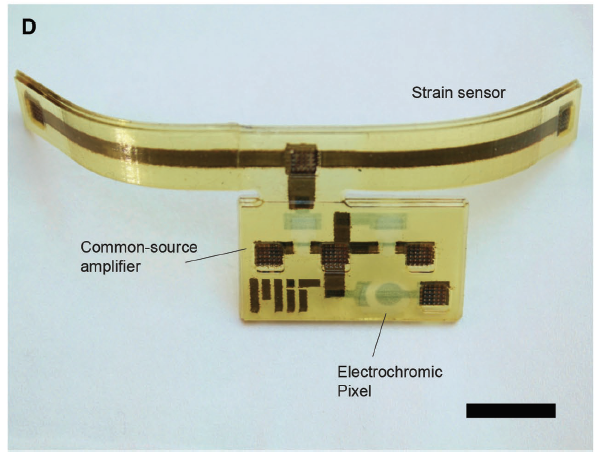

As current electronics are easily breakable, researchers are looking to develop a way to make them more flexible, and intuitive. With 3D printing, one project from the Computer Science and Artificial Intelligence Lab (CSAIL) at MIT has fabricated a jelly-like electronic device that changes color when under pressure.

The hope is that one day such research could lead to intuitive skins for robots, or skyscrapers that can adapt to external changes caused by the weather and other stresses.

Note the change in color of the inset left “pixel”. Clip from 3D-Printed Autonomous Sensory Composites by MIT Computational Fabrication Group on YouTube

Beetle-inspired design

The color changing aspect of this device is inspired America’s native golden tortoise beetles. As the name suggests, the shell of these beetles is typically gold, but it turns red when pressure is applied .

Speaking to MIT News, lead researcher Subramanian Sundaram explains,

In nature, networks of sensors and interconnects are called sensorimotor pathways. We were trying to see whether we could replicate sensorimotor pathways inside a 3-D-printed object. So we considered the simplest organism we could find.

Multimaterial 3D printing

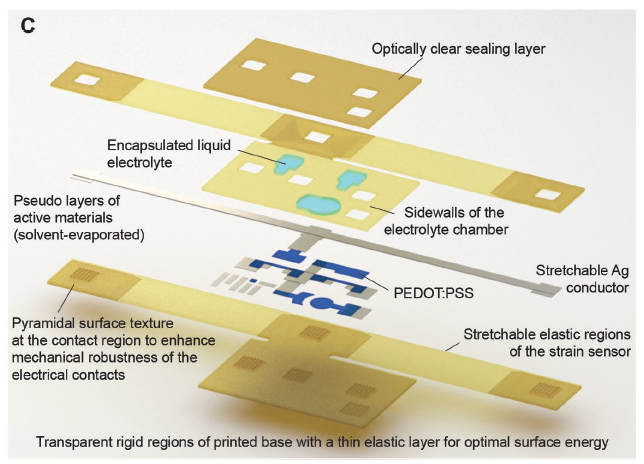

This flexible device is 3D printed on CSAIL’s custom MultiFab 3D printer which is capable of 3D printing up to 10 different materials at once. It is composed of four layers that be explained as follows.

Layer one: the base

This itself comes in two layers to give varied stiffness and elastic properties. The bottom is made in an polymer containing electrical materials which is cured using UV light. On top of this, there is a fused layer of elastics, used to interact with subsequent “pseudo-layers” of solvents.

Key points of this base strip are also designed with a grid of pyramids to ensure attachment of the second silver layer.

Layer two: conductive silver and reactive “pixel”

A trace of silver is created using a liquid ink that deposits the metal when heated. Precipitation in this way makes the silver stretchable, as it is in direct contact with the elastic layer below.

The active pixel elements of the device, (marked in dark blue in the diagram above) are layers of PEDOT:PSS – a plastic made conductive by the addition of potassium salt. The key to creating a reaction in this layer is water, carefully deposited in the third layer of the device.

Layer three: water wells

This layer caps the conductive layer below in the same UV curable polymer used for the base layer. This layer also encapsulates an amount of electrolyte water which is released on to the PEDOT:PSS when stress is applied.

The encapsulated water deems the device viable only for a couple of months, so further research will seek to replace this deposit with a material like a water-based hydrogel that lasts longer.

Layer four: the seal.

All previous layers are sealed by an optically clear rectangle at the top. Made again from UV reactive material, this top layer is designed with windows to leave silver pads exposed.

The whole construct is powered by an ordinary 1.5-volt battery, attached to the silver with wires.

The cutting edge at MIT

Other works to come out of MIT’s CSAIL include multi-material 3D printing software Foundry, dubbed “the Photoshop of 3D printing“. In 2016, the lab also demonstrated the ability to realize a walking robot in one single 3D print.

3D-Printed Autonomous Sensory Composites is published online in the journal Advanced Materials Technologies. It is open access, and available to read in full for free, including a supplementary video clip from MIT Computational Fabrication Group.

Project leader Subramanian Sundaram completed the paper with advisors Wojciech Matusik and Marc Baldo of MIT; and Pitchaya Sitthi-Amorn, Ziwen Jiang, and David Kim, who study at the university.

To stay up to date with 3D printed research at MIT sign up to the 3D Printing Industry Newsletter, follow us on Twitter and like us on Facebook.

Readers can also vote now for the best 3D printing research in the first annual 3D Printing Industry Awards.

Featured image shows a 3D-Printed Autonomous Sensory Composite from MIT CSAIL. Photo by Subramanian Sundaram