3D Printing Industry reviews the LulzBot TAZ Workhorse 3D printer.

Designed by U.S.-based OEM Aleph Objects (now FAME 3D), the LulzBot TAZ Workhorse is a large-format FFF 3D printer running on open-source Marlin firmware. The desktop system is based on the previously released TAZ 6 but comes complete with several feature upgrades that set it apart from its predecessor. With a price tag of $2,950, the TAZ Workhorse is primarily aimed at prosumers, designers, and engineers seeking a reliable printing engine for the workshop.

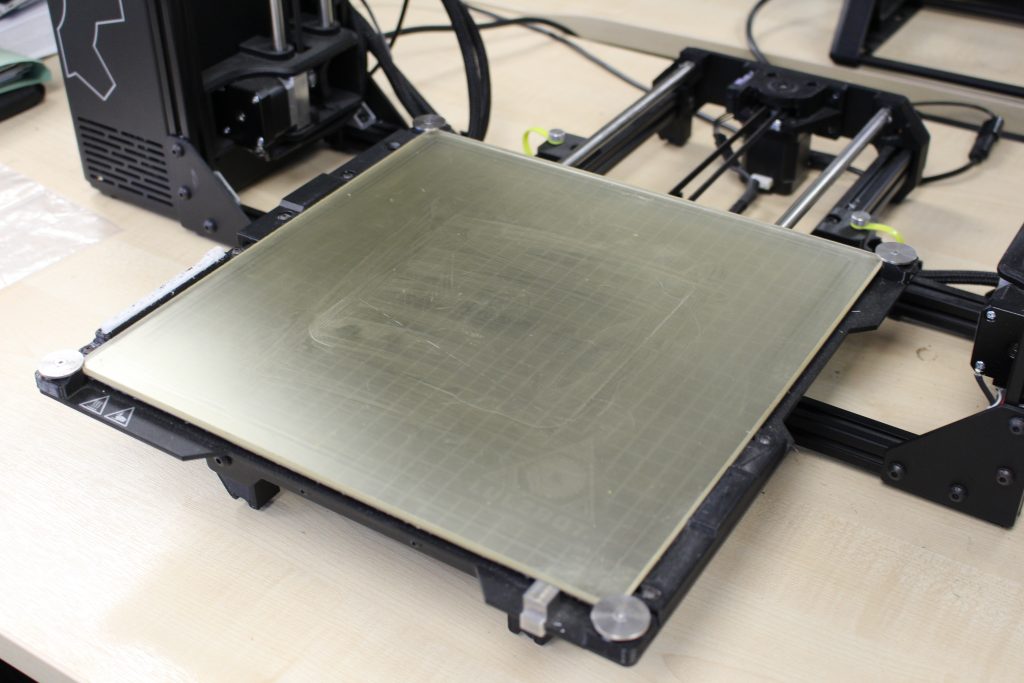

Defined by its unmistakable LulzBot open frame, the machine packs a build volume measuring 280 x 280 x 285mm, 14% larger than the TAZ 6. Users are provided with a removable borosilicate glass bed with a PEI coating on one side, which improves part adhesion. The maximum bed temperature clocks in at a respectable 120°C.

