Microscale 3D printer manufacturer Boston Micro Fabrication (BMF) has announced the closure of a $43 million Series C funding round.

Led by Chinese VC firm Shenzhen Capital Group Co. (SCGC), the investment comes at a time of significant growth for BMF, which has managed to double its global install base over the last year. Using the capital raised from the move, the company now plans to step up its expansion, by investing in product R&D and building out its marketing team.

“Our business has scaled strongly, and we plan to use new capital to further expand our capability,” said John Kawola, CEO of BMF. “Our global reach has been appreciated and valued by our customers, and our systems are now being used all over the world to both prototype parts that previously could not be 3D printed and drive end-use part production where conventional methods are difficult.”

Projection Micro Stereolithography

Co-founded in 2016 by MIT professor Dr. Nick Fang and serial entrepreneur Dr. Xiaoning He, BMF’s business revolves around its patented Projection Micro Stereolithography or ‘PµSL’ technology. Essentially a combination of SLA and projection lithography, the process sees flashes of UV light and custom optics used to rapidly photopolymerize layers of liquid polymer at a micro-scale.

Marketed through BMF’s microArch systems, the technology enables the production of high-resolution microstructures at a scale over 100 times smaller than a human hair. This is particularly true of the firm’s top-end microArch P130 3D printer, which can print down to a resolution of 2μm. But the company does also offer the less accurate P140 and P150 machines, for lower-resolution applications.

Thanks to the PµSL process’ broad material compatibility, with tough, elastic, casting and high temperature resins, BMF has previously highlighted its suitability for medical and electronics applications. However, the firm now says that “demand for parts on the millimeter scale, with micron level tolerance, is on the rise,” opening opportunities for it in product R&D, as well as research and short-run production.

BMF targets accelerated growth

Prior to the launch of its microArch machines, BMF’s operations largely centered on providing microscale 3D printing as a service. However, since the launch of its systems, the company has increasingly sought to expand its distributor network, as a means of getting them into the hands of more customers. Earlier in 2022, this drive saw BMF partner with Shree Rapid Technologies, which now ships them in India.

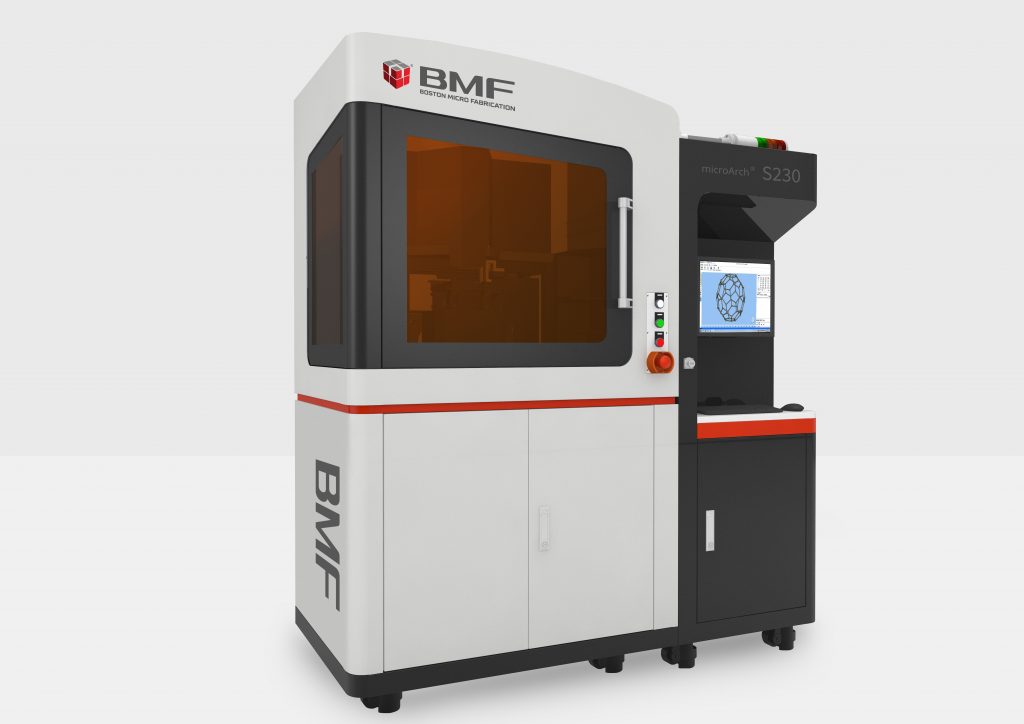

AXT also agreed to begin shipping the machines in Australia earlier this year, while the company itself expanded with new facilities in Boston and Shenzhen, and additional locations in Chongqing and Tokyo. Continuing this expansion on the machine front, BMF released its microArch S230 3D printer in late-2021 as well. At launch, the system was marketed as being five times faster than its predecessors, giving it the speed to drive the technology’s adoption in low-volume production.

These advances in both the breadth and scope of its offering have enabled BMF to continue addressing new applications with its technology. IPFL announced that it had become the first UK service bureau to offer microprinted parts earlier in 2022, following BMF’s reveal that Isometric Micro Molding would be installing microArch systems in January, to support clients’ design verification and prototyping efforts.

Over the last year, BMF has also worked closely with 4D Biomaterials to create implants at a microscale from the firm’s 4Degra bioresorbable 3D printing materials. When the companies announced a breakthrough in their research in December 2021, it was thought their approach could enable ‘PµSL’ technology to address everything from new micro-orthopaedic applications, to soft tissue research needs.

Following its latest round of funding, BMF says that it plans to continue to “expand and serve its global customer base” moving forwards, by ramping up its spending on product development, sales, marketing and customer support.

BMF’s microprinting competitors

While BMF has established itself as one of the early market leaders in the microprinting segment, it’s far from the only firm to be operating in this area. Two-Photon Polymerization (2PP) specialist Nanoscribe launched its Quantum X align 3D printer in January 2022, a system said to be capable of printing freeform micro-optical elements directly onto optical fibers and photonic chips with precision.

Similarly, UpNano announced the successful market debut of its inaugural 2PP NanoOne 3D printer a year earlier. Since then, the firm has moved into the bioprinting segment with the NanoOne Bio, a machine designed to enable the production of 3D tissue structures with living cells at a resolution ranging from the meso- to the nanoscale.

Elsewhere, Optomec has also patented the AJP 3D printing of 3D microstructures, a process that allows for the creation of parts with an accuracy of 15 microns. The technology, which is typically used to address electronics applications, is now part of the company’s IP portfolio, hence it’s protected across the US, Asia and Europe.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a row of BMF 3D printers at one of its facilities. Photo via BMF.