusses, domes, lattices and Bucky balls.

The TU Delft team adds complexity to 4D printed objects by adding “sequential shape-shifting” into the design. With sequential shape-shifting, some parts of a object’s design, e.g. the outer petals of a tulip, are programmed with a delay so that they fold around other parts of an object, e.g. the center of a tulip. By staggering the folds, the researchers can make more geometrically complex objects.

Impossible medicine

Applied to medicine, sequential shape-shifting could be used to add cell-supporting textures on the inside of implants – adding a complexity otherwise impossible through FDM 3D printing.

PhD researcher Shahram Janbaz explains that the ‘instructive surfaces’ (different textures) are added to “apply certain forces to the stem cells, prompting them to develop into the cells we want them to be.”

In addition, the function can be used to add porosity to the implants encouraging the regrowth of bone cells.

The challenge ahead

Closing comments on the latest stage of research, Professor Zadpoor comments, “Shape-shifting could definitely turn many of our existing 2D worlds into 3D worlds.”

“…We have come a long way, but we still have a few major challenges ahead of us for the coming years.”

Teunis van Manen, Shahram Janbaz and Amir A. Zadpoor’s paper, Programming 2D/3D shape-shifting with hobbyist 3D printers, is available to read online in the journal Materials Horizons.

Learn more about the latest studies using 3D printing for research, subscribe, like and follow here. You can also get involved with 3D printing events near you.

Featured image shows a graphical representation of TU Delft’s self folding tulip. Image via TU Delft