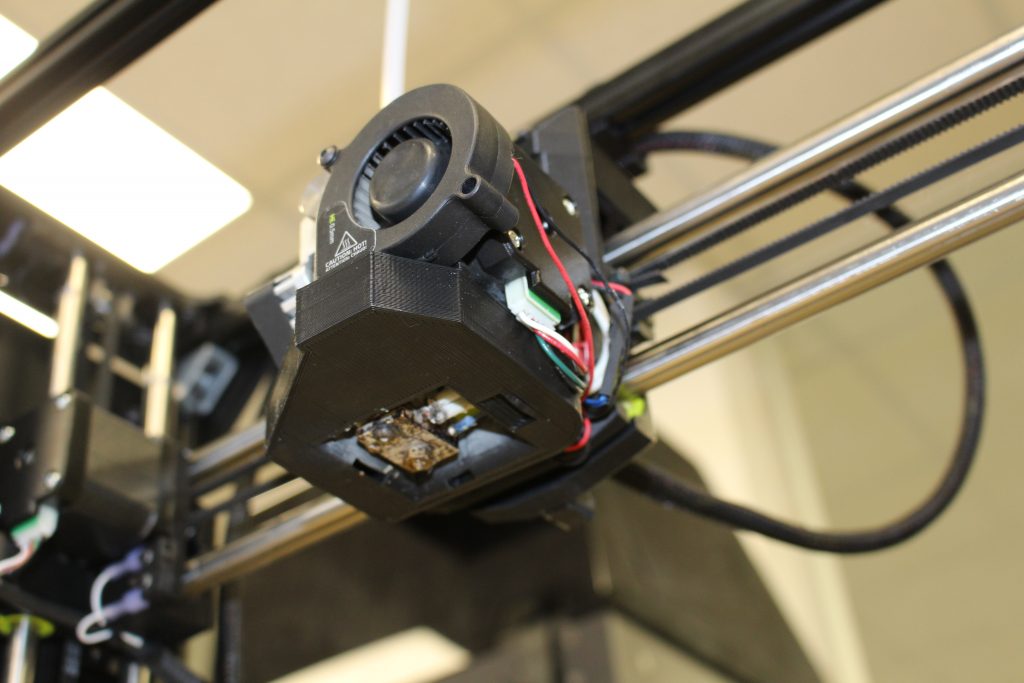

Looking at the system’s single printhead, we have a 0.5mm nozzle backed by a high-performance E3D Titan Aero extruder. With a maximum hotend temperature of 290°C, the company claims the desktop system can 3D print a whole host of filaments such as ABS, Nylon, Polycarbonate, and TPU. On closer inspection, you might notice that the printhead’s external casing is 3D printed, making for an optimized geometry with reduced weight and 360° part cooling.

Users are given a choice between USB and SD (an 8GB SD card is included) when it comes to connectivity. The 3.2” LCD screen, while not a touchscreen, provides access to all of the printer’s core functions, such as filament loading and bed leveling. As an aside, menu navigation is facilitated by a rotary knob, which gives it quite a ‘nuclear control room’ feel.

What sets the TAZ Workhorse apart?

The LulzBot TAZ Workhorse contains a plethora of noteworthy design considerations that it simply wouldn’t be fair to gloss over. First of all, it’s worth mentioning that the TAZ line goes against the status quo when it comes to filament sizes, so users will have to purchase 2.85mm filaments if they want to start printing upon unboxing. Luckily, another staple of the TAZ series is the ability to swap out the system’s printhead with ease.

Using the company’s universal toolhead adapter, users can substitute out the default SE toolhead for any of LulzBot’s other offerings. This includes the 0.5mm hardened steel HE toolhead for carbon fiber capabilities or the 1.2mm HS+ toolhead for thicker layer lines. The company has also now launched the M175 toolhead, which is compatible with 1.75mm diameter filaments, giving users the power to experiment with an extensive list of third-party materials.

The Workhorse’s powder-coated metal frame, which comes fully assembled, has been redesigned to provide improved stability compared to the TAZ 6. It makes use of smooth steel rods with self-lubricating linear bushings in a bid to deliver superior part qualities. As well as the reinforced mechanical components, the electrical elements in the printer have also been upgraded, which should help extend their service life.

Much like the other systems in the LulzBot line, the Workhorse also features the company’s signature belt-driven Z-axis. Although it may seem quirky at first, the design choice reportedly enables the printer to eliminate artifacts caused by the ‘Z-wobble,’ a problem synonymous with bent threaded rods.

Finally, the 3D printer features automatic bed leveling and a self-cleaning nozzle. While these aren’t exactly revolutionary on their own, the addition of LulzBot’s new proprietary X/Y/Z Backlash Compensation system might be. By measuring backlash using an internal calibration cube, the machine can compensate for any unwanted X/Y/Z shift during the automatic calibration process, improving dimensional precision and part surface quality.

