Norbert Heinz, a German engineer, and inventor has designed a low-cost granule extruder for desktop 3D printers, using household items and open source hardware. The invention costs under $25.

Heinz who describes himself as a ‘tinkerer’ uses only open-source software and hardware for his projects. In addition to inventing things, Heinz also promotes science education, especially ‘Physical Computing’, a combination of physics and computing. On his webpage, Heinz has a substantial amount of educational material and quite a few open-source projects ready to build such as a 2D dot matrix printer and a plotter made by converting a 3D printer.

He has also exhibited his inventions on shows like Make Munich 2019 where he was sponsored by the German automation corporation Siemens.

Fused particle fabrication

Pellet extrusion is also known as Fused Particle Fabrication (FPF) or Fused Granular Fabrication (FGF). The technology works like a regular FDM/FFF 3D printer except that the extruder melts granules or pellets of plastic which are fed through a hopper instead of a filament.

Pellet extruders are more commonly used in large-format 3D printers as they are able to extrude plastic at a sufficient flow for large diameter nozzles (1mm-25mm).

Pellet extruders for desktop printers can cost as much as $200 or more. In contrast to this Norbert Heinz made a pellet extruder using over the shelf supplies and 3D printed parts.

Home-made 3D printed pellet extruder

The parts used in the construction of Heinz’ extruder include a 3mm wood screw, a 5mm Teflon tube, a 3mm threaded rod, insulation paste, and a standard hotend. The plastic parts used to make the hopper feeder were 3D printed.

For material, Heinz used waste PLA and PET, which was gathered from old plastic bottles. The waste was converted into granules using a blender.

Heinz began his experiment by inserting a 3mm screw for extrusion through the metallic throat of a standard hotend. Although a 3mm screw did the job, it was only capable of processing very fine granules and did not work well with small or medium-sized pellets. Heinz then used a 6mm threaded rod passed through a small piece of Teflon tube. To accommodate the Teflon tube, the borehole in the hotend was widened. The results seemed better with this modification.

Next, the German inventor tried a thread with 0.5mm copper wire wrapped around it. The results were even better. It took a few experiments for Heinz to perfect his creation but he did it. The final version of the extruder uses a 3mm wood screw attached to a 3mm threaded rod and it gives the best results.

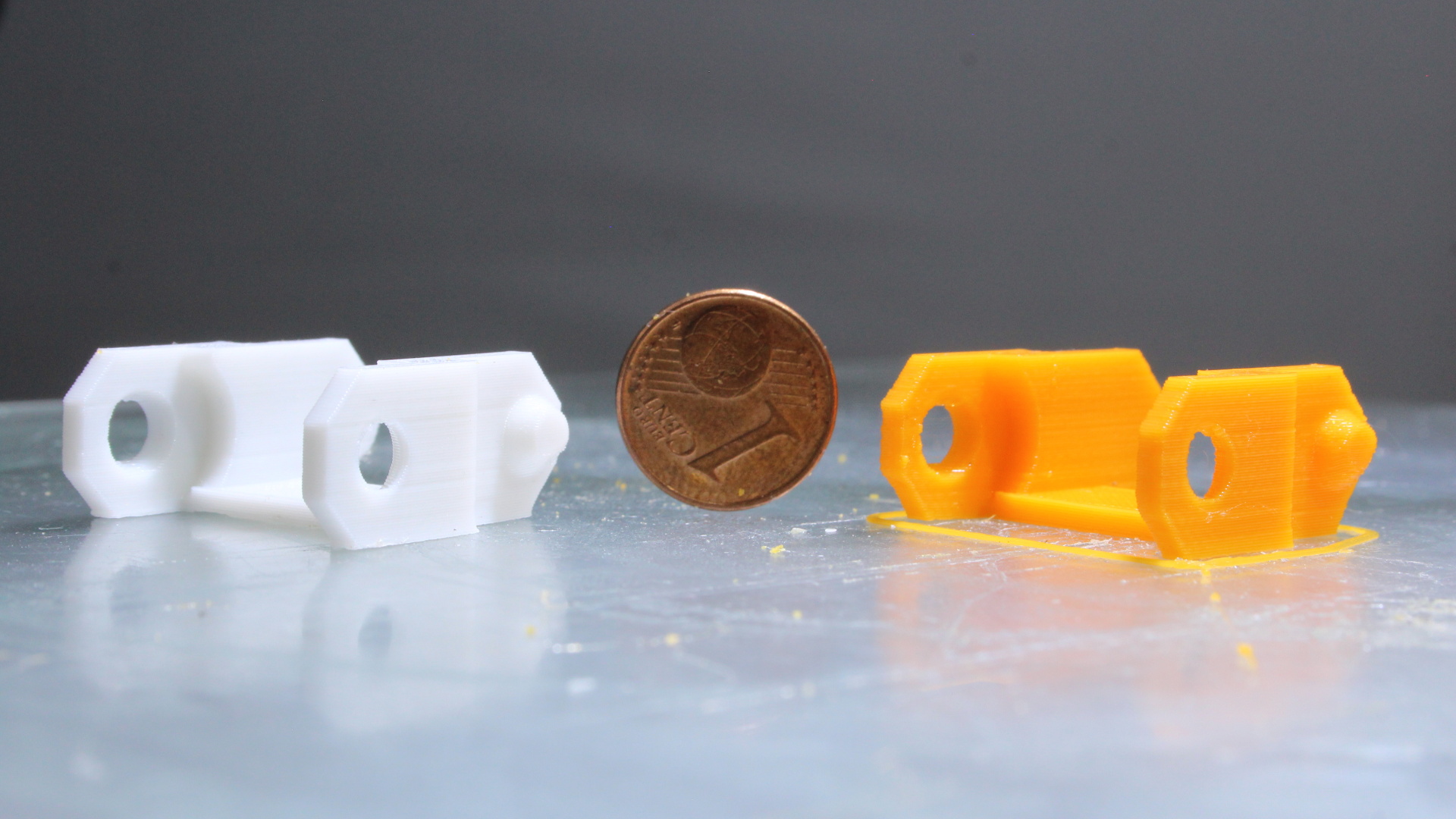

The extruder was attached to a Zonestar P802 series FDM/FFF printer made by a Shenzhen-based company. The concluding test shows that the Heinz efforts were a success. The image below is a 3D printed part using PLA granules with a layer height of 0.2mm.

STL files of the 3D printed parts can be downloaded here

To learn more about open-source projects subscribe to our 3D printing newsletter and join us on Facebook and Twitter.

Looking for a job? Visit our 3D Printing Jobs page.

Featured image shows a 3D printed part with the granule extruder (Right). The comparison part on the left is printed with Ender 3. Image via homofaciens.