Researchers from Singapore have investigated the durability of 4D printed structures. 4D printing, opposed to 3D, is a term that relates to objects that can adapt over time once they have been 3D printed. The structures rely on shape memory polymers which are able to transform into a certain shape.

3D Printing Industry has reported on the potential of 4D printed structures recently with a separate study also from Singapore. In this case, researchers showcased the simplicity of fabrication and the application of 4D printed objects.

However, in a new study stemming from Nanyang, researchers evaluate the performance of these structures since, as they explain, “high shape fixity, shape recovery, and prolonged shape memory cycle life are desirable aspects of 4D printed parts; however, the durability of 4D printed parts is rarely investigated.”

The 4D printing process

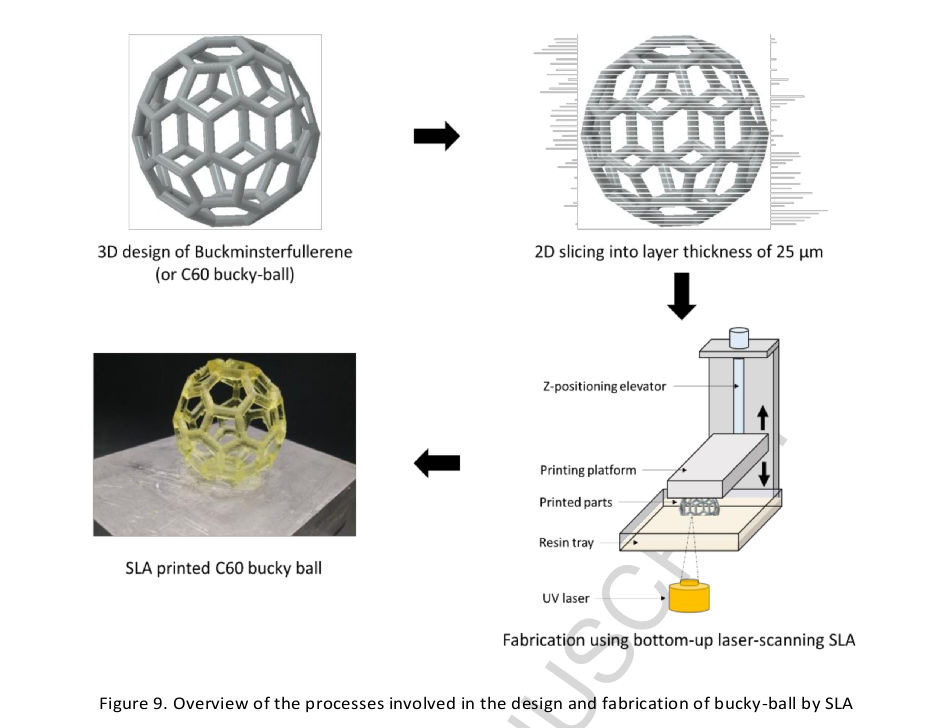

In order to test the viability of 4D printed parts the group tested the process by 3D printing a bucky ball shaped structure using a DWS SLA 3D printer.

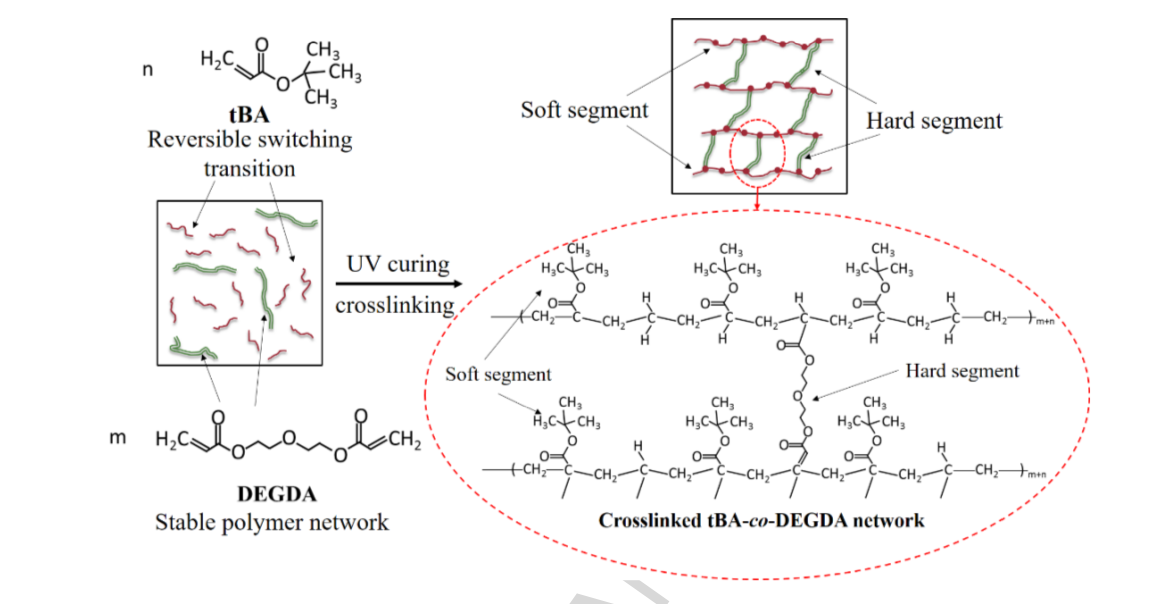

To carry out the 4D printing firstly, and most importantly, the team had to create a specially formulated resin. The resins that are commonly used in SLA machines “are highly crosslinked thermoset polymers,” which means that the parts produced are typically quite stiff and without desire properties for shape memory effect (SME).