The Cura LulzBot Edition slicer

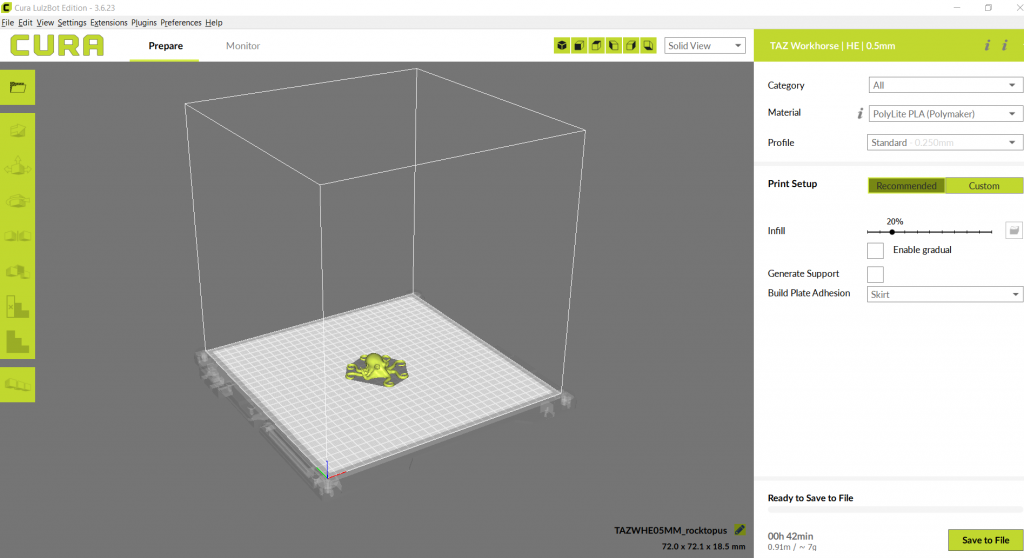

LulzBot provides its free slicing software for use with all of its 3D printers. Based on the widely-used open-source Ultimaker Cura, the LulzBot Edition slicer is an easy-to-use program that offers everything a 3D printing enthusiast might want, regardless of technical experience.

Donning the company’s acid green-grey color scheme, the slicer has an intuitive set of model manipulation functions pasted on a digestible user interface. The motion system in use here is very similar to most other FFF software on the market, so it’s a piece of cake to pick up with a few minutes of playing around in the menus.

Owing to the open materials nature of the company, the slicer comes jam-packed with a multitude of ready-to-use print profiles. In cases where the user might be required to tinker around with some of the print parameters, the Cura LulzBot Edition provides an extensive list of customizable settings. This includes temperatures, print speeds, infills, layers, and even tree-like supports.

All in all, the slicer does its job without any significant hiccups. We thought some individual setting menus could be optimized to make better use of the available space, but this is very much a design comment and doesn’t take away from the program’s functionality. Comparing its slicing speeds to the original Cura program, we can say that they’re comparable, so you’ll be spending less time prepping and more time printing.

