Nominations for the 2022 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Let us know by casting your vote now.

3D Printing Industry reviews the XYZprinting da Vinci Pro EVO 3D printer.

Founded in 2013, XYZprinting first made a name in the FFF 3D printing world with its suite of extrusion-based machines making the technology accessible to a much wider group. The latest addition to the XYZprinting portfolio is the da Vinci Pro EVO. Intended as a successor to the previously launched da Vinci 1.0 Pro, the single extruder FDM system comes complete with several feature upgrades that make it a system worth considering.

XYZprinting’s Pro Series is a versatile range, offering everything from economical entry-level systems to prosumer-level printers. Featuring a larger build volume, and automated bed leveling for a better user experience, the da Vinci Pro EVO offers more features than ever in a neat desktop setting.

The 3D printer is aimed at a wide range of potential users. These include casual hobbyists, educational institutions, and even professional designers and engineers looking for their next functional prototyping companion.

Building on the da Vinci 1.0 Pro

Out of the box the da Vinci Pro EVO impressed us, showing how XYZprinting cares about its printers. The da Vinci Pro EVO was extremely well packaged, and critical components were secured with clips. The 3D printer arrived with everything you need to start printing, including a 600g spool of PLA-CF, an 8GB USB stick, a WiFi dongle and some tools to keep the printer in good condition.

