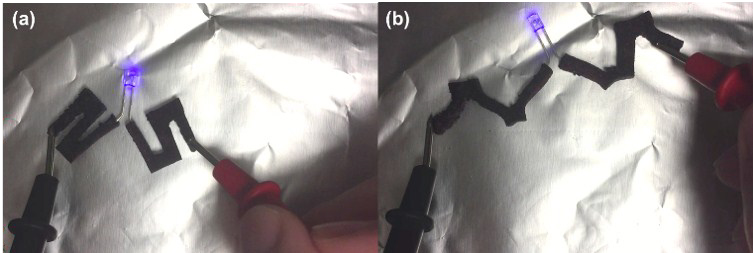

Research from the George W. Woodruff School of Mechanical Engineering at Georgia Institute of Technology (Georgia Tech) in Atlanta, demonstrates a method combining 3D printing with salt leaching to produce porous materials. Material porosity is especially useful in medicine, where it is used as a scaffold for growing tissue or, when combined with a conductive ink, it can be used to create flexible electronics.

The process

In this study, researchers mixed salt granules into three photo curable resins used for DLP 3D printing: extra-fine PEGDA, Standard Clear and Spot-E Ink. Once 3D printed, each object is then suspended in a 2000 mL beaker of water to dissolve the salt and create small holes.

Different granule sizes of salt, from coarse to extra-fine, were experimented with to understand the variety of porosity that can be achieved in this method. Though desirable for microscopic pores like those found in the body, ultra-fine salt did provide some difficulty in this method.

The authors explain that the salt being so fine created more of a paste in the resin and, as it is “encapsulated by the cured polymers”, it cannot be leached out.

Spongy, Droste and bone-like conclusions

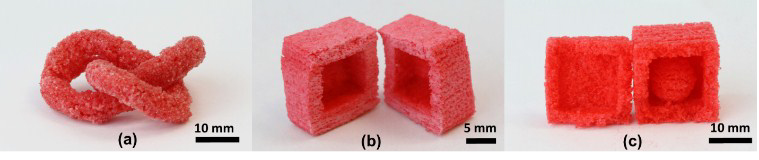

In determining the limits of the method, researchers were able to create structures that could retain some memory when squashed. A refined form of this would be useful in recreating the spongy, cancellous structure found in the center of bones. Additionally, the study also experimented with swapping inks during the 3D printing process, creating an object with varied porosity, again closer to the composition of bone.

The overall conclusions show,

This method is very simple to implement for different photocurable resins to create 3D porous objects with complicated shapes. In addition, this new method has the advantages of self-supporting and can be used to print hollow components, especially the part with Droste effect (one object within another).

Porous polymeric materials by 3D printing of photocurable resin is available to read online in Materials Horizons journal 2017. The research is co-authored by Xiaoming Mu, Thompson Bertron, Conner Dunn, Haipeng Qiao, Jiangtao Wu, Zeang Zhao, Christopher Saldana and H. Jerry Qi.

3D printing in MakerSpaces and heart procedures

Georgia Tech is one university in the US that has embraced the utility of MakerSpaces for students. A number of the facilities have been opened by the university in specific schools, including one for Materials Science and Engineering in the Materials Innovation & Learning Lab.

In December 2016, 3D Printing Industry also reported on Georgia Tech’s development of personal 3D printed valves that can be used in planning for heart procedures.

To stay up to date on the latest research relating to 3D printing sign up to the 3D Printing Industry newsletter, and follow our active social media channels.

You can also vote now in the 1st annual 3D Printing Industry Awards.

Featured image shows Plain ‘ol “quality” iodized salt. Photo by theUdødelig, rankingfuuta on Flickr