Scientists at Duke and Stanford Universities have developed a device that can register a set of 2D ultrasound images as a single 3D simulation.

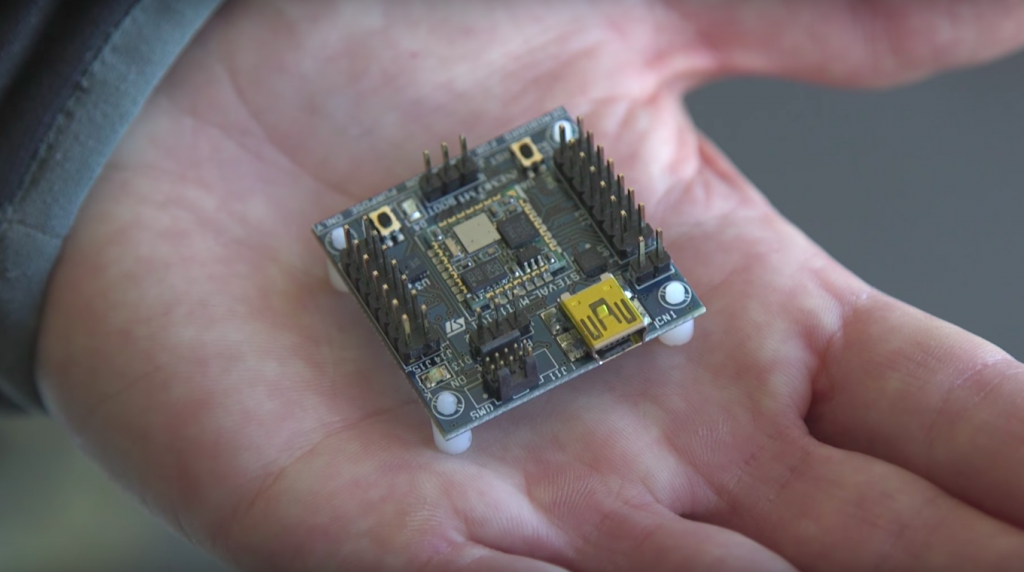

Central to the device, which was prototyped using 3D printing, is a location sensing microchip produced at the cost of $10. It was inspired by the direction tracking devices within the Nintendo Wii controller.

The scientists believe some of the most promising uses could be when CT scans or MRIs are not available, in rural areas or developing parts of the world, or even when they are too risky to be used.

The limitations of 2D ultrasound technology

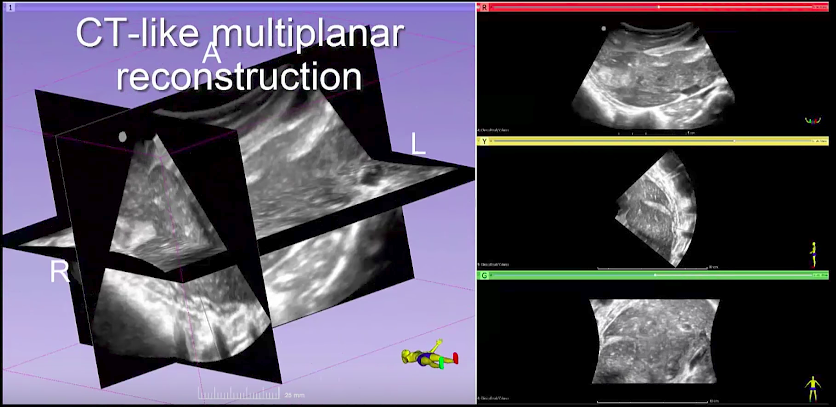

While 3D ultrasound technology is available, a machine costs as much as $250,000, five times the average cost of a standard ultrasound machine. The cost in either case will be prohibitive, but the problems with ultrasound are greater. As project leader Dr. Joshua Broder explained, “you see a visual slice of an organ, but without any context, you can make mistakes.”

In an interview with Professional Engineering Magazine, Institution of Engineering and Technology ultrasound expert Peter Bannister explained that although ultrasound noted that although ultrasound was versatile, it was also subjective. “If you suspect that there was something interesting but it’s just not in the direction the person pointed on the day with the 2D probe,” he said “that’s it, you’re never going to get that information.”

The final problem was using ultrasound on trauma patients. “Do we take them to the operating room not knowing the extent of their internal injuries or bleeding,” Broder said, “or do we risk transporting them to a CT scanner, where their condition could worsen due to a delay in care?”

To Broder, these problems could be solved at a low cost “with the added orientation and holistic context of 3D technology.”

A new dimension in ultrasound

An effective solution to these problems lay in combining position tracking software with a standard 2D ultrasound probe. Broder presented the idea to scientists Matt Morgan, Carl Herickhoff and Jeremy Dahl at Duke’s Pratt School of Engineering.

Using Duke’s 3D printing facilities, the scientists fabricated streamlined plastic holster that slips onto the ultrasound probe to hold the location sensor (with a microchip), as well as a stand to steady the probe as it gathered information. The sensor and the ultrasound probe connect via computer cables to a laptop programmed for the device.

With probe’s orientation registered, software can then seamlessly stitch hundreds of individual 2D image slices of the anatomy together in three dimensions in the correct order. Broder stated that the image quality of these contextualised 3D images was similar in quality to a CT scan or an MRI

As Bannister explained that even for small clinics in less industrialised nations, “you can still buy your ultrasound and now you can get 3D imaging for what seems to be a very small incremental cost for this kind of add-on.”

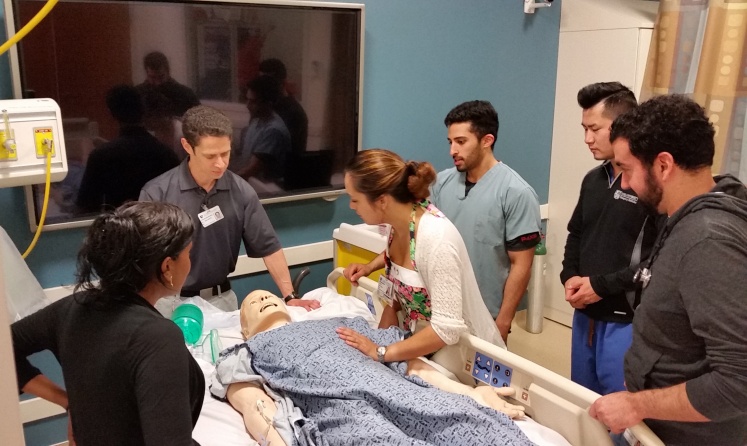

Successful applications

With a patent filed for the process, clinical trials are now being undertaken at Duke and Stanford. Broder and his colleagues also successfully collected 3-=D images of the brain of a 7-month-old with hydrocephalus, or fluid on the brain, while the baby napped.

Radiation from CT scans are not suitable for babies, making this technology effective in ante-natal care. “It’s inexpensive, it’s portable, and it’s completely safe in every patient,” said Broder. “And it’s brought to the bedside and it doesn’t interfere with patient care.”

For more on 3D printing in medicine, subscribe to our free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows the ultrasound probe with a 3D printed stand and sensor holder. Photo via Duke Health.