3D Printing industry reviews the LulzBot Bio 3D bioprinter.

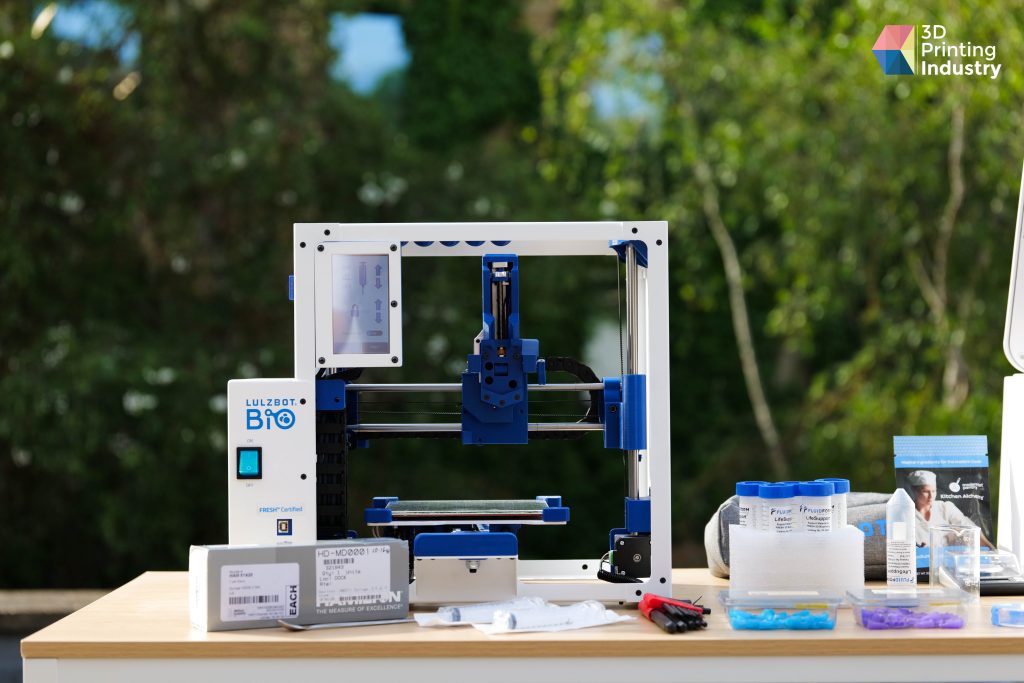

Designed by the US-based 3D printer manufacturer, the LulzBot Bio is the first and only 3D bioprinting system under the company’s signature LulzBot brand. The product line has been around since 2011, with a focus on open-source FDM 3D printers like the TAZ SideKick and TAZ Workhorse.

In line with the LulzBot ethos, the Bio is indeed another open-hardware machine – this time operating on the company’s Fluid Deposition Fabrication (FDF) bioprinting technology. The system is built for Freeform Reversible Embedding of Suspended Hydrogels (FRESH) printing, offering compatibility with everything from bioinks and unmodified collagen to alginate and other soft biomaterials.

As far as potential applications go, LulzBot has designed the machine for in-vitro pharmaceutical and cosmetic testing purposes, tissue engineering, regenerative medicine, and more.

Priced at a relatively affordable $9,950, the Bio is primarily aimed at researchers and educational institutions seeking a cost-effective entry to biofabrication.

A solid gateway to 3D bioprinting

LulzBot truly has placed accessibility front and center here, as the plug-and-play Bio comes complete with everything you need to begin 3D bioprinting. This includes sodium alginate printing material, Fluidform 3D’s LifeSupport gel medium, a syringe, 25 and 30-gauge dispensing needles, Petri dishes, specimen cups, and a plethora of maintenance tools.

The Bio itself is based on the cartesian axis system, a configuration known to be more rigid and accurate than a delta or CoreXY setup (albeit slower). On the build volume front, we have a 2.88L envelope measuring 160 x 160 x 89mm, which is ample space for a whole host of lab-based bioprinting applications.

Similarly, the compact 762 x 635 x 533mm operating footprint enables the Bio to easily fit inside laminar flow cabinets or on top of counters. Featuring a very LulzBot-esque full-metal frame, the system is rugged enough to be sterilized with both ethyl alcohol and UV lights.

