The 3D Printing Industry Awards 2022 shortlists are now available for voting. Who will win the 2022 3DPI Awards? Have your say by casting your vote now.

Sunlu is a China-based company founded in 2013, the company produces a variety of 3D printers and related technologies, including filament dryers & 3D pens. Sunlu products are built to a standard accepted within the price range and in line with the competition in terms of material usage.

They have recently released their newest Fused Deposition Modelling (FDM) printer the Terminator 3 which follows their previous 3D printer releases, the S8 Pro and S9 Plus. The S9 was sold with a Filament Dryer that fed material directly into the printer, this was a big selling point for its release. Sunlu is hoping to achieve the same success with the Terminator 3 using their new fast printing feature being released on the machine. This feature will enable printing at 250mm/s, 3x faster than the widely accepted standard of 50mm/s.

Released earlier this year, the Terminator 3 is manufactured in China alongside its desktop printer competitors but can ship to Europe as well.

Sunlu has brought out this printer to challenge other desktop printers in the budget range market. The company has included various features to make their printer more attractive to consumers such as the aforementioned fast printing. A BLTouch leveling sensor is also a huge advantage that this printer has over other similarly priced machines such as the Ender range.

These are all benefits for the Terminator 3 but Sunlu is not as established as Creality (Ender) and if you are searching for a high-quality workhorse machine then we would advise against Sunlu. The Terminator 3 is definitely worth the price tag, especially on sale, but where there are benefits there are also drawbacks as with any printer. As long as this is taken into consideration Sunlu could be an ideal choice for your next desktop printer.

During our review of the printer we tested using four primary criteria

- Repeatability, how well the printer can reproduce parts with identical geometry.

- Overhangs, how well the printer can handle overhangs, and at what angle they fail.

- Bridging, how effectively the printer can handle printing on no supports and at what distance they fail.

- 3DPI test, this is a purpose-built all-in-one stress test model that we put through all of our printers as a benchmark.

Supplemental testing includes assessment of advertised features. For example, we also tested the machine’s print speed features as this is one of the main selling points that Sunlu advertises.

Key features & selling points

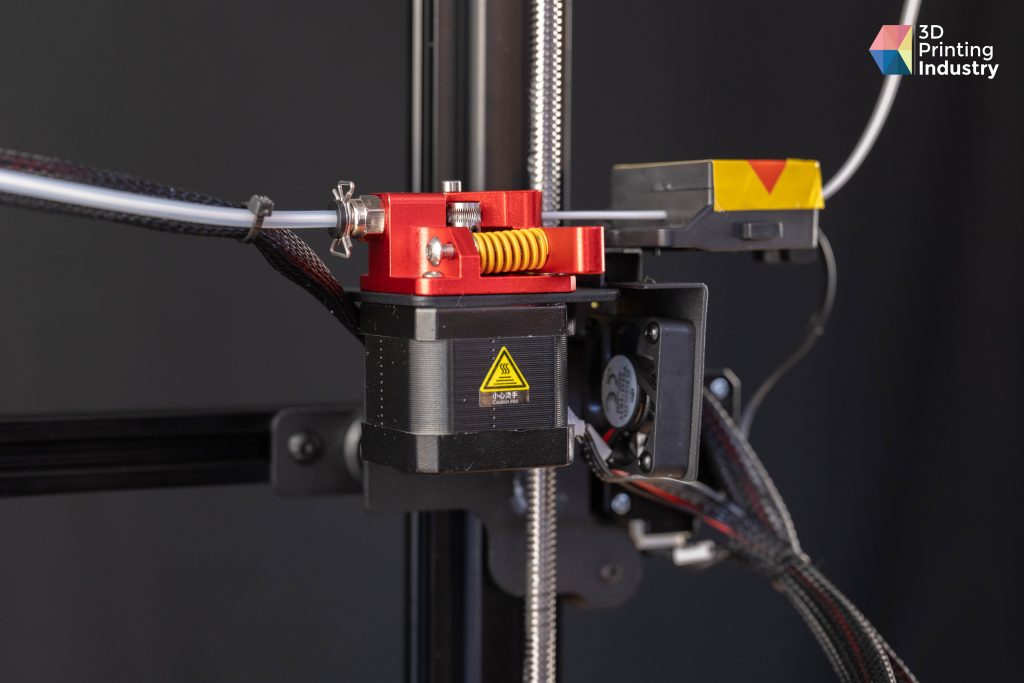

One of the key features of the Terminator 3 is its fast print option. This toggles on and off in the printer’s menu and has no relation to the slicer or sliced .gcode file. As far as we can tell the printer accomplishes this by multiplying the gcode speed and increasing the nozzle temp allowing better flow rates to account for the increased movement.

