Voting shortlists for the 2021 3D Printing Industry Awards are now open. Who do you think should receive top honors this year? Have your say now.

Interested in tuning in? The Youtube livestream page is also live, so viewers can now subscribe and set event reminders to ensure they don’t miss out.

Swiss Youtuber and engineer Ken Pillonel (aka Kenny Pi) has harnessed the power of 3D printing to create what he calls the “world’s first USB Type-C Apple iPhone.”

Modified using a combination of desktop 3D printing and soldering, the engineer’s custom smartphone is capable of both charging and exchanging data via a conventional Type-C cable. After years of rumours that Apple will launch a Type-C device of its own, Kenny Pi’s hack could help iPhone fans to finally fulfill their dreams of being able to charge all their electronics, using a single proprietary connector.

Finally, a working Type-C iPhone?

Although Apple has slowly switched the ports on its MacBooks and iPads from that of its own lightning cable to the more widely-used USB Type-C configuration, it has yet to make the same leap with its iPhone range. This is despite rumours dating back to the launch of the iPhone 8, that Apple would finally be creating a Type-C smartphone, and new EU regulations that could force it to adopt universal chargers.

Enter Swiss Federal Institute of Technology’s (EPFL’s) Ken Pillonel, an engineering student with a panache for using additive manufacturing to overcome daily tech problems. Last year, in a precursor project to that of his new iPhone, the engineer found he was able to create a car mount for his Galaxy Fold using a Prusa MK3s 3D printer, which allowed him to charge the Type-C-powered device on the move.

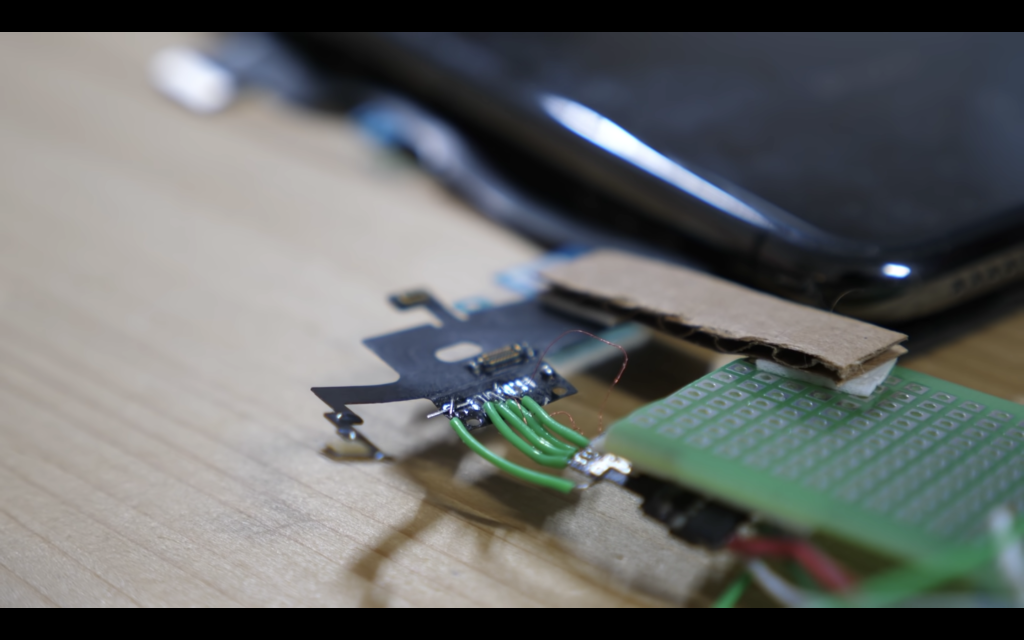

Since then, the Youtuber has taken his learnings from the Fold project and applied them on a new level, unveiling a modified USB Type-C-powered iPhone on his channel in May 2021. Developed over the course of around three months, Pillonel’s initial prototype functioned using a unique breakout board that he had customized to read Type-C cables, by hardwiring Apple’s proprietary ‘C94’ connector into it.

Featuring a modified female Type-C port, this board could effectively be connected to a custom iPhone and serve as a replacement for its female lightning port, enabling any type of cable to charge or transfer data to it, albeit at the cost of convenience and lugging around a cumbersome piece of circuitry.

Kenny Pi’s modded iPhone V2

While Pillonel’s first iPhone prototype worked as planned, in that it supported both USB Type-C fast charging and data transfer, he has now developed a more condensed version of his device. By simplifying his original design, removing much of its cabling and soldering it onto a custom PCB, the engineer has managed to squeeze his charging adapter and Type-C port into a regular iPhone X.

To accomplish this, Pillonel says that he has had to reverse engineer Apple’s C94 connector in a way that enabled it fit onto the head of a miniaturized circuit board, and he uploaded a teaser of a working model on October 8. As of yet, the engineer hasn’t revealed exactly how he managed to shrink the PCB down to size, but his preview does reveal that he relied on 3D printing to make the process possible.

Similarly, it’s currently unclear whether the engineer plans to make the 3D model of his mod open-source, as he did with his Galaxy Fold mount, which is available to download via Thingiverse. However, the Youtuber is now said to be editing a full-length video on the PCB ahead of its release, which could not only reveal the secrets behind his approach, but finally fulfill the dreams of iPhone users everywhere.

Youtuber-driven AM innovation

Using desktop 3D printing, Youtubers continue to break the mold (and often the warranties) of modern tech, with the aim of solving the 21st century’s first-world problems. Very much in this vein, Youtuber electrosync 3D printed a ‘bevvy boat’ earlier this year, which is designed to allow users to transport snacks across swimming pools, without ever having to suffer the inconvenience of getting out.

Ahead of the launch of Valve’s upcoming games console, Handheld Obsession has also deployed 3D printing to create a full replica of the Steam Deck. Using his prototype, the Youtuber has been able to provide his viewers with a hands-on preview of the device’s look and feel, as well as raising some initial concerns about its ergonomics and button placement.

Elsewhere, in even more ambitious applications, Youtubers such as Lucas VRTech have set out to improve the accessibility of advanced tech to everyday enthusiasts, and in April 2021, he managed to develop 3D printed open-source VR gloves. Costing just $22 to make, the student engineer’s devices are said to be capable of precisely tracking users’ fingers, without any need for pricey VR controllers.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Ken Pillonel’s new iPhone Type-C protoype being charged. Photo via Beebom, Ken Pillonel.