Benchmarking the LulzBot TAZ Workhorse

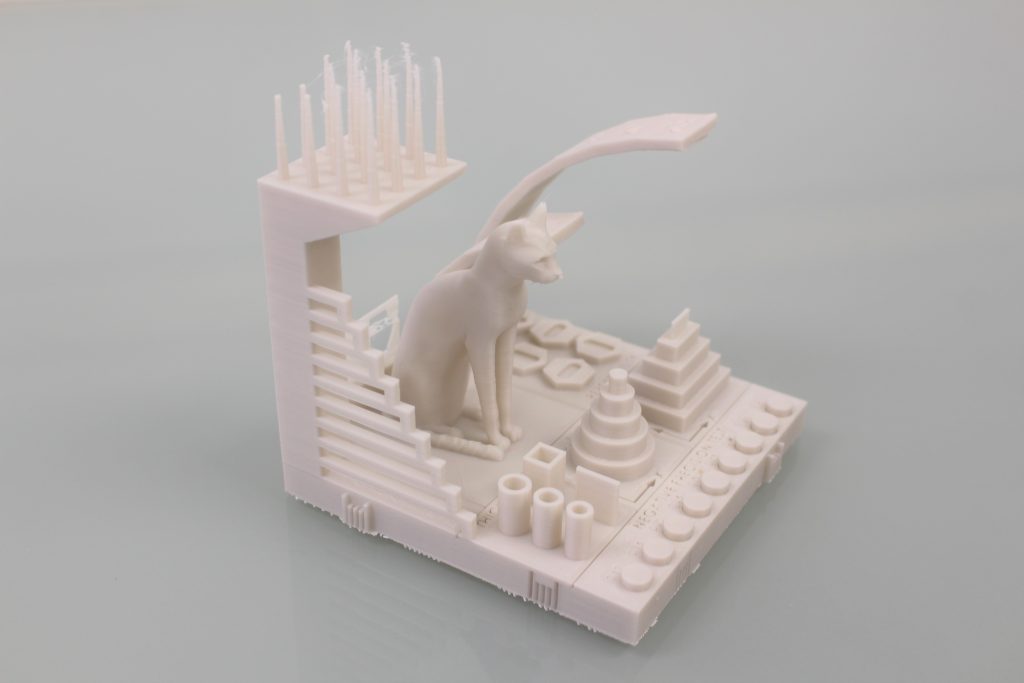

As always, we put the LulzBot TAZ Workhorse through its paces with our comprehensive set of 3D printer benchmarking tests. We kicked things off with 3D Printing Industry’s in-house benchmarking model in ABS. We use the benchmarking model to consolidate several smaller tests such as the overhang test, retraction test, and bridging test into one solid part.

Going into it, we admittedly had some concerns regarding the machine’s open frame, as higher temperature filaments tend to require a high level of temperature control to print successfully. That being said, the LulzBot held its own and managed to print defect-free overhangs up to 60°. As the machine-agnostic average is around 50°, this is a great result, especially considering the tricky nature of ABS filament.

We then looked at the bridging portion of the test, which involves printing horizontally into the void with no support structures. As such, the test is an excellent indicator of the extruder’s cooling system performance. Our horizontal structures started showing curves around the 35mm mark, a reasonably average result for systems in this price range.

Finally, we move on to the retraction test, which is designed to test the extrusion capabilities of the motors themselves. This is really where the Workhorse had its first hiccup, with significant stringing around the tips of our spike array. The result came as a surprise, to say the least, as E3D extruders tend to perform well in this category. Still, the fact that we were working with a nozzle temperature of 230°C undoubtedly had a significant effect. Regardless, the stringing wasn’t catastrophic, and it can be brushed off without affecting the rest of the component.