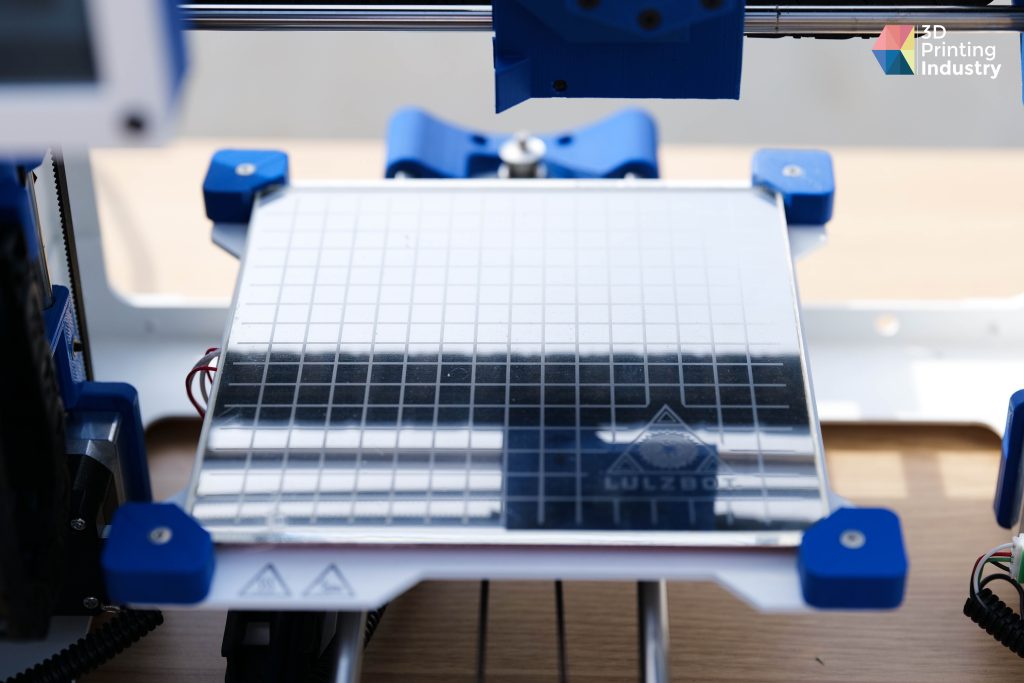

Looking at the build plate, we have a heat borosilicate glass print bed capable of maintaining up to 120°C. Though not obvious at first, a variable temperature heated bed is crucial in this case as it allows for full control of the printing conditions, ensuring biomaterial viability throughout the printing process.

On the electronics side, the Bio comes equipped with a 4.3” full-color touchscreen and a multilingual user interface. Here we can calibrate the printer, heat the bed, and control printing. The UI itself is crisp, responsive, and wrapped in a blue-based color scheme with an intuitive layout to boot. Connectivity options include a USB cable and an SD card. All in all, no complaints here.

The contents of the package and the build plate. Photos by 3D Printing Industry.

