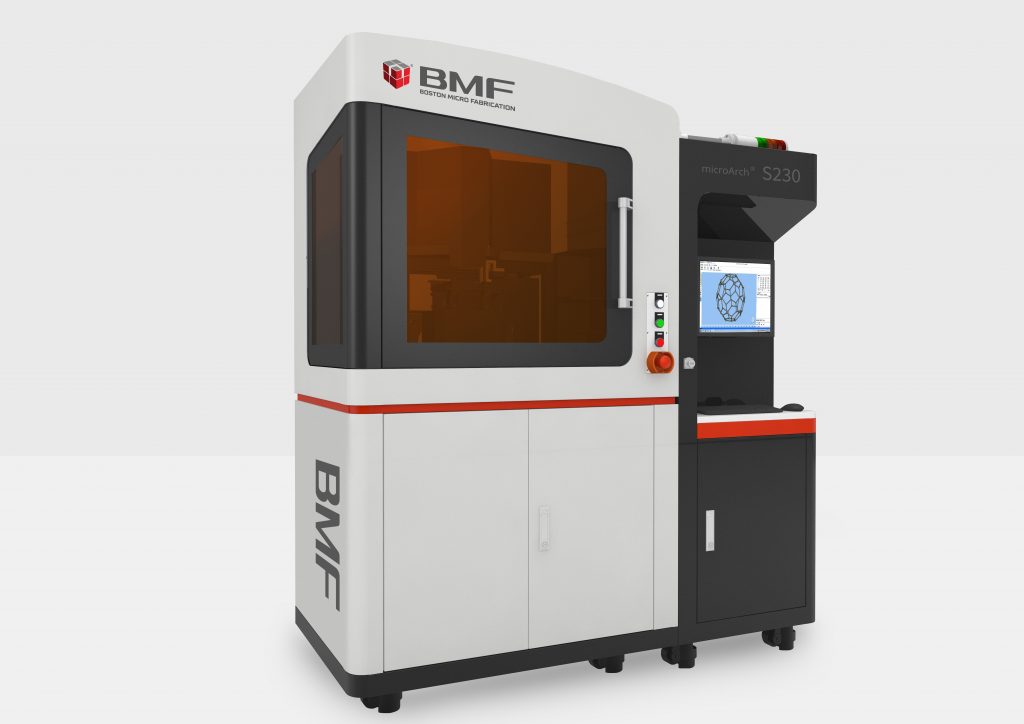

Microscale 3D printer manufacturer Boston Micro Fabrication (BMF) has unveiled a new edition of its highest resolution system, that it says provides an “unprecedented” level of print accuracy.

Known as the microArch S230, BMF’s latest microprinter is capable of producing parts at resolutions as low as 2μm, and at five times the speed of its predecessors. Thanks to these accuracy and throughput upgrades, the firm says that its machine could now help users to overcome the “technological barriers,” that have previously prevented 3D printing’s adoption within certain low-run production applications.

“As parts get smaller, they become harder to design, more expensive to manufacture, and generally more complicated to put into production,” said John Kawola, CEO of BMF. “We have changed that notion and brought 3D printing to industries that once deemed it impossible, and this new addition to our portfolio, will open even more doors for new applications on the smallest scale.”

“The miniaturization trend continues to dominate nearly every industry.”