Another great feature of the printer is the BL touch sensor installed on the printhead. This requires very little tuning and once the Z-offset is correctly calibrated, the sensor replaces the necessity of manual leveling that a lot of desktop printers require before every print.

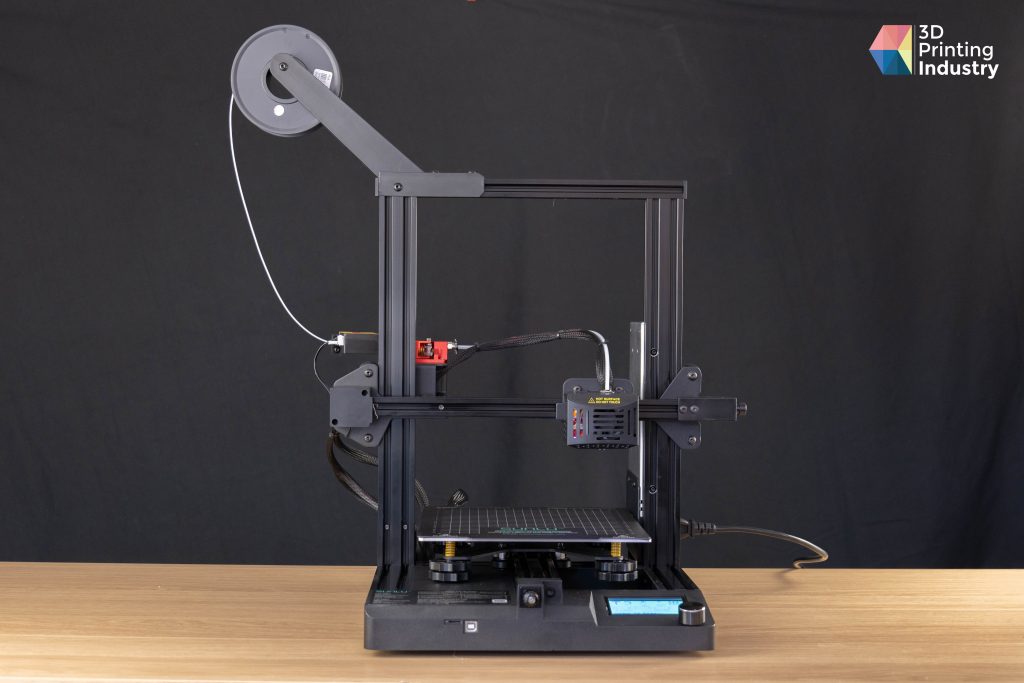

In other ways, the Terminator 3 is very similar to its competitors as it is made from the same aluminum square extrusion that’s frequently used in low-value machines due to its weight and ease of assembly. Build volume on the printer is also average for its size, sitting at 220 x 220 x 250.

The Terminator 3 relies on a bowden extrusion system which comes with its own set of positives and negatives. As the printer is heavily focused on speed, this has proven a wise choice. A direct drive system which sits on the y-axis above the printhead would create too much inertia for an accurate print at 250mm/s speed. The cons of a bowden extrusion system is that it cannot print specialized materials such as flexible and composites without considerable extrusion issues due to the retraction drive being so far from the nozzle.