An all-in-one ecosystem

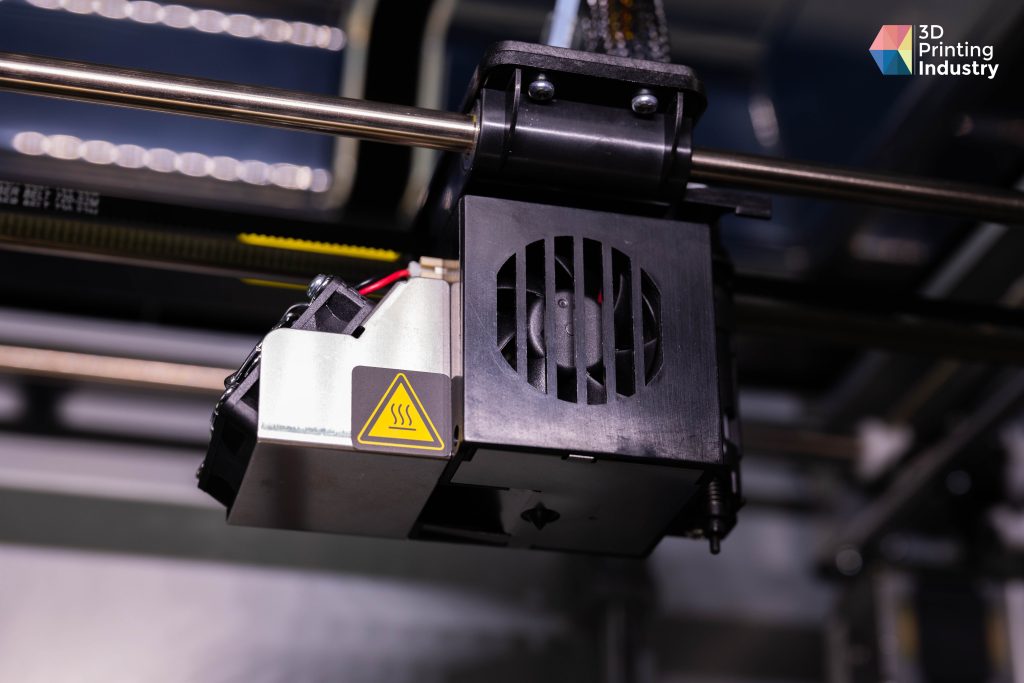

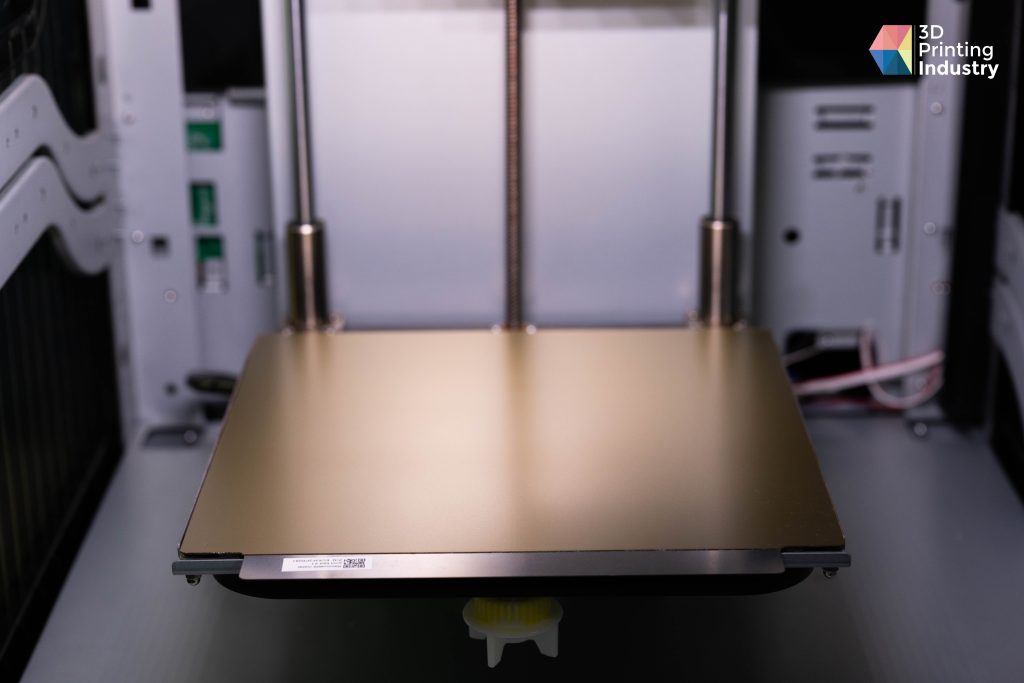

The da Vinci Pro EVO is remarkably robust and durable. Underneath the polymer casing is an all-metal chassis that ensures the stability and integrity of the machine. In line with its predecessors, the 3D printer also operates on a Cartesian configuration, a method known to be more rigid and accurate but slower than a delta or CoreXY system. The print head moves along the X and Y axis, while the bed moves along the Z axis. The printer has a fully enclosed print volume of 220x200x200mm, allowing users to print complex filaments without problems of delamination and deformation. The removable print bed is covered with a PEI sheet and is magnetic and flexible, making it easy to remove the parts once printed. After 852 hours of printing, we observed that the adhesive film on the surface of the build plate remained effective and fully intact. For the extrusion module, XYZprinting increases the temperature by 20°C compared to the da Vinci 1.0 Pro to 260°C. Having higher nozzle temperatures allows for even greater material compatibility.

Build plate and printhead of the da Vinci Pro EVO. Photos by 3D Printing Industry.

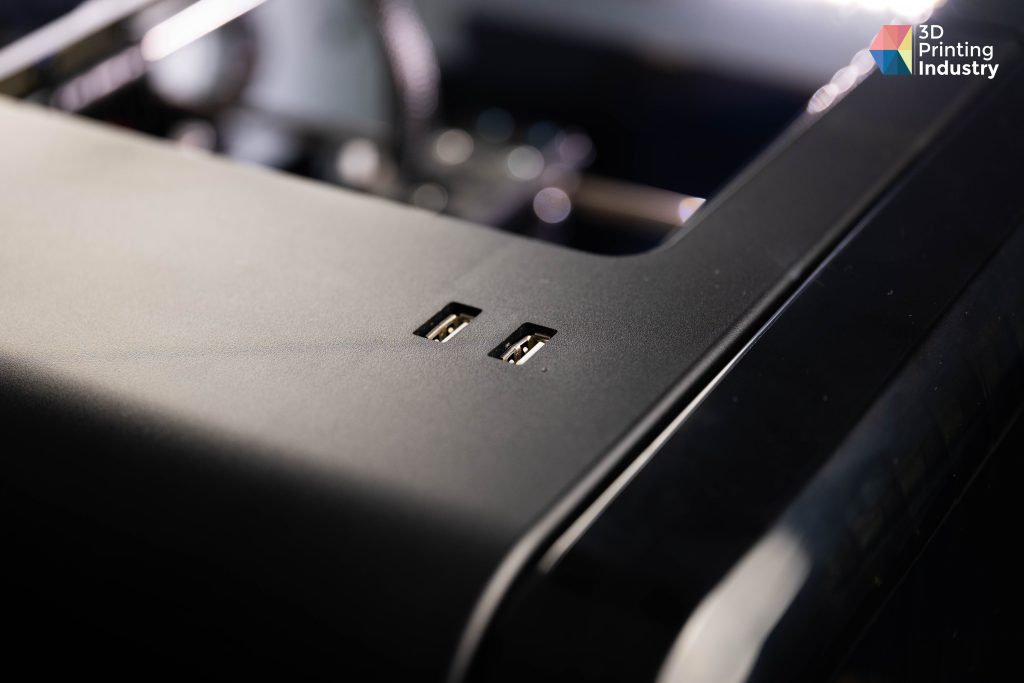

On the electronics side, connectivity options include Wi-Fi, USB cable as well as and USB flash drive. The Wi-Fi works great, and file transfer is very fast. Users have a 5-inch color touch screen on the front, which allows them to calibrate the bed, load the filament and start printing. After use, the user interface is intuitive and easy to use, and we didn’t encounter any bugs or lags, greatly enhancing our experience. The only thing that could be improved is the access to the parameters during the printing process (temperature, Z-offset, or print speed adjustment). To do this, you first have to go back to the main screen and then access the settings. Accessing the settings directly on the print screen would make them more accessible.

The touchscreen and USB port of the da Vinci Pro EVO. Photos by 3D Printing Industry.

