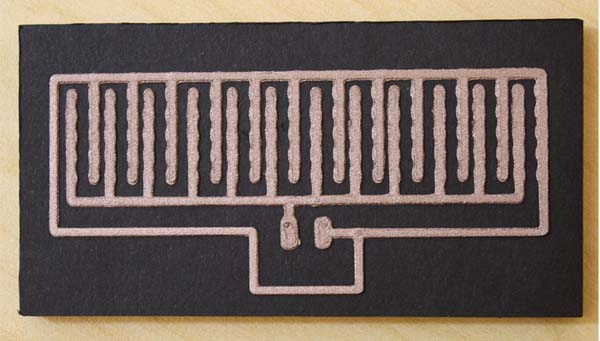

Researchers from Duke University have successfully 3D printed conductive metamaterials on a FDM machine. The process uses commercially available 3D printing filament containing conductive copper.

This material, Electrifi, was developed by a research group led by Benjamin Wiley in a separate research project conducted last year. Following its initial creation Wiley and Shengrong Ye, who both also worked on this latest project, founded a startup Multi3D LLC to sell the material.

This latest research titled ‘Microwave metamaterials made by fused deposition 3D printing of a highly conductive copper-based filament’, has been published in Applied Physics Letters. The development showcases the potential of creating three-dimensional electromagnetic devices on accessible FDM 3D printers.

Microwave metamaterials

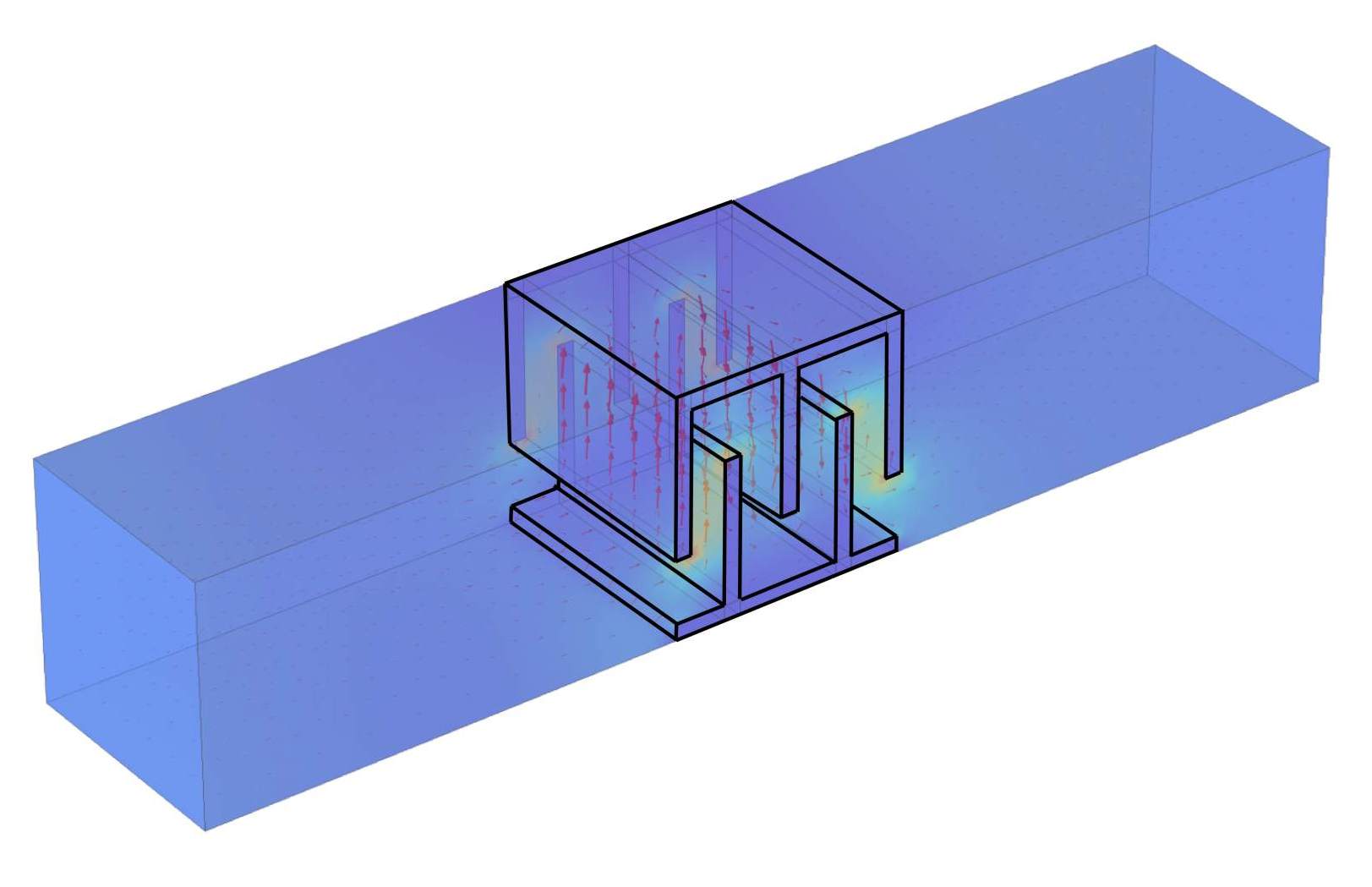

Metamaterials are synthetic composite materials with advanced qualities. The research explains that microwave metamaterials “are engineered materials designed to interact with electromagnetic waves and exhibit useful effective material properties.” It is for these effective properties that the researchers believe Electrifi could drastically change the production of communication devices such as Bluetooth and Wi-Fi.

The presented method not only allows reliable and convenient fabrication of microwave metamaterials with high conductivity but also opens the door to exploiting the third dimension of the unit cell design space to achieve enhanced electromagnetic properties

Accessing this third dimension is important as it will allow broader access to the creation of metamaterials and also enhance the design options. Steve Cummer, part of the research group and professor of electrical and computer engineering at Duke explained the importance of this development. “There are a lot of complicated 3-D metamaterial structures that people have imagined, designed and made in small numbers to prove they could work. The challenge in transitioning to these more complicated designs has been the manufacturing process.”

Cummer states that, “the ability to do this on a common 3-D printer, anyone can build and test a potential prototype in a matter of hours with relatively little cost.”

Potential of conductive metamaterials

While Electifi is not as conductive as pure copper, the filament is shown in the research to react very strongly to electromagnetic waves and almost as much as pure copper. Impressively, the 3D printed metamaterial takes this further as the cubes can interact with electromagnetic waves 14 times better than 2D counterparts. The team managed this by developing specific structures to cater to the electromagnetic waves.

Benjamin Wiley, Duke associate professor of chemistry, explains the potential

We think this could change how the radio frequency industry prototypes new devices in the same way that 3-D printers changed plastic-based designs. When you can hand off your designs to other people or exactly copy what somebody else has done in a matter of hours, that really speeds up the design process.

3D printing at Duke University

This research adds to the growing number of innovations developed at Duke University in North Carolina. In recent months, Duke University has created an online database of 3D printable lemur scans, incorporated cloud based software to manage its 3D printer farm and developed 3D printed cartilage with hydrogel material for knee implants.

This month the winners of the 3D Printing Industry Awards will be announced and voting is still open to decide the winners.

For the latest 3D printer news, subscribe to our newsletter and follow us on twitter.

Featured image shows illustration of 3-D-printed metamaterial unit cells. Image via Duke University.