In the Gaza strip, blockades, economic downturn, and persistent conflict have made medical equipment and resources scarce and unaffordable. NGOs have been left to help with medical care, with Medecins Sans Frontières reporting that it performed most of its burns treatment and surgical operations on children under 16.

However, even bringing medical equipment into Gaza through either Egypt or Israel has become increasingly difficult. To address this, members of the voluntary Glia medical project are using self-built 3D printers from inside Gaza to create what they cannot secure.

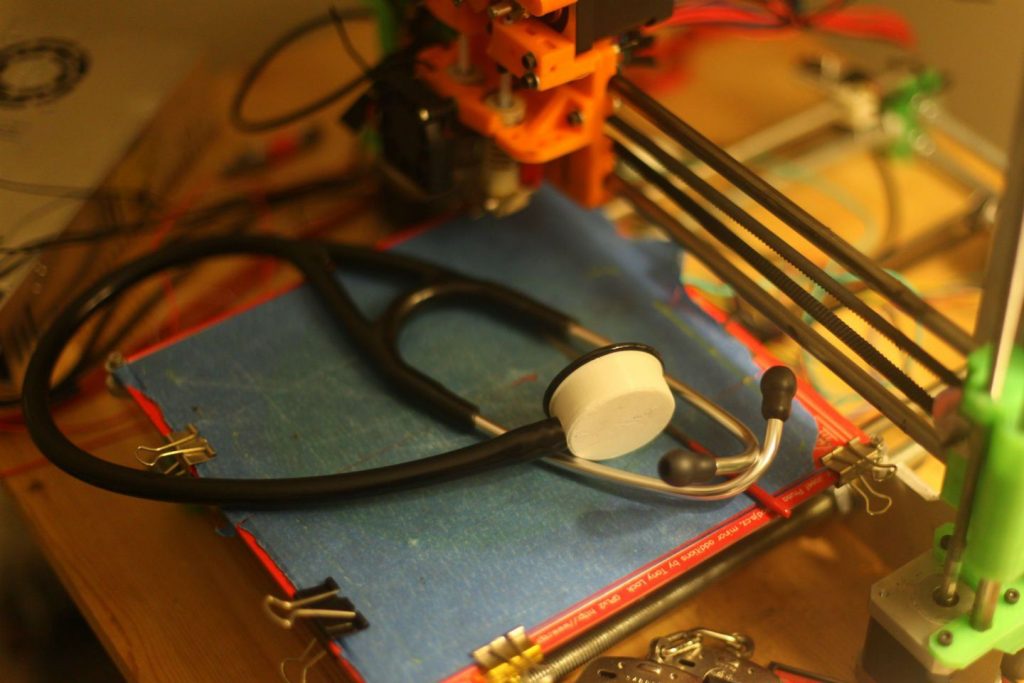

Stethoscope .stls

Dr. Tarek Loubani from Canada founded the Glia medical project to address the problem of scarce supplies in Gaza’s Al-Shifa hospital. The project provides free and open-source 3D printable medical equipment made from ABS/PLA plastic to those who most require it.

Dr. Loubani’s project first came to prominence after he designed a 3D printed stethoscope, found to be as effective as leading stethoscope brands and produced at a fraction of their price.

Since then, the stethoscope has been freely available as a set of .stl files and undergoes constant updates and refinements.

The next step

Another Glia project member, Mohammed Abu Mattar, decided to 3D print components for air ionisers and ozone generators which he was unable to obtain elsewhere. These expensive pieces of medical hardware are necessary for removing airborne bacteria and sterilising surgical instruments respectively, yet they are scarce in Gaza.

The main obstacle facing him, however, was the ban placed on 3D printers in Gaza by Israel, owing to the possibility of the machines being used to develop weapons. To circumvent this, Mattar built a 3D printer himself using spare parts and open source designs, even creating his own plastic filament from plastic pellets.

Mattar’s initial machines have developed into Gaza’s first 3D printing company: Tashkeel 3D.

Oximeters, CT scanners and MRIs are all blockaded or in scarce supply across Gaza. The Glia project hope to advance 3D printing across Gaza to such an extent that these machines can eventually be assembled from a mixture of spare and printed parts. Prototypes for pulse oximeters have already been released.

In case of emergency

3D printing is already transforming humanitarian aid. However, in a location like Gaza, expertise and equipment is constantly in mortal danger. Explaining his reasons for bringing printers to institutions across Gaza, Loubani stated that “if we all get killed in the next war, there’s two or three more places that can keep going.”

The project now hopes to introduce 3D printing and machine assembly to primary and secondary education in Gaza.

For more on the humanitarian applications of 3D printing, subscribe to our newsletter, Twitter and Facebook feeds.

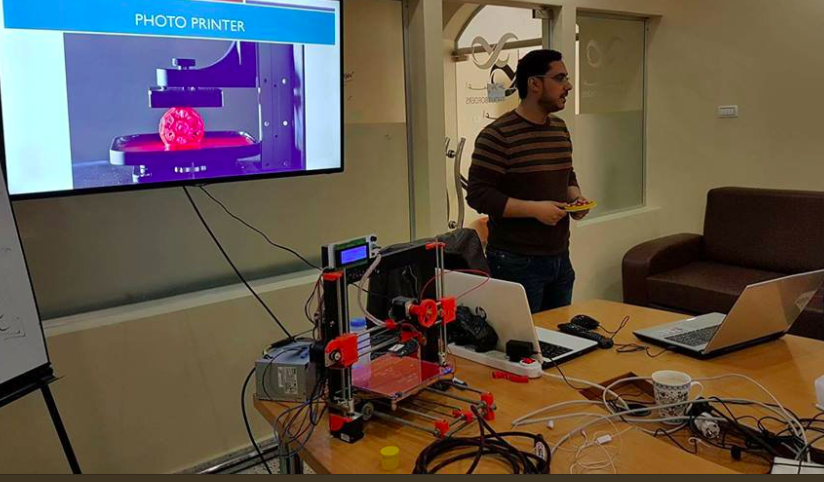

Featured image: Glia project members assemble a 3D printer. Picture via: Twitter/@trklou