Easy peasy with the XYZ

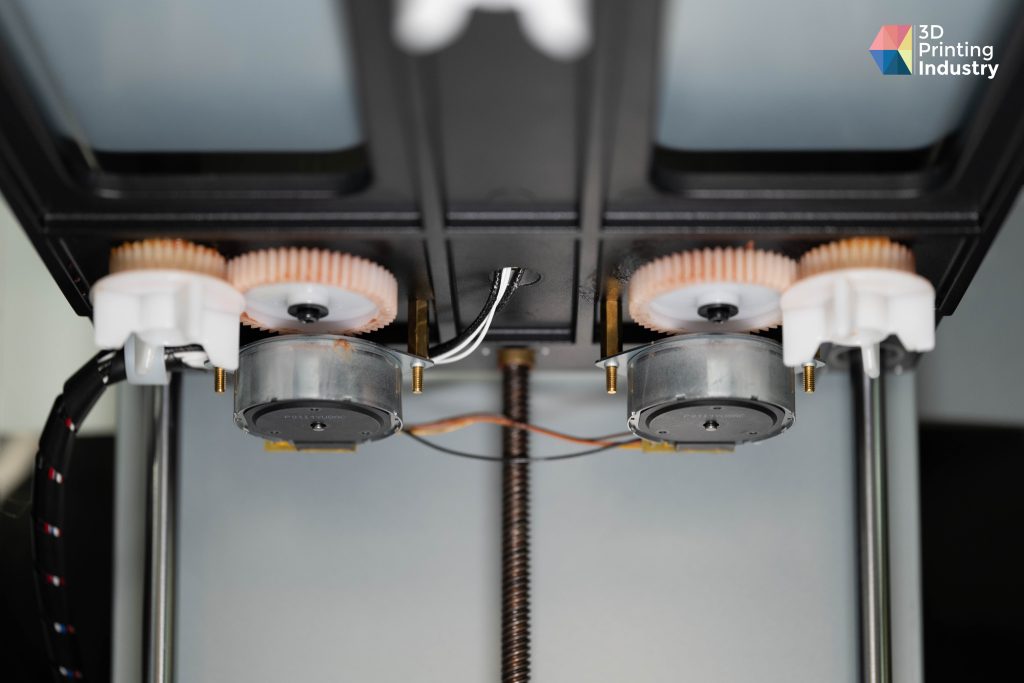

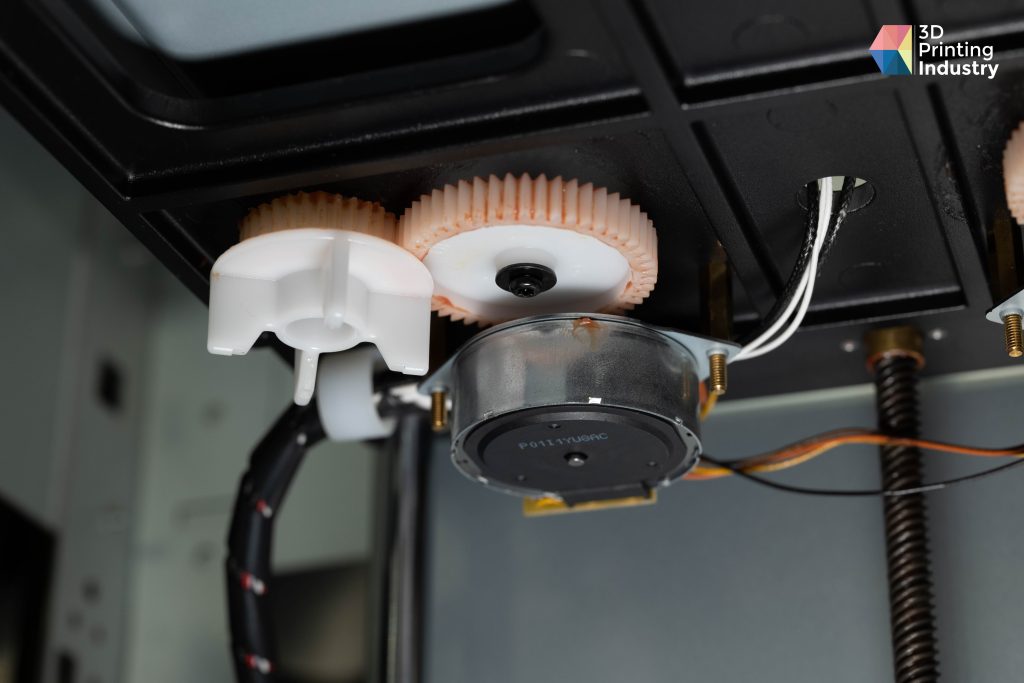

Naturally, XYZprinting’s latest machine also comes with all the quality-of-life features you would expect from a printer in this price range. One of the more innovative features is a pair of motors under the bed. After following the instructions to mount the print head on its carriage, install the PTFE tube and turn on the printer, it is now time to perform the first calibration of this machine. This takes place in two stages, firstly the sensor will probe the bed at three points to define its plane to make it parallel to the X and Y axis plane. Where with competitors we have to adjust the bed plane ourselves via screws on the underside, the two motors mentioned above allow this to be done fully automatically. The sensor will then create a mesh to correct the flatness of the bed in real time during printing by probing a matrix of 11×11, or 121 different points. With this, we are ready to print our largest creations.

Two motors under the bed. Photos by 3D Printing Industry.