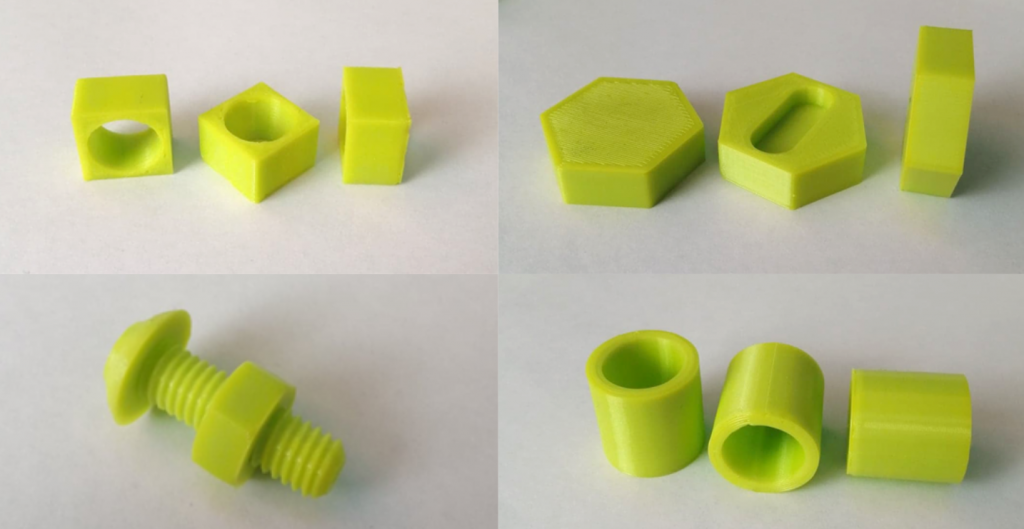

Next up was the mechanical assembly test, which gave us an idea of the dimensional precision of the LulzBot. In the case of the differential gear system below, the fluidity of the gears’ movements and the overall ease of assembly enables us to judge just how tight those tolerances are.

Our abundantly blue gear system worked like a charm. Each of the components had minimal surface artifacts, and playing around with the entire assembly yields no frictional resistance. We didn’t even have to go through any post-processing as the 3D prints’ contact areas were good to go straight off the build plate. The assembly as a whole would make a fantastic functional prototype.

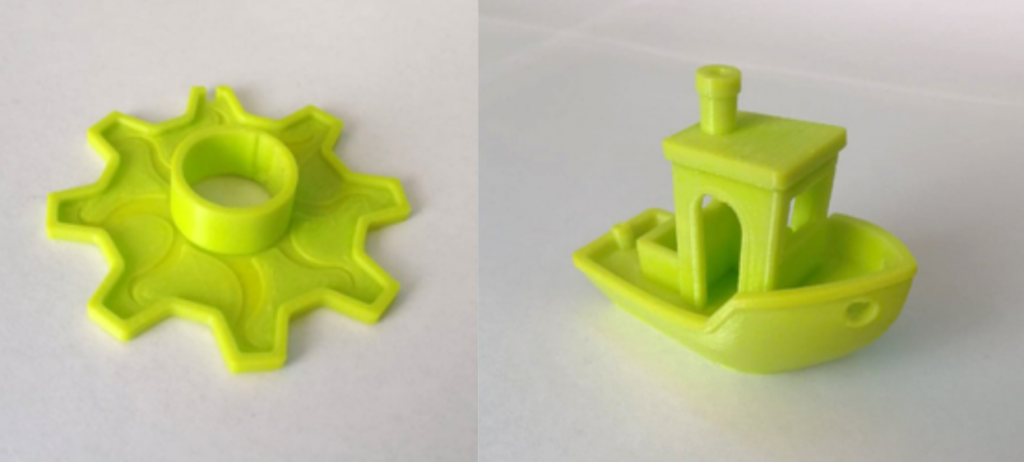

Finally, we decided to try our hand at some PETG prints, which gave us a chance to test the efficacy of the default print profiles made available to us on LulzBot’s Cura slicer. The models below are a standard 3D benchy and the test file provided on the printer’s own SD card.

Both parts came out exceptionally well with no stringing, surface defects, or warping issues. The layer lines are invisible, and the curved surfaces on both models are buttery smooth. This goes to show just how vital refinement is when it comes to print profiles, as 3D printing newcomers will be able to jump right in without worrying too much about the intricacies of various print parameters.

The verdict

We’re happy to say we were pleasantly surprised with the LulzBot TAZ Workhorse. It handles high-temperature filaments with grace for an open frame machine, and the modularity of the system’s components lends itself to some good old-fashioned DIY tinkering.

However, this isn’t to say we didn’t run into some behind-the-scenes hurdles, as the auto-leveling feature failed on us a few times. This was because the nozzle scrubbers did not fully clean off all of the hardened oozing on the tip of the hotend. We also thought the LulzBot could do with some Wi-Fi functionality, a touchscreen, and maybe even a filament runout sensor for the price.

Even so, the professional-grade print quality and large, robust bed allow for a myriad of functional polymer components. The LulzBot slicer does everything it claims to do on the software side of things, and the ready-made print profiles take the trial-and-error out of desktop 3D printing. The LulzBot TAZ Workhorse is a no-nonsense FFF system that would feel right at home in a workshop.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the LulzBot TAZ Workhorse 3D printer. Photo via LulzBot.