BMF’s ‘PμSL’ technology

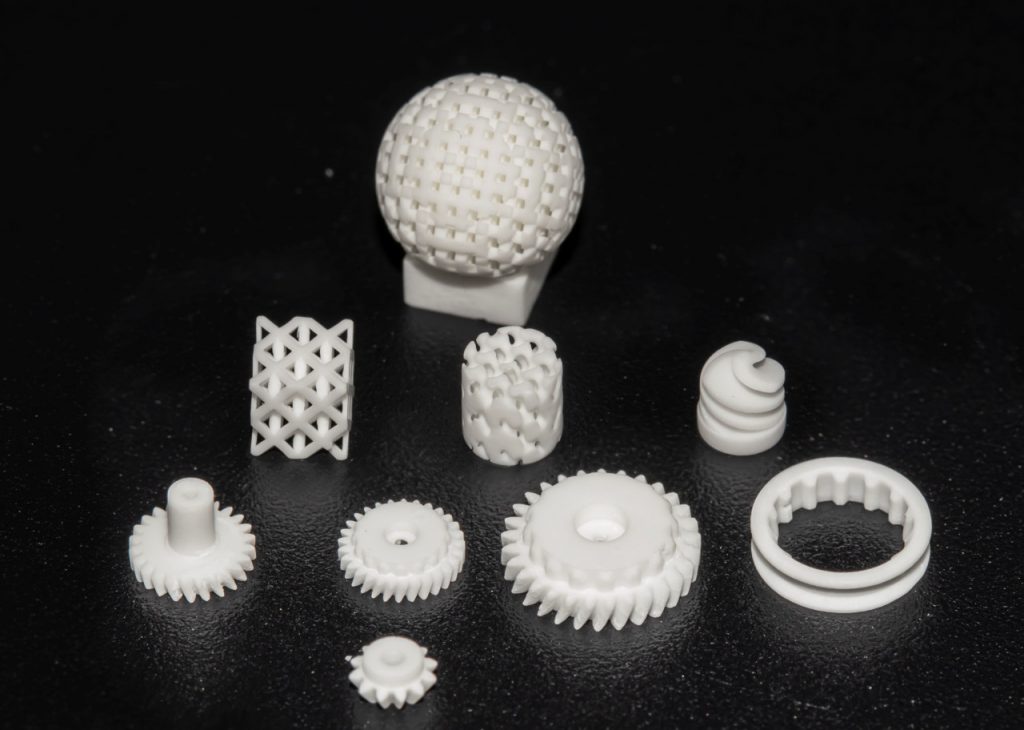

Each of BMF’s machines operate using its patented Projection Micro Stereolithography or ‘PµSL’ technology. In essence, the technique involves using a flash of UV light to rapidly photopolymerize layers of liquid polymer at a micro-scale resolution, yielding parts that are said to be of the same quality as injection molded or CNC machined counterparts.

In practise, the firm markets its technology through its range of microArch systems, which are capable of printing at three levels of resolution: 25μm, 10μm and 2μm. The fastest of these is the S240, a machine built specifically to yield higher part volumes, that was initially marketed as BMF’s ‘first and only’ short-run industrial 3D printer.

At 100 x 100 x 75 mm, the S240’s build volume remains the largest in the microArch range, but its resolution is capped at 10μm. With the S230, however, BMF has now reverted to concentrating on resolution, releasing a new entry in its ultra-precise 2μm range, that it says will help meet “rocketing demand” for intricate parts from within industries that were “once left out of the additive manufacturing landscape.”

A “next-gen” microArch

Built to provide a new level of part design freedom and resolution to researchers and manufacturers alike, the microArch S230 features BMF’s proprietary PµSL technology, albeit with a few upgrades. The machine’s 50 x 50 x 50mm build plate is much larger than that of the 50 x 50 x 10mm S130, while it’s said to be capable of printing up to five times more quickly than any of BMF’s prior 2μm models.

Weighing in at 670kg, the firm’s latest system is also heavier than its 390kg predecessors but its dimensions remain the same at 1720 x 750 x 1820mm, allowing existing microArch users to upgrade without sacrificing any extra floor space.

Elsewhere, the microArch S230’s active layer leveling and automated laser calibration capabilities allow it to deliver ultra-high resolution prints, while its capacity to process high molecular weight materials with viscosities of up to 20,000 Cp, mean that it’s compatible with an array of engineering and ceramic resins which yield more resilient end-use parts.

