3D printing startup Azul 3D has announced the commercial launch of its first resin-based 3D printer, the LAKE printer.

Based on the company’s proprietary High Area Rapid Printing (HARP) technology, the DLP system combines a large build volume with a lightning-fast print speed to provide ‘unrivaled throughput’. According to Azul 3D, the debut machine can reportedly produce up to 2000x the throughput of comparable industrial-grade resin printers.

Additionally, the technology is also compatible with a wide variety of 3D printing materials such as rubber resins, high-temperature ceramic resins, flexible resins, and machinable resins. With such a versatile palette on offer, Azul 3D believes there’s something for everyone, including manufacturers in consumer goods, automotive, industrial tooling, and more.

“The LAKE printer will be game-changing for 3D printing,” said Chad Mirkin, Azul 3D’s co-founder and chair. “For the first time, we are combining throughput and materials at a price point that enables 3D printing to revolutionize many types of manufacturing. We have raised the bar in the industry, and this is just the beginning.”

High-speed resin 3D printing with Azul 3D

Azul 3D was originally a Northwestern University spin-out, where the HARP 3D printing technology was developed. Up until now, the firm has exclusively provided 3D printing-related services, including a ‘full-stack solution’ which entails design, materials selection, 3D printing, and post-processing.

The debut of the company’s first commercial product is aided by Azul 3D’s chemistry group, where all of the proprietary HARP resins are actually designed. Combined with LAKE, these materials enable a whole host of industrial and consumer applications.

Throughout the COVID-19 pandemic, the LAKE printer was used to print 1,000 face shields for healthcare workers every 12 hours. This equated to about eight face shields every six minutes on each of the company’s LAKE printers.

More recently, Azul 3D also partnered with sports products firm Wilson Sporting Goods. Working together, the companies created two new 3D printed pickleball paddle products. Designed to be fully customizable, these paddles can be integrated with advanced features such as dead spot removal, increased punch, and silenced ball hits.

The LAKE printer

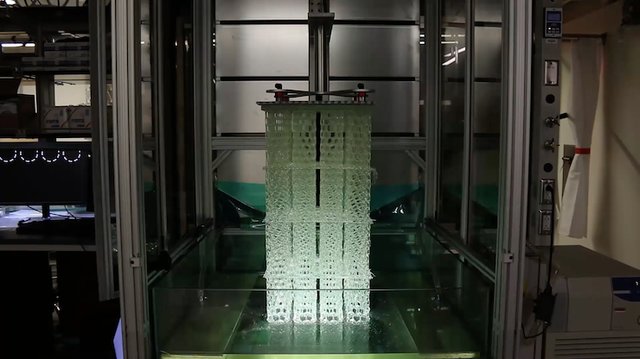

One of LAKE’s most noteworthy features is its tall-format build volume, which measures an impressive 254 x 305 x 610mm. The printer comes with a specially designed DLP interface that effectively dissipates heat, enabling the system to run large builds with high print speeds for long periods of time.

The system is also equipped with a high-intensity LED light engine with a resolution of 72 microns. The light engine covers around 16 million individual pixels without the need for ‘pixel shifting’, a technique used by other projectors to increase resolution.

Additional features include a clear UV hood that enables users to see inside the build chamber while blocking out ambient UV light and a large full-color touchscreen interface on the front.

“In the past year, manufacturers have been throttled by supply chain disruptions,” said Cody Petersen, CEO of Azul 3D. “At the same time, everyone is demanding more highly engineered solutions immediately. The LAKE printer offers a revolutionary solution to both problems and is the first step in industrializing additive manufacturing at scale.”

Azul 3D has also revealed that the LAKE printer is the first in a series of 3D printers set to be unveiled in the coming years. The next in line is named the SEA, and it will reportedly offer 4x the print area, enabling even larger part production.

Technical specifications and pricing

Below are the technical specifications for the LAKE printer. Azul 3D is now taking orders for LAKE, with deliveries expected to begin in 2022. Visit the Azul 3D website to receive a quote.

| Build volume | 254 x 305 x 610mm |

| Technology | DLP |

| LED resolution | 72 microns |

| Light engine wavelength | 385nm |

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a LAKE printer factory. Photo via Azul 3D.