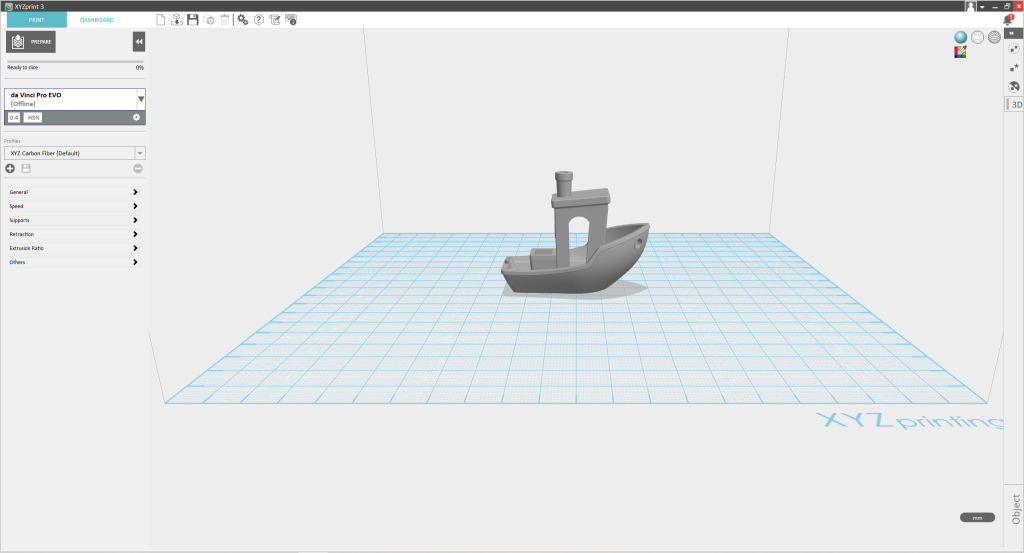

XYZ slicer: XYZprint 3

XYZ provides its own slicer software for use with its FFF 3D printers: XYZprint 3. Unfortunately, after shining so brightly in the previous hardware tests, this is where the printer’s biggest weakness lies. The user must first download and install the XYZmaker Suite software to finally have the choice between three different slicers depending on the machine used. This is the first time we have seen this, and it’s definitely not the best solution. In our case, we will then install and use XYZprint 3. With its old-fashioned grey and blue colors, this slicing software is not optimized and up to date.

Just like Cura or any other mainstream slicer, XYZprint 3 has basic function sets like translation, rotation, and scaling. There is nothing to report on this front. The software is easy to use, especially if you are already familiar with the FFF 3D printing workflow. Once the model is imported into the virtual build space, users can navigate through the various parameters. Whether it’s the profile used, the adhesion to the plate, or even the support settings, it’s all there, and the software is complete in this respect.

XYZ has even provided a “Basic” mode for beginners to avoid getting lost in a variety of settings. However, for the more advanced users, XYZ offers an “Advanced” mode, which allows you to modify all the printing parameters. This includes cooling profiles, temperatures, speeds, infills, and even retraction.

Overall, XYZprint 3 has everything we’ve come to expect from a slicer. But there are still a few things that need to be fixed. Between the few crashes during slicing, the auto-placement that overlaps objects, and the UI that is not optimized, we are sure that XYZprinting can quickly improve this by bringing updates.