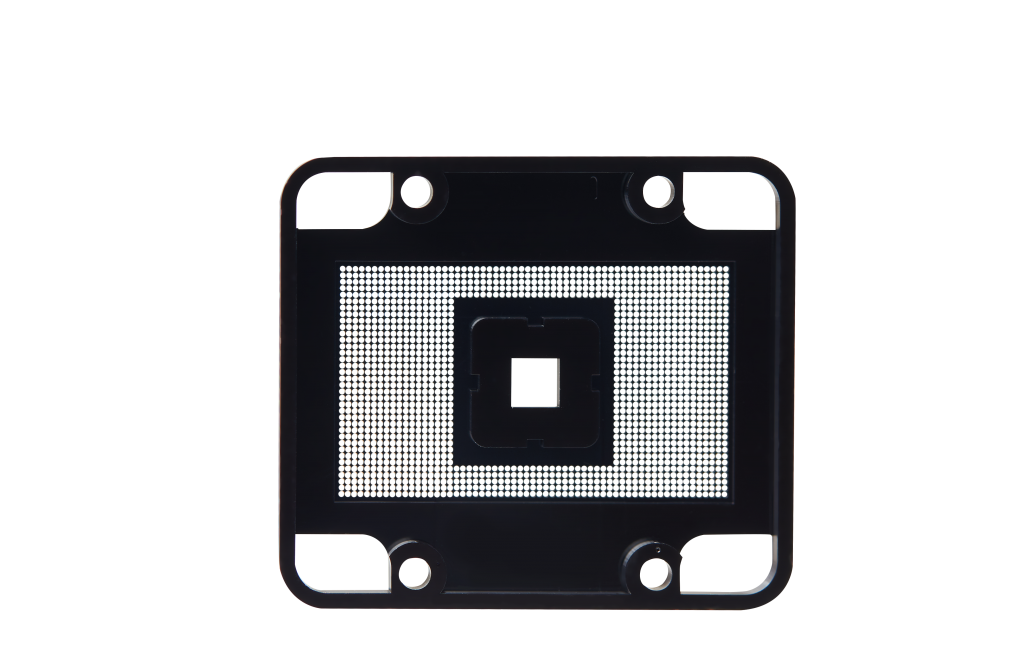

To help users take advantage of the S230’s new ceramic printing functionality, BMF has also released three tailor-made materials. With the ‘HT 200,’ the firm has launched a durable, high-temperature resin that can be soldered into electrical parts, while its Magnesium Titanate or ‘MT’ Ceramic features a high dielectric constant, making it ideal for producing components like antennas or waveguides.

Finally, BMF’s third new material is a biocompatible resin known as Alumina or ‘AL’ Ceramic, which is designed for high-stiffness applications including the production of tooling, casings, housings and medical devices. Thanks to the growing reach of its product portfolio, the company says that it has already managed to install over 125 microArch systems, since they were first launched in February 2020.

Moving forwards, BMF believes that the microArch has potential as a means of producing ultra-precise medical, microfluidic, biotech or electronic devices, and with ceramic specialist HRL Laboratories, it has found its first S230 client.

“As the first customer of the new microArch S230, we are excited to utilize the enhancements of the platform to increase our part capacity with the larger build volume and speed up our printing times,” said Toby Schaedler of HRL Laboratories. “We are looking forward to continuing to work with the BMF team and their line of micro-precision 3D printers to support our micro-part needs.”

“As a current BMF customer, we’ve been thrilled with the performance of our microArch S130 to support our work in micro-printing ceramics.”

Technical specifications and pricing

Below are the technical specifications for the microArch S230 3D printer, as well as its 2μm predecessors, the S130 and P130. Those interested in buying any of the machines can visit the BMF store page for a quote.

| microArch P130 | microArch S130 | microArch S230 | |

| Printing Material | Photosensitive Resin | Photosensitive Resin | Photosensitive Resin, Ceramic |

| Build Size | 3.84 × 2.16 × 10mm | 50 x 50 x 10mm | 50 x 50 x 50mm |

| External Dimensions | 1720 x 750 x 1820mm | 1720 x 750 x 1820mm | 1720 x 750 x 1820mm |

| Weight | 390kg | 390kg | 670kg |

| Input Data Format | STL | STL | STL |

| Certifications | CE | CE | CE |

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows BMF’s new microArch S230 3D printer. Image via BMF.