An open materials ecosystem

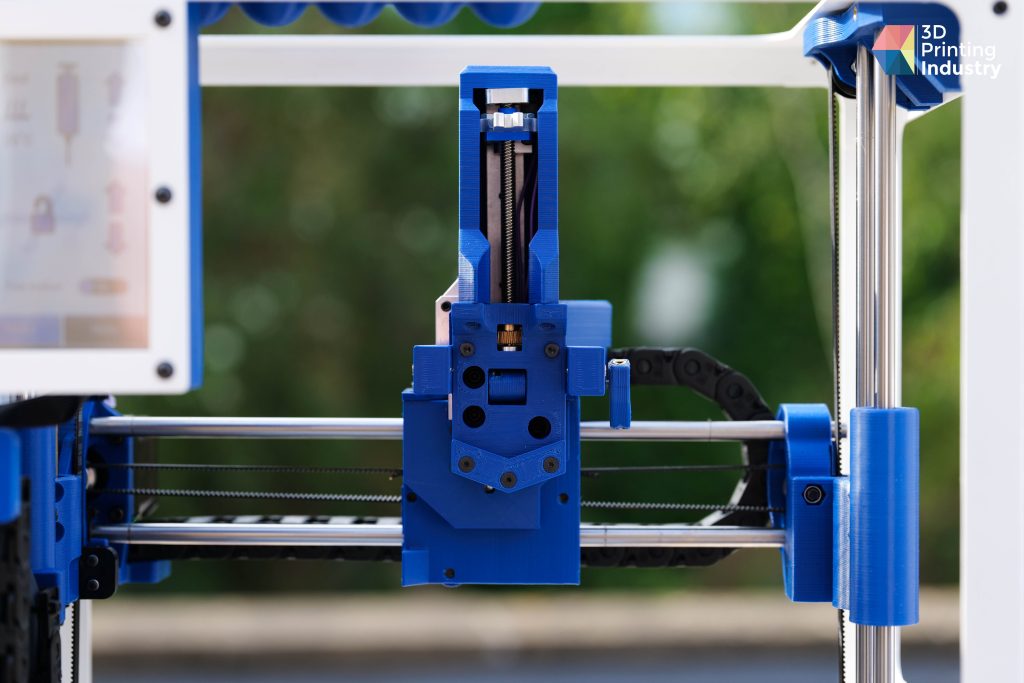

The Bio actually looks a lot like many of LulzBot’s original FDM 3D printers, except the filament extruder has been substituted for a dedicated Syringe Pump Extruder. The toolhead is compatible with 2.5ml, 5ml, and 10ml syringes, as well as 25 and 30-gauge dispensing needles.

While the Bio comes complete with ready-to-print profiles for alginate and unmodified collagen, it also sports an open materials ecosystem so it can be configured to dispense a wide variety of fluid-based inks. This includes photocurable resins, thermosets, silicone, and epoxies. For the purposes of this review, we’ll be focusing on the sodium alginate (printing material) and LifeSupport (suspensory gel/support material) included in the box.

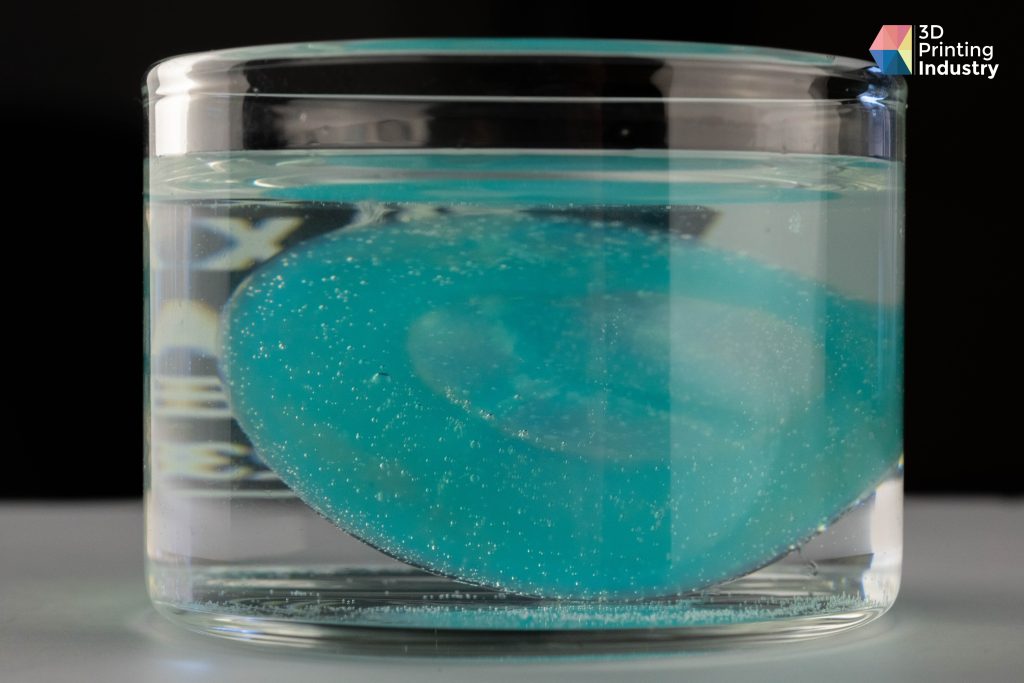

Sodium alginate comprises around 30% – 60% alginic acid and is a naturally occurring, edible polysaccharide found in the cell walls of marine brown algae. The hydrophilic material forms a viscous gum when hydrated, making the preparation of the printing material fairly simple.

