The scientist who helped developed nanotechnology for the next generation of flexible and wearable electronic devices is now bringing affordable 3D printed electronics to anyone with access to a basic 3D printer.

3D printed electronics are already in use for smartphone manufacture and 2017 will see the next generation of printers powered by quantum mechanics to produce multilayer Printed Circuit Boards (PCBs). But what about 3D printing electronics with the tools available at home, or at the local Makerspace or FabLab?

A chemistry professor from Duke University might have the answer. “For the price one of those [industrial] machines you could buy a thousand of the printers we’re using, which are $200 3D printers,” says Ben Wiley.

“Our expertise is in copper, particularly copper nanowires,” says the professor of Chemistry at Duke University. With this knowledge of materials science Wiley and a postdoctoral researcher set about developing a conductive 3D printing filament they call Electrifi.

Copper: conductive and cheap

Copper is widely used in the manufacture of electronics because of two appealing characteristics, price and performance. Compared with silver, “Copper is 100 times cheaper,” says Wiley. Like silver, copper is highly conductive but unlike the precious metal it is more frequently used in devices such as smartphones.

In common with many other materials, copper only performs at this level when prepared in an optimal way. For example, graphene, a carbon-based material, is theoretically highly conductive and incredibly strong. However, these properties are reduced or even lost altogether during some common manufacturing techniques.

Graphene’s strength comes from harnessing the same force that allows a gecko to walk up walls. In a flawless 2D graphene sheet bonds between atoms make it one the strongest materials in the world. In this form graphene is also a zero-gap conductor. But, producing flawless single sheets of graphene for commercial use is a challenge science has yet to overcome.

There are similar barriers to the use of copper in 3D printing and this is a challenge scientists at NASA and other institutions are still working on. One of the issues with copper says Wiley, “Is when you have copper nanowires and you coat them down, its not conductive because they have this oxide layer.”

Wiley does not go into specific details of the conductive filament’s, ‘secret sauce’ but talking about his work with copper nanowires he says, “We were able to figure out how to make those [copper] films conductive.”

“Having worked for 6 years with copper nanowires, we’ve learned a lot about different ways to prevent copper oxidation,” says Wiley. The work has paid off and the volume resistivity of Electrifi filament is reported as 0.006 Ω cm.

Ohms per centimeter is a measurement of a material’s electrical resistance over a particular area, the lower that number then the easier it is for electric current to flow. As Wiley points out that resistivity is, “The largest scale.”

That scale ranges from insulating materials like rubber or Teflon, 1.00×1015 and 1.00×1027 ohms-cm respectively, to graphene at 1.00×10−6. In contrast a carbon based conductive filament using graphene has a volume resistivity of 0.8 Ω cm, about 100 times less conductive than Electrifi’s published figure.

A material for Makers (and more)

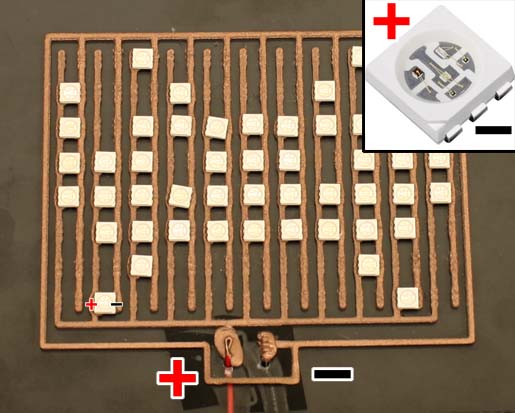

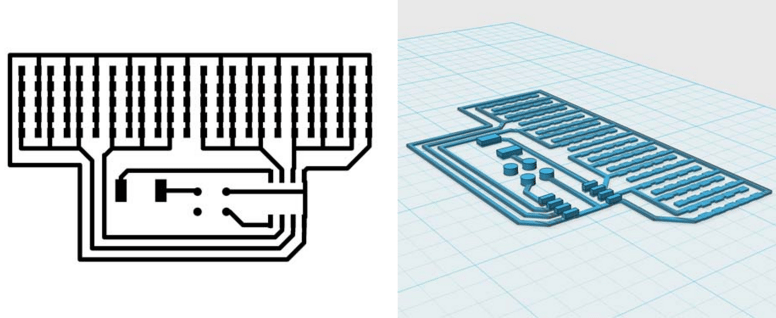

“We found we could print really quickly,” says Wiley. This means 3D printing, “Circuits in a few minutes on surfaces like foam board which are super-cheap and anyone can pick them up at the local target or Wal-mart.” A video shows 3D printing a circuit takes less than 5 minutes.

Continuing he says, “In terms of adding components like LEDs or micro-controllers, or buttons we found that you could just use a cheap heat gun and melt the filament slightly and then push your component into the filament to make an electrical connection.” This means, “No soldering required, no fumes or anything like that.”

Wiley designed the material with Makers in mind. “I’m most excited about making things for the FDM printers because they are so cheap,” he says.

As we recently reported, 3D printers are now available for under $50. “At that level it becomes like a Raspberry Pi or an Arduino, it becomes so financially accessible a huge community can develop around it. I was most excited about making a material for that type of large community rather than the few people that could afford a $100k printer.”

“Up until now there hasn’t been much that connects the world of Arduino with 3D printing.” Through outreach work with Duke University, Wiley is in contact with educators who see the filament as a way to combine electronics and 3D printing. Students, “Can 3D print something like a temperature sensor that works with a cheap Arduino.”

Even saying all this, applications beyond the target audience may be feasible. At D.C’s Maker Faire Wiley received encouraging feedback from people in the Aerospace industry who said, “The filament would be great for making integrated antennas and electronics, like a satellite.”

At $119, Electrifi’s price tag is above that of regular filaments. But the material compares favorably in cost, and timesaving, to other options available to Makers. “We’re super excited about what this can do for someone’s time. With electronics where people often stop is, ‘Am I going to design my own PCBs now?’ or, ‘I’m tired of sticking all these wires in these breadboards.’ This fills a gap between working with a breadboard and actually sending away for PCBs,” explains Wiley. “Maybe what you can print yourself is not quite as high quality as a PCB, but you can do it right there in 10 minutes for $5.”

This, he says, compares favorably to “Waiting days or weeks and paying $50 – $100,” for a PCB in the mail. Wiley is optimistic these factors will encourage users as, “More people are willing to commit to that expenditure and time.”

Electrifi conductive filament is available on the Multi3D website. The company also sell components such as the WS2812, aka NeoPixel.

Applications include creating wearable electronics, possibly for conferences or cosplay, pixel art and LED Matrix displays. “If you want a [traditionally manufactured] custom LED sign its like $200-$300,” says Wiley, “I’ve been trying to come up with a way to make that more like $40-$50. I’m really excited for the Duke Students to take these to basket ball games.”