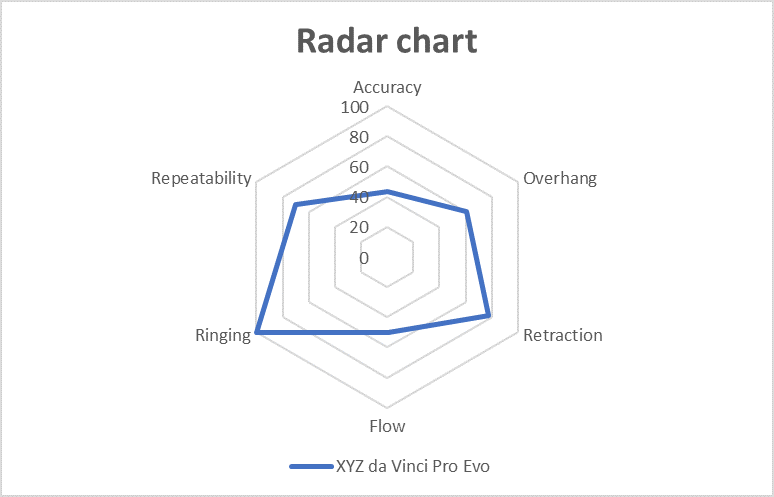

Benchmarking the da Vinci Pro EVO

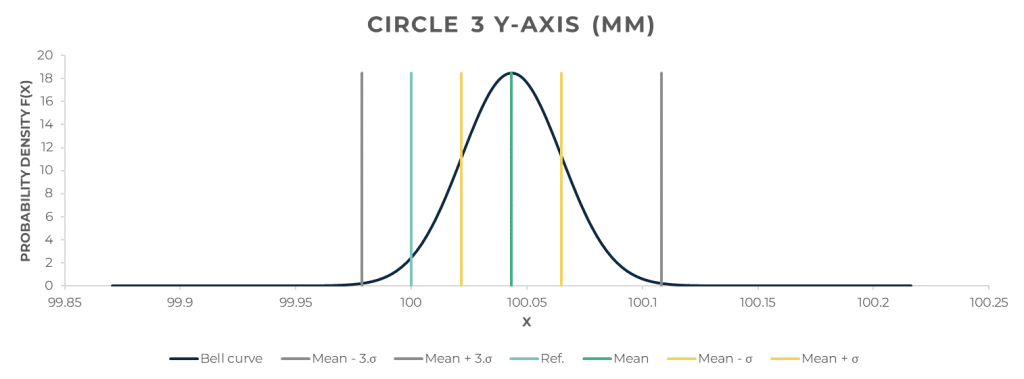

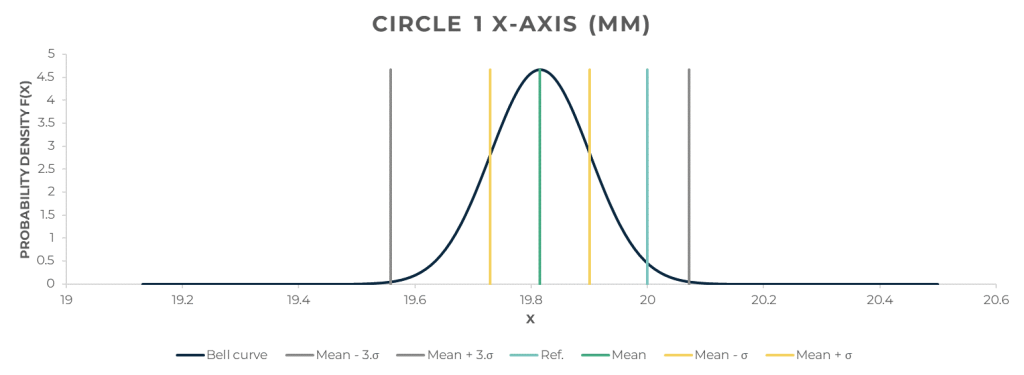

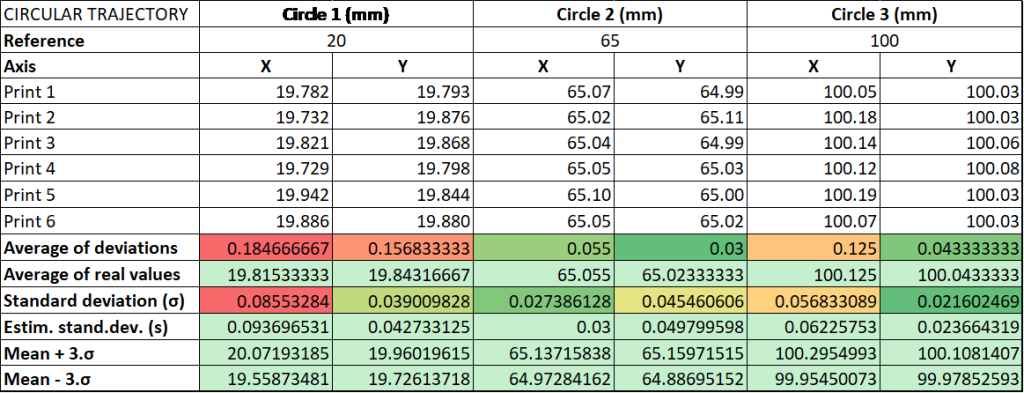

Now comes the benchmarking part, where we evaluate the printing performance of the da Vinci Pro EVO. We then 3D printed a set of circular trajectory test specimens to see how the XYZprinting would handle circular structures. By studying the normal distribution of the concentric circles’ diameters, we can say that the printer offers sufficient repeatability when the average deviation from the intended dimensions is under 0.1mm, and the standard deviation is under 0.05mm. Our measurement devices are accurate to ±0.015mm.

Circular trajectory test specimens. Photo by 3D Printing Industry.

XYZprinting showed above-average repeatability, with an average offset of 0.1216 mm for the X-axis and 0.0767 mm for the Y-axis, giving an average of 0.0991 mm for all axes. It should be noted that the Y-axis is significantly more accurate than the X-axis. It is therefore recommended to print along the Y-axis to produce parts with tight tolerances. The average standard deviation is also 0.046 mm, which is perfect for a printer in this price range. It should be noted that this printer has a feature that we think is great and not very common: a function to adjust the E-steps to increase the accuracy of the printer. E-steps are the parameters that tell the printer how many steps the stepper motor needs to take to advance one millimeter. Adjusting this parameter allows you to easily get a much more accurate printer than the average. Congrats XYZprinting.

Below you’ll find the bell curves for the best and worst circles in the test – circle three for the Y-axis and circle one for the X-axis. In the best case, 99.6% of the 100mm circles manufactured by this 3D printer will be between 99.98mm and 100.11mm. In the worst case, 99.6% of the 20mm circles fabricated by this 3D printer will be between 19.56mm and 20.07mm.

Best and worst results. Image by 3D Printing Industry.