To prepare the ink, we added 98ml of distilled water, 0.2g of alcian blue dye, and 2g of sodium alginate powder to a beaker. We then mixed the contents on a magnetic mixer to ensure homogeneity. After three hours of mixing, the sodium alginate bioprinting material is ready for use. Easy.

On the other hand, LifeSupport is a special-purpose support material designed to prevent bioprinted structures from collapsing and deforming during the printing process. In essence, it acts as a suspension matrix so soft hydrogel bioinks can be dispensed into complex geometries without the need for sacrificial support inks or ink modifiers that increase mechanical stability.

To prepare LifeSupport, we rehydrated the powder with 35ml of distilled water at a temperature of 4°C in the provided tube. We then shook the tube vigorously for a minute to ensure adequate mixing and let the compound stand for ten minutes to allow it to fully rehydrate. We then placed it in a centrifuge at 1000g to compact it down into the bottom of the tube. This is crucial as it needs to be in a gelatinous state to serve as a suspensory material.

Once printing is complete, the LifeSupport media is heated to turn it back into a liquid, which enables us to extract the printed sodium alginate structures with ease.

The LulzBot Bio’s printhead and printing materials. Photos by 3D Printing Industry.

The Cura LulzBot Edition slicer

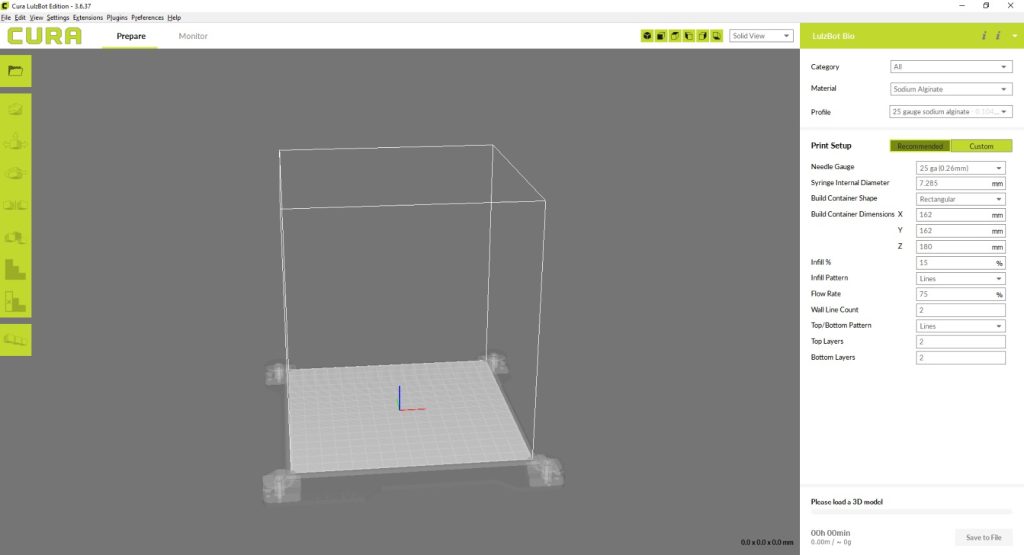

LulzBot provides its own free slicing software for all of its 3D printing systems, and the Bio is no exception. Based on the widely-used open-source Ultimaker Cura, the reskinned LulzBot Edition slicer offers all of the functionality you’d expect from any standard FDM print preparation software.

Much like the original Cura, the LulzBot Edition features basic translation, rotation, and resizing functions, all wrapped up in a digestible user interface. The motion system in use here is very similar to most other competitors on the market, so it’s simple enough to pick up with a few minutes of experimenting with the mouse.

