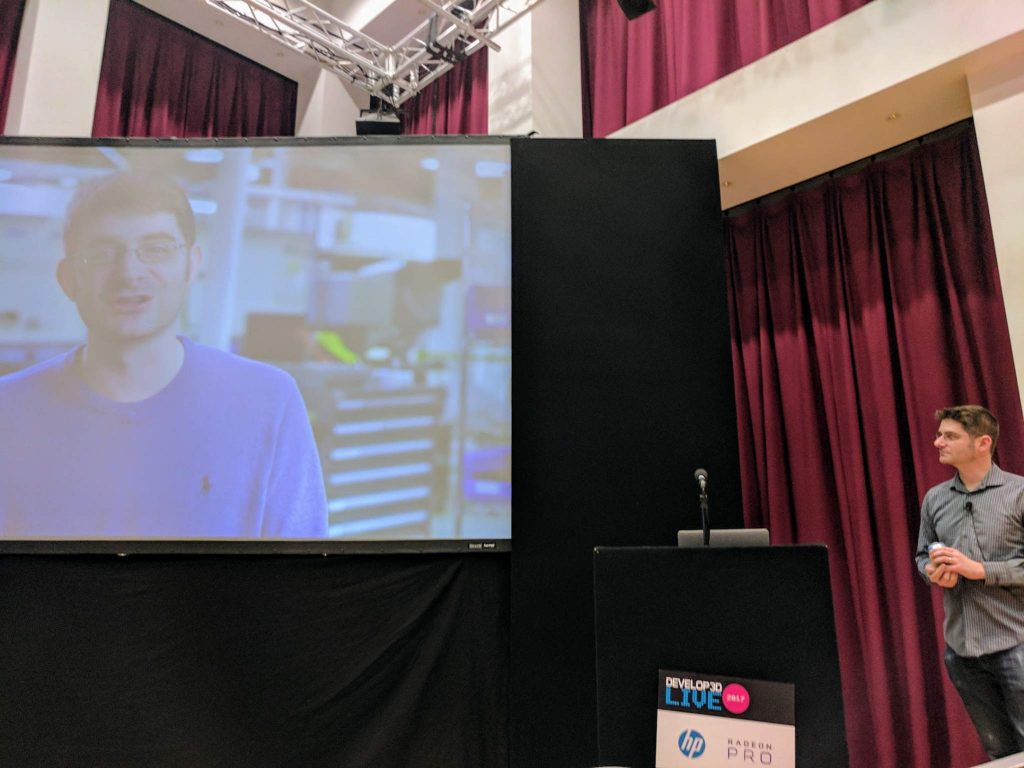

The future of metal 3D printing is in print farms says Markforged CEO, Greg Mark.

While a number of companies are attempting to create machinery capable of industrial metal 3D printing, Greg Mark believes these “large-format metal printers will be replaced by smaller, low cost machines working in parallel – print-farms.”

3D printing on a larger scale

Using the Metal X machine, which was unveiled at CES earlier this year, the company plans to scale up metal 3D printing production. Markforged believes that such a step will accelerate metal 3D printing technology and the manufacturing industry as a whole. Since, as Greg Mark says,

3D metal print-farms will shorten development time, closing the gap between prototyping and production.

Markforged intends to develop a system that allows for rapid production of strong metal parts. Often seen as just a prototyping tool, the Massachusetts company expects the use of 3D printing to drastically change in the future with the ability to produce functional metal parts on demand and with ease.

However, in order to do this one obstacle in the way is scale.

Metal 3D print farms

For Markforged, farming is the solution for large scale metal 3D printing production. Currently, 3D printing farms are mainly working with plastics. For example, New York additive manufacturing bureau, Voodoo manufacturing has set up an automated FFF printer farm that is now operated by an autonomous robotic arm.

To optimize the process for metal 3D printing, Markforged has sped up production with rapid sintering using a microwave furnace and will take a three-pronged approach to large-scale metal manufacturing.

Firstly, through their Atomic Diffusion Additive Manufacturing (ADAM) process which is enabled by the Metal X machine.

ADAM is an end-to-end process that starts with metal powder, captures it in a plastic binder (which makes it safe to handle), and then forms it into the part shape one layer at a time. After printing you sinter the part in a furnace, burning off the binder and solidifying the powder into the final fully-dense metal part.

The second step is through the 3D print farm platform and harnesses the Metal X’s advanced smart sensors. Finally, Markforged’s fleet management software will be used to control the workflow of a large number of connected printers.

“The future is so metal”

In the next 2 years Markforged will achieve the technological leap to true digital metal manufacturing. The digital age transformed every other industry known to man – music, photography, writing, telecom, email, the internet. But manufacturing is largely the same as it was in the 50’s. It’s time for mechanical engineering to enter the digital age.

Be sure to cast your votes in next month’s 3D Printing Industry Awards.

For the latest metal 3D printing news, subscribe to our newsletter and follow us on twitter and Facebook.

Featured image shows sample parts from the Metal X. Image via Markforged.