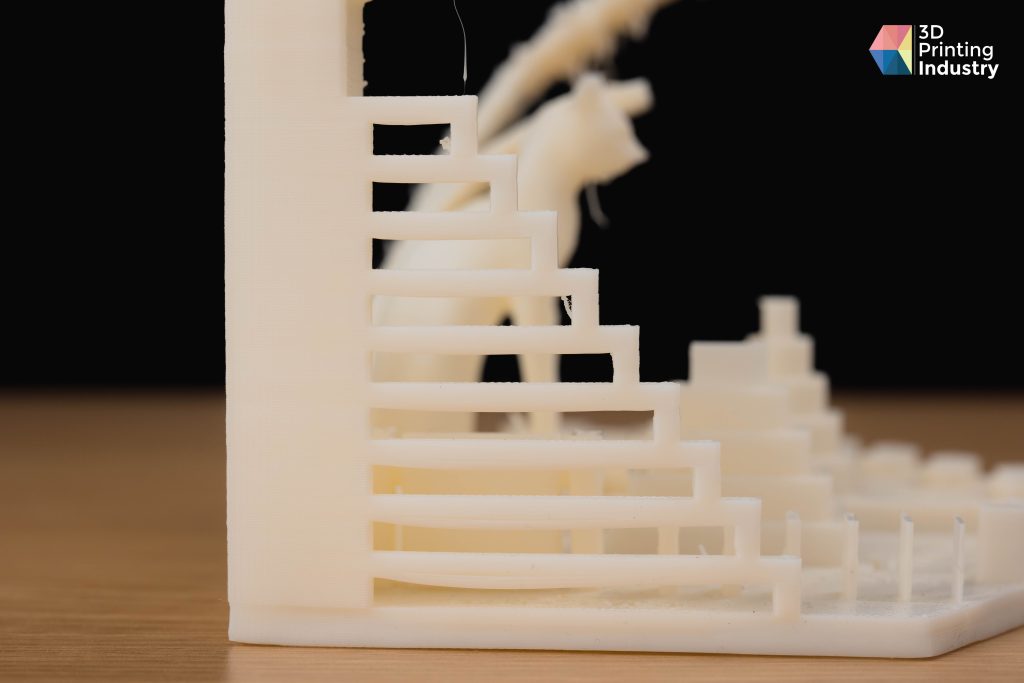

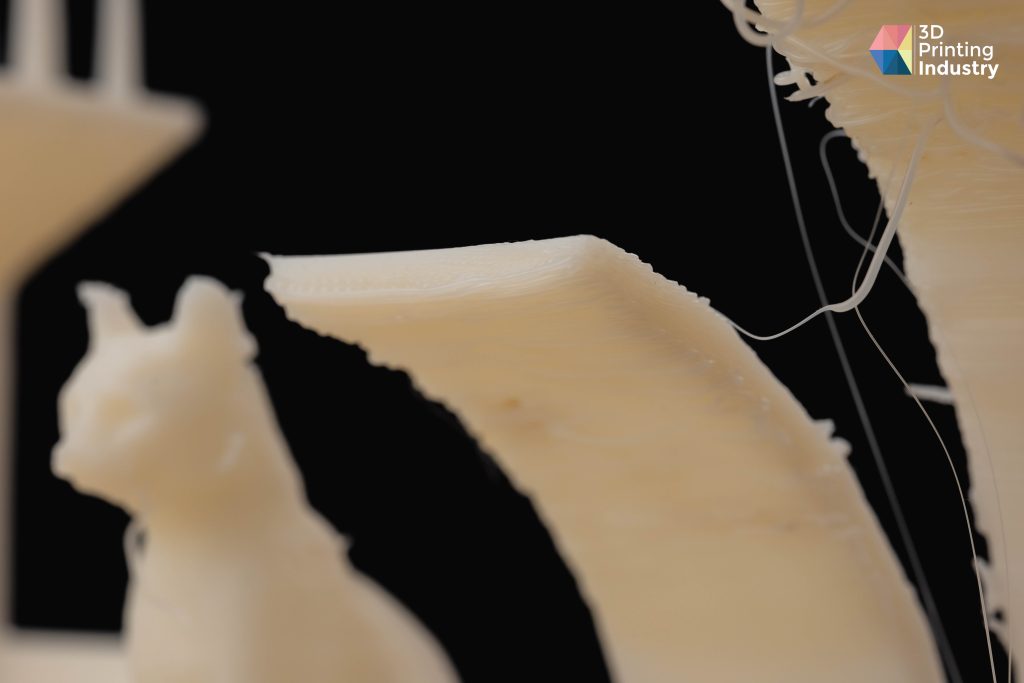

To continue this Benchmarking, we will now print 3D Printing Industry’s own benchmarking template, which combines several of our small print tests into one complete part. We usually print this test in PETG to understand how the printer handles this type of material. This time we decided to challenge the printer a little more by printing ABS. We give each individual section a weighted score based on factors such as dimensional accuracy, surface quality, and structural integrity. The da Vinci Pro EVO has achieved an overall score of 58.44/100 for 3D Printing Industry (a good professional grade 3D printer has a score of 60+).

3DPI benchmarking model. Photos by 3D Printing Industry.