To create the SME in an SLA-printed part, the single amorphous resin was formulated in a way consisting of “dual components”, namely a monomer and a crosslinker.

The fourth dimension

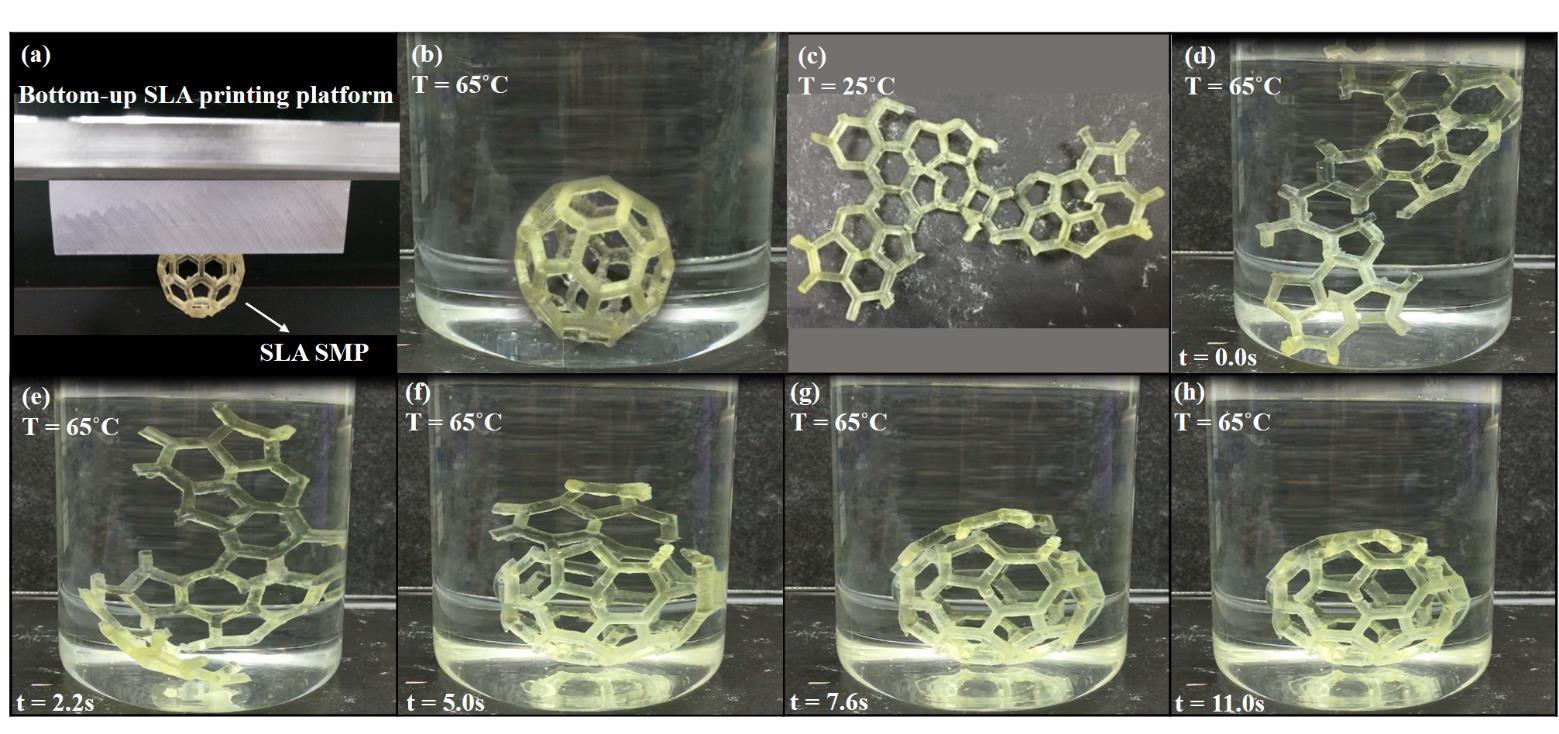

Following a number of different tests, the researchers were able to successfully create a resin that had different properties depending on the temperature of the environment it was exposed to. In addition, the group also demonstrated how different resins could affect the performance of the 4D objects. The team were thereby able to create a 4D printed spherical bucky ball which could be manually deformed to lie flat before then retaking shape when submerged in warm water.

The resulting object performed very well as the researchers described the 4D printed bucky ball as,

An outstanding durability of 22 cycles was demonstrated to show its prolonged shape memory cycle life.

Potential of 4D printing

This research could have an impact on the application of 4D printing as a viable manufacturing technique. 4D printing has strong potential for its ability to self-assemble objects, with particular interest in construction or for self-assembling flat-park furniture.

Elsewhere in the world, researchers at MIT have been exploring the application of 4D printing through their Self-Assembly lab. The lab has recently unveiled a new 3D printing method coined ‘rapid liquid’ printing. MIT has similarly explored the use of light to adapt 3D printed objects post-printing.

The paper, titled ‘4D printing of high performance shape memory polymer using stereolithography’, has been published in the ‘Materials & Design’ journal. The research was written by Yu Ying Clarrisa Choonga, Saeed Maleksaeedib, Hengky Engb, Jun Weib, and Pei-Chen Sua from the Singapore Centre for 3D Printing, School of Mechanical & Aerospace Engineering, Nanyang Technological University and the Singapore Institute of Manufacturing Technology.

Don’t forget to vote in next month’s 3D Printing Industry Awards.

For the latest news on 3D printing research, subscribe to our newsletter and follow us on twitter and Facebook.

Featured image shows a ‘4D Buckyball’ created by University of Edinburgh students. Photo via Graeme Taylor.