After selecting the LulzBot Bio from the printers list, we found that the Recommended settings were more than enough to get started, which is perfect for beginners. There are a number of preset parameters available but the software also enables users to select the material, the needle gauge, as well as the syringe’s internal diameter. More advanced users will want to dive into the Custom settings, where the full suite of build parameters is unlocked.

Ultimately, the LulzBot Edition slicer does its job without any major shortcomings – it runs about as fast as the original Cura and maintains all of the core functionality.

Benchmarking the LulzBot Bio

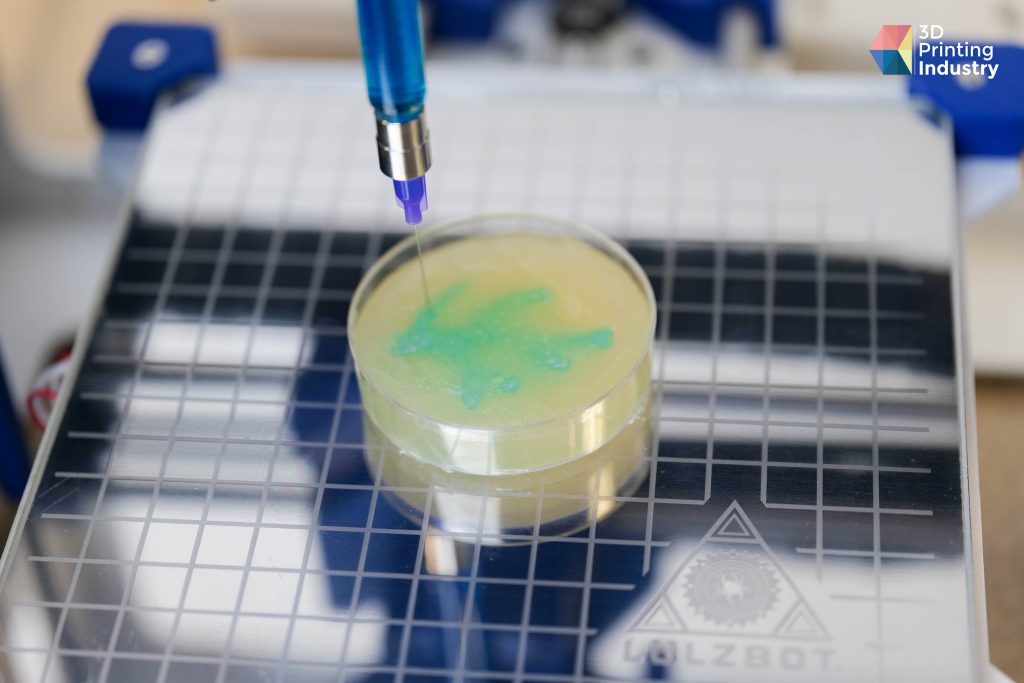

Now comes the benchmarking portion of the review, where we put the LulzBot Bio to the test with a set of bioprinting experiments. For our first build, we decided to jump right in and 3D print a right coronary artery using sodium alginate and LifeSupport.

First right coronary artery print test. Photos by 3D Printing Industry.

Perhaps unsurprisingly, the first print run was riddled with issues. We discovered that the LifeSupport gel we prepared wasn’t yet hard enough so the sodium alginate didn’t stay in place after dispensation. This resulted in severe distortion, leaching, and stringing between the branches of the artery.

This doesn’t mean we gave up, however, as we went back to the drawing board to fine-tune the setup process and re-do the build once more. In order to formulate a more viscous LifeSupport gel, we cooled the distilled water before mixing it with the powder, then let it stand for 15 minutes before running it through the centrifuge. We also used a new batch of sodium alginate for good measure, and decreased both the layer thickness and line width parameters in the printing process.

Second coronary artery print test. Photos by 3D Printing Industry.