Looking at the overhang section, which is designed to determine the angles at which the system is able to print without a support structure, the XYZprinting was able to print up to an impressive 45° without any problems. This is about average for a material as difficult as ABS. Next was the bridging test, which determines the ability of a system to print horizontally without a need for support materials. Like the overhang test, the bridging test yielded decent results as the da Vinci Pro EVO managed to reach the 35mm bridge length before the structures started to bend and morph, which is above average. To our surprise, the negative accuracy portion of the test was particularly well executed. We were able to remove five of the printed tubes, whereas we usually only manage to remove three or four before the contact area becomes too large. However, contrary to our expectations, the test that clearly lowered the printer’s average was the accuracy test. The materials shrank a lot after printing which greatly affected the score. The printer comes out fine with a score of 58.44/100 which is still very respectable for ABS.

Real application tests

Our final phase of testing the da Vinci Pro EVO turns to real-world applications or how you might want to use this 3D printer regularly. We started by pushing this machine to its limits by using more complex filaments. For this, we will use the PolyMaker PC-Max filament, with which we will print a print-in-place phone holder. Polycarbonate (PC) is a high-strength material intended for tough environments and engineering applications. It has extremely high heat deflection and impact resistance. It also requires very high temperatures for printing and will exhibit layer separation if printed at too low of a temperature or with excessive cooling enabled. Polycarbonate is frequently best printed on a machine that has an enclosed build volume and is capable of handling high bed and extruder temperatures. In our case, the result is perfect, and the printing went off without a hitch. Printed with a nozzle temperature of 260°C, which is the maximum temperature that this printer can reach, and a bed temperature of 95°C, this filament did not cause any problems in terms of warping and delamination between layers.

PC phone holder model. Photos by 3D Printing Industry.

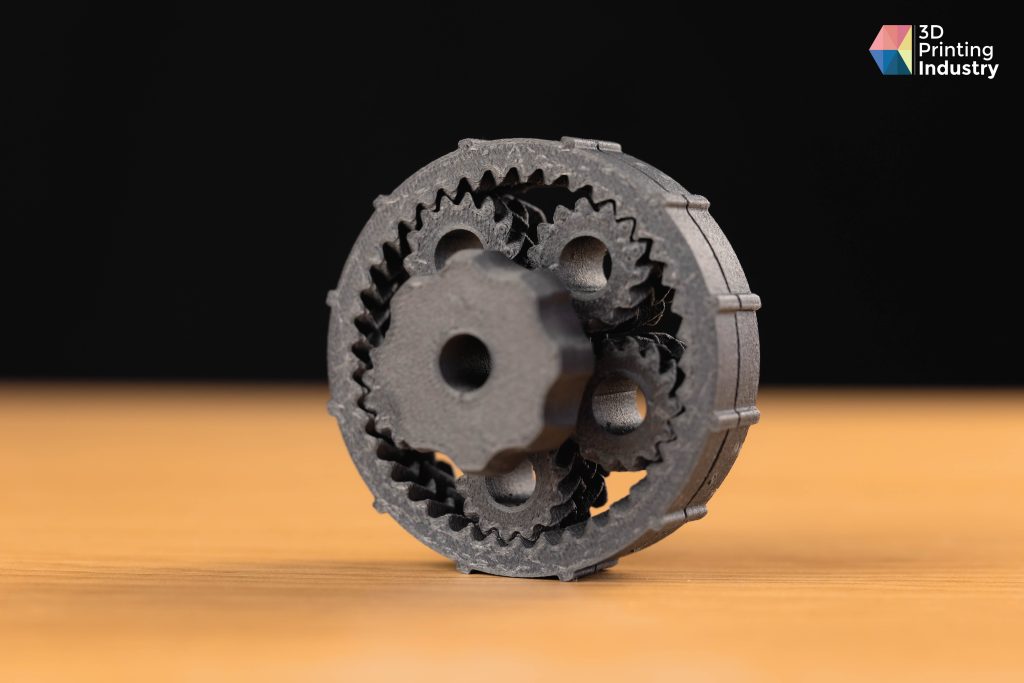

After this print we will move on to a staple feature of our testing: the nylon gear to integrate a mechanical system. Nylon (aka polyamide) is a popular material in the plastics industry, known for its strength and flexibility. One of the major difficulties with nylon filaments is that they are hygroscopic and easily absorb moisture from their environment. Printing nylon after it has absorbed moisture will cause several print quality problems. After the filament has dried thoroughly, we go to print. 245°C. So far, so good! We have absolutely nothing to report. The part is clean and smooth. On the positive side, we did not experience any warping. The part is totally usable.