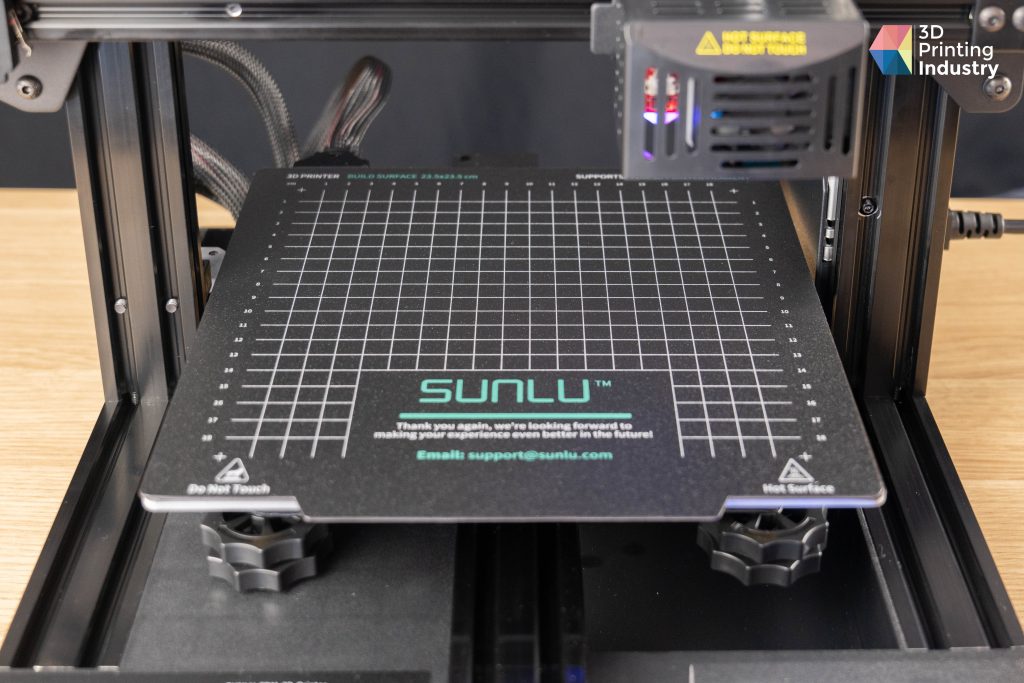

A magnetic bed rather than glass is used for this printer and we have had no issues with this during our tests despite many claims that glass beds are the superior material. This also means that prints can be easily removed by bending the bed resulting in the parts coming loose.

For a $300 printer, these qualities are quite acceptable, but if we were to recommend this printer to anybody specifically it would be a beginner or someone with limited 3D printing experience to learn how to use the machines and eventually move on to a more professional grade printer.

This printer would be perfect for a school workshop where it is constantly being used and tested by inexperienced designers. The quality of parts will stand up to use by these markets and we think this is a perfect area for sunlu printers to be marketed towards.

First Impressions/Unboxing

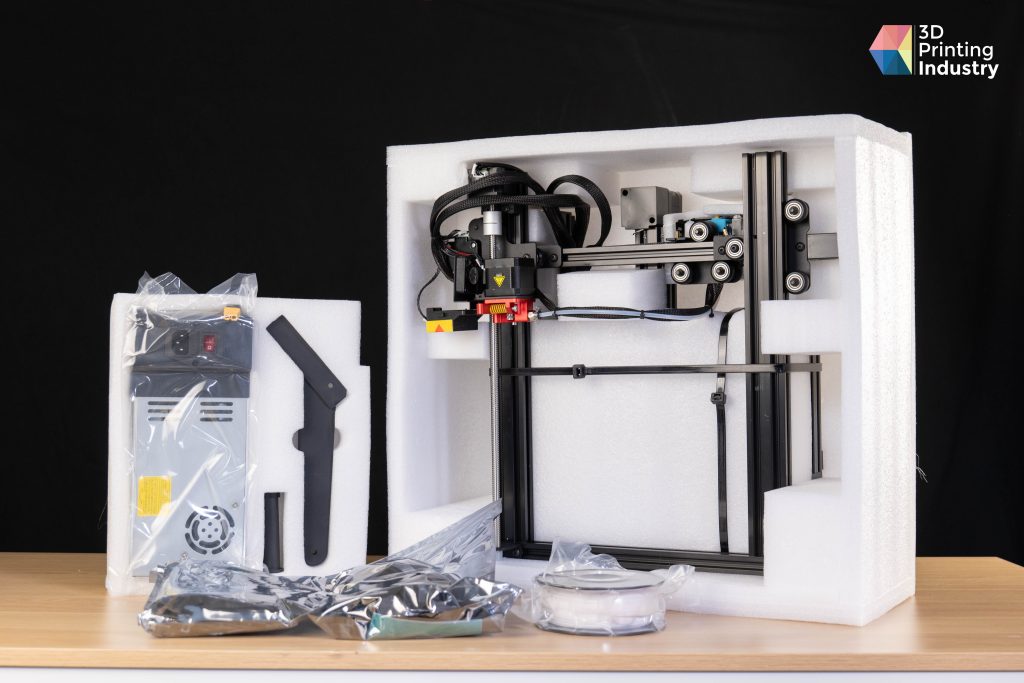

The printer was packaged securely and came in 3 main sections, the body, the z-axis with printhead attached, and the power supply, plus miscellaneous pieces. The Terminator 3 comes with all the usual peripherals including a small roll of filament, a print scraper, a filament cutter, and all the tools necessary to construct & maintain the printer.

