Foundry is a new interface from MIT’s Computer Science and Artificial Intelligence Lab (CSAIL) that helps users to create 3D printed objects made from multiple materials. What makes the software such a game changer is that the current method of designing a multi-material model has become so complex – Foundry breaks it down.

This development comes just over a year after CSAIL first announced its MultiFab printer in August of 2015. CSAIL is the largest research lab in MIT, ‘placing’ computational thinking squarely in the service of human need. The MultiFab printer is the first of its kind to be able to produce a composite object without the need for post-assembly.

You still need a CAD program for the initial design process, but after that Foundry allows you to add “Operators” to a model that define its material properties, and the software provides a detailed 3D render of the object so users can see what the end product will look like without having to go through multiple print runs.

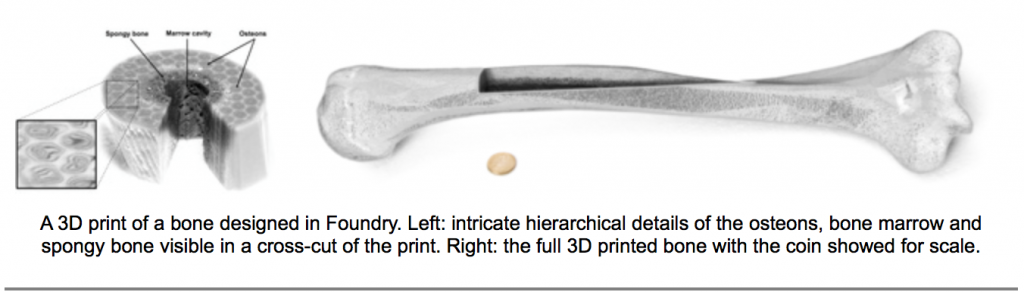

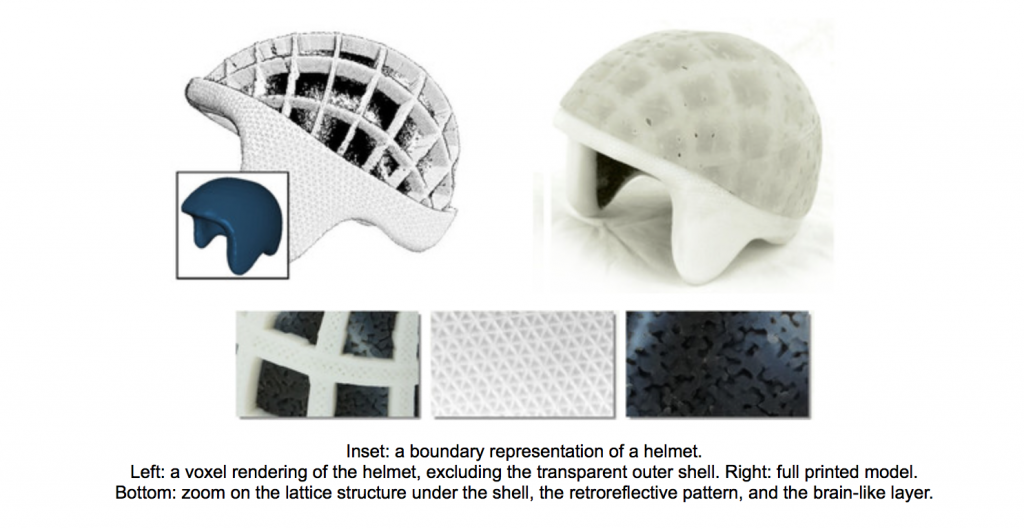

The program was tested by non-designers to prove how easy and logical it is to use. After a one-hour introduction, non-expert users in the test team succeeded in producing models for objects such as a teddy bear and a wheel for a child’s bike. Other example’s from CSAIL shows how they have managed to create a helmet, and a bone:

The natural state of materials was the initial inspiration for the research project, as material such as bone is required to be spongy yet solid at the same time. As 3D printing advances we are frequently seeing an overlap between the design forms found in nature and the optimal design for 3D printing, an interesting synthesis of biomimetics and topology optomization. In addition to exploring ‘natural’ constructs, the new software interface also means that multi material printing is one step closer to the sci-fi dream of meta-materials or materials that act in a way never seen before.

The goal here is to use 3D printing as a tool to create objects where material properties can vary throughout the structure: this opens up some exciting possibilities for working with functional materials. The UK’s National Physical Laboratory describe functional materials as those which, “exploit coupling between multiple variables – for example, transforming mechanical energy to electrical energy in piezoelectric materials, or providing electrical control of magnetic properties.”

Kiril Vidimče, researcher at CSAIL and one the authors of the paper Foundry: Hierarchical Material Design for Multi-Material Fabrication writes, “3-D printing is about more than just clicking a button and seeing the product. It’s about printing things that can’t currently be made with traditional manufacturing.”

The paper will be presented by the CSAIL team at the Association for Computing Machinery’s User Interface Software and Technology Symposium (UIST) in Tokyo later this month. UIST opens on 16th October and 2016 will be the 29th year it has been running. For the authors of the paper, Foundry is the product of years of research, with advisor Wojciech Matusik having studied the scattering properties of two kinds of wax as far back as 2006.

Kiril Vidimče, has acted as spokesperson for Foundry and his hopes for the future are to integrate Foundry’s workflow into existing CAD software, and to create a social platform for designers to share their innovative use of its operators.

It’s like Photoshop for 3-D materials, allowing you to design objects made of new composite materials that have the optimal mechanical, thermal, and conductive properties that you need for a given task. You are only constrained by your creativity and your ideas on how to combine materials in novel ways.