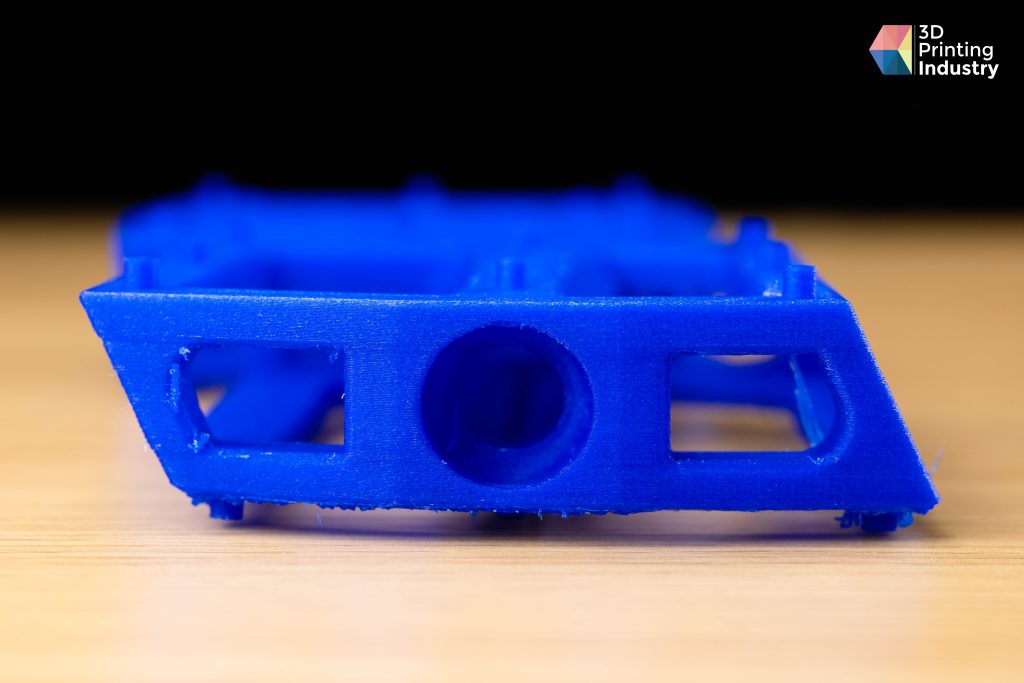

To continue in this vein, we are printing bicycle pedals in nylon reinforced with crushed glass fiber. Again, nothing to say except that the supports were quite difficult to remove. It’s all a matter of parameters. With a bit of patience and testing, you can get away with it.

Nylon model. Photos by 3D Printing Industry.

To finish with this printer, we will now print a modular shelf using different materials. For this, we will print the frame in PA12-CF, the boxes in PETG, and the fittings to fix the top of the cabinet in PLA-CF. If all goes well, we should be able to assemble it without any problems. And guess what? This is another success for this printer. All parts were printed without any problems, we only had some stringing with the PETG. To correct this, it will only be necessary to increase the retraction a little. The PA12-CF body is perfect, as well as the PLA-CF butterfly bars to attach the top plate to the cabinet body.

Modular shelving system model. Photos by 3D Printing Industry.

The verdict

We’ve come to expect great things from XYZprinting over the past few years, and the da Vinci Pro EVO certainly doesn’t disappoint in terms of print quality. Building on the success of the da Vinci 1.0 Pro, the system has kept what works and improved on the flaws. With a larger build volume, an enclosed build chamber, and high-end features like 100% automatic leveling and E-steps tuning, the da Vinci Pro EVO, priced at under 1399€, really does offer a lot without the high price.

In addition, the carbon fiber printing capabilities of this machine, thanks to the hardened steel nozzle, are truly something to behold. It’s rare to see a 3D printer of this price capable of printing composite parts of such quality, making it a very powerful tool to have in your workshop. This system is well-designed, easy to use, and offers excellent value for money. We liked the many material options and the ease of use of this printer.

Our tests revealed some minor drawbacks that did not detract from the overall experience. For the sake of completeness, we should mention that XYZprinting can always improve the user experience. The big weak point of this system is the slicer, between the bugs and the user experience, we are left wanting more. However, it’s software, and we are optimistic that the development team can make the necessary updates to make the user experience more pleasant. On the other side, the only hardware defect that caused us problems is the extruder. It would be nice to upgrade it to a dual-gear extruder, so there is no more slippage with the filament. Also, the extruder tends to degrade the filament by creating small dust particles. This dust got stuck with the filament, and the extruder become unusable. During the review, we had to dismantle the extruder four times to clean it so the printer could be used again. If the screw behind it is not tight enough the filament slips out, but if it is tight enough the filament degrades.

As far as print quality is concerned, the da Vinci Pro EVO is more than respectable for its price. It achieves excellent results in terms of repeatability if you exclude height measurements due to the first layer defect. The system has managed to make its way through our myriad of reference print tests and real-world applications without any problems. The surface quality offered here is excellent, and the parts are strong enough for real-world use.

Overall, the da Vinci Pro EVO has proven to be a formidable competitor in its class. The system’s Polycarbonate and Nylon printing capabilities make it an excellent choice for desktop users looking for a versatile 3D printing experience.

Technical Specifications

| Build volume | 220 x 200 x 200mm |

| Dimensions | 485 x 532 x 572mm |

| Weight | 24kg |

| Printheads | One |

| XY positioning precision | X / Y : 0.0125 mm |

| Max bed temperature | 110°C |

| Max nozzle temperature | 260°C |

| Connectivity | Wi-Fi, USB flash drive, USB cable |

| Nozzle diameter | 0.4mm |

Buy the XYZprinting da Vinci Pro EVO 3D printer here. The system is available to order now for 1399€.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the XYZprinting da Vinci Pro EVO. Photo by 3D Printing Industry.