The 3 parts were extremely easy to assemble, thus there was no issue with this. Our engineer had the terminator 3D printing within 20 minutes of opening the box.

The first print was the test file that came with the printer. The test files are usually optimized for the machine and are used to showcase the quality it can produce given the perfect parameters. The model, as shown below, printed well, although the layer lines are quite visible.

Software options

Cura is the recommended software to use with the terminator. Sunlu has provided a profile that can be downloaded from their website. Cura is a user-friendly slicing software as it can be utilized with minimal settings for a beginner or can be used in “expert mode” where the technical options are made available. Other software can be used with the printer of course but many people are already familiar with Cura.

3D Printer Benchmarking

Basic testing started off with a benchy print, this performed well and gave accurate results with a mean difference of 0.1515mm. Our measurement devices are accurate to ±0.015mm. To get this result we measure the printed part and compare it to the model diameter. For the price of the printer, this is an impressive result. After the success of the benchy, we printed some more precise models to show us more focused results.

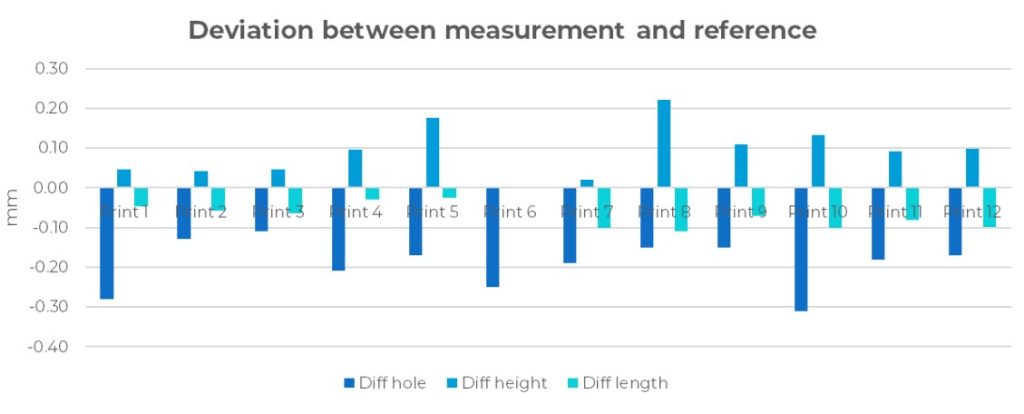

The first of the tests was printing square parts with a circular hole in the middle. This is to test whether the filament is extruding past the model parameters and therefore lessening the diameter of the hole.

The mean difference for all three ratings of the square part test is 0.115mm (over 0.10mm) and the standard deviation is 0.0533mm (almost under 0.05mm). The results show the weakness of the printer in this test is the hole φ. The standard deviation is 0.060 for hole φ which is higher than what you would hope for with this printer. On average the hole φ is 0.19mm less than it should be in reference to the model.

The printer scored similarly on the other repeatability tests and the overall results were quite average for a printer of this standard. The mean difference for all measured dimensions is 0.0769mm. This is under the reference of 0.1mm that we expect. The standard deviation for all dimensions is 0.0524mm which is above the reference of 0.05mm. This means it is slightly weak in this area but not by a significant margin.

The main area that lets the Terminator 3 down is the internal dimensions of the printed models.

Compared to other machines in this price range these results do not stray too far from expected. With extra tuning and care, this printer could be made more precise.