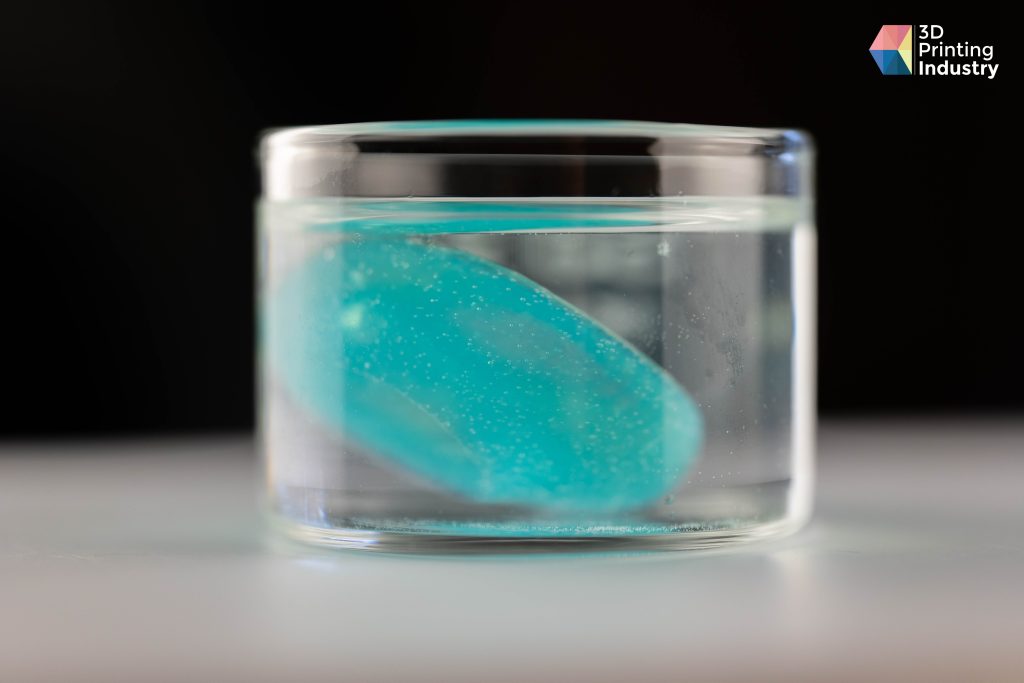

And it worked like a charm. Our revamped coronary artery turned out much cleaner than the first model, with no stringing or leaching anywhere. To preserve the print, we ran it through two baths to rinse it off and placed it in a solution of distilled water with 1% calcium chloride.

We then tasked the LulzBot Bio with printing a trileaflet heart valve, which has a much more complex internal geometry than the coronary artery. This build was also significantly larger than the first run, requiring two tubes of LifeSupport.

Trileaflet heart valve print test. Photos by 3D Printing Industry.

We’d perfected the prep and printing process by this point, so the heart valve turned out flawless. Despite the internal complexities of the model, the Bio handled the print with grace, delivering clean surfaces, smooth curves, and a distinct lack of defects. As far as print quality goes, this system is a winner.

There’s also something to be said about the sheer ease of use of this machine. To a newcomer, the bioprinting workflow might seem daunting but LulzBot has done an excellent job of crafting an accessible route to biofabrication. We found the operation of the system to be about as intuitive as a run-of-the-mill desktop FDM printer, so we have no doubt users the world over will have a breezy experience.

The verdict

When all is said and done, we were pleasantly surprised with the LulzBot Bio. A bioprinting system with such an attractive price tag will naturally ring some alarm bells, but we can safely say it makes for a great entry-level machine without sacrificing any of the core functionality.

Everything from the classic LulzBot frame to the clean and refined UI layout is well-designed, making for an excellent bioprinting experience. Ease of use certainly takes the spotlight here; users can jump right in without worrying about printer calibration, bed leveling, or any temperamental 3D printing materials.

As far as print quality goes, the Bio definitively held its own. Bar the first print run, all of our print tests were carried out successfully with excellent precision and defect-free surface qualities.

At the end of the day, we have here a very cost-effective 3D bioprinter. The LulzBot Bio is perfectly suited to universities and research laboratories seeking a budget-friendly tool to add to their experimental capacity.

Technical specifications

| Build volume | 160 x 160 x 89mm |

| Machine dimensions | 457 x 339 x 495mm |

| XYZ precision | 10, 10, 5µm |

| Max bed temperature | 120°C |

| Min layer thickness | 50µm |

| Min positive feature size | 80µm |

| Connectivity | USB/SD card |