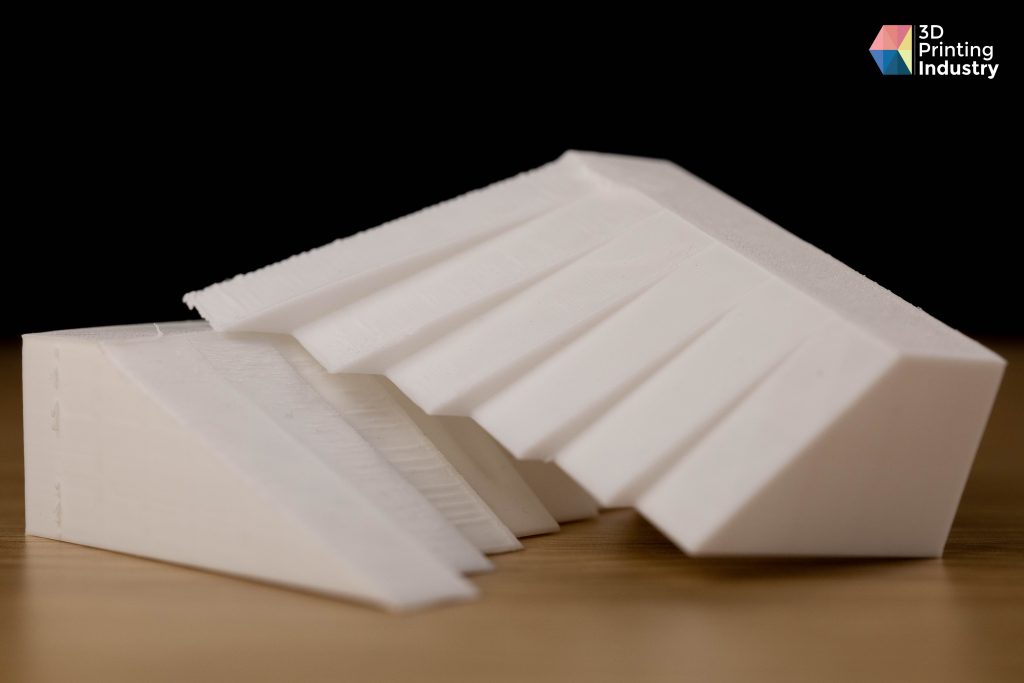

Bridges & overhangs are another area where we test printers’ limits. This shows us the cooling ability of the printer as the faster this is, the better the surface finish will be under the bridge. The Terminator 3 scored fairly low in this area compared with other printers of this style. The printer would benefit from a 360° fan duct which would circulate air around the nozzle much more efficiently.

Speed Print testing

The speed print feature of the Terminator 3 is the main selling point advertised on the Sunlu website. This addition is useful as it allows the user to produce rapid prototypes of parts without having to wait hours for a print to complete.

In our experience with the speed mode, it has good potential for producing quick and rough parts but it is not suitable for mechanical components or parts with lots of details. Bulging occurs on the corners of models and this would affect any interaction or movement where the model needs to be dimensionally accurate. For this reason, we recommend fast print for novelty or aesthetic prints rather than functional or mechanical models.

The Terminator 3 also suffers from under-extrusion within the infill of parts. This is a huge downfall for the printer as this will affect the structural characteristics of a model. We were quite disappointed with this result as up until this issue was made prominent, we were quite impressed with the printer.

How does the Terminator 3 measure up?

Building on the previous mentions of under-extrusion there were a few more issues we had when testing this printer.

During our various benchmarking prints we purposefully cut the filament short to test the filament runout sensor and were met with disappointing results as the machine kept printing 2-3 layers before pausing to warn us it had run out. If we had then loaded filament back into the machine it would have resumed the print on the wrong layer ruining the print and then wasting filament on the resumed section.

These were the main two problems with the machine, the third being quite a small bug in comparison. When starting a job the printhead will plot 16 points on the bed and come to rest on the top right corner. The bed is then fully extended forwards while heating, this then blocks the screen meaning you cannot tune any of the settings. This is a small issue but quite an annoyance if you want to change the temperature or turn on fast print before your part starts printing.

Our overall verdict for the Terminator 3 is positive. The desktop 3D printer performed well in all our tests and is a good choice for a beginner or seasoned 3D printer enthusiast. The price range of roughly $300 is acceptable for the machine you receive.

The works well and is much quicker to set up and use than its competition. The leveling capabilities are also very impressive for a cheap printer and once we had set the correct Z-offset we didn’t have to touch the leveling for any of the parts we printed during our testing. Under-extrusion was witnessed on many of the models during printing but once it had finished the walls there was no issue with the final piece other than internal strength inconsistencies.

Sunlu could rectify this issue by editing the Cura profile which we recommend they do for the next batch released.

The malleable plastic bed aided with removing parts from the print surface and made cleaning of glue a much simpler task. Glue was used with prints with large surface areas and with filaments such as nylon which are notorious for unadhering during printing.

The printer has no major faults but seems to have an issue with under extrusion within the infill of models this could jeopardize strength in parts that need to maintain structural rigidity. Certain features could be amended to make this printer more user-friendly such as the aforementioned position of the bed when heating.

The printer has a healthy appeal for a desktop user after an entry-level printer that is reasonably “plug & play”.

The Sunlu Terminator 3 is a good printer, around average in terms of accuracy compared to other printers in the same market range. If Sunlu continues to improve its printers, they will be a great choice for your next purchase.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Sunlu Terminator 3 3D Printer. Photo by 3D Printing Industry.