The 3D Printing Industry Awards 2022 shortlists are now available for voting. Who will win the 2022 3DPI Awards? Have your say by casting your vote now.

Canadian 3D printing powder developer Equispheres has launched a new, safer-to-handle aluminum feedstock at the Formnext trade show.

Designed specifically to enable the safer, high-throughput 3D printing of aluminum parts, Equispheres’ NExP-1 material is unusual in that it’s dust-free. As such, the powder has the functionality of its competitors, while also being characterized as non-explosible as per ASTM standard E1226, making it less susceptible to flash fires or explosions.

“We have achieved these key safety properties without altering the quality of our material nor the chemical composition,” said Evan Butler-Jones, VP of Product & Strategy for Equispheres. “In printing, this material performs just as well as our other aluminum powders, but it has the added benefit of being non-explosible and non-combustible.”

Equispheres’ powder portfolio

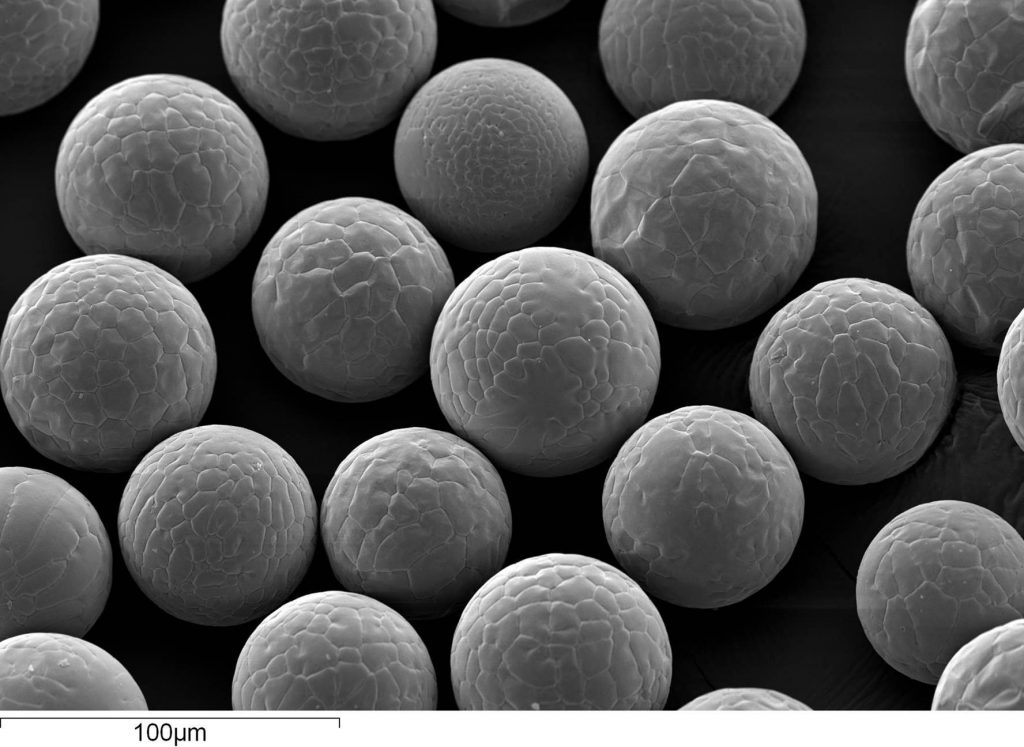

Equispheres was established in 2015 with the goal of developing high-performance metal powders that help realize 3D printing’s throughput, consistency and cost efficiency potential. In the manufacture of its materials, the company uses a unique atomization method that’s said to yield perfectly spherical powders, which in turn have the uniformity to ‘open new opportunities for high-volume, lightweight parts.’

To ensure its materials are capable of effectively meeting end-use applications, Equispheres often develops them alongside industry partners, with its previous collaborators including TRUMPF, Lockheed Martin and Aconity3D.

The company has also raised a significant amount of funding towards the development of its powder atomization technology. Following Equispheres’ $30 million Series B funding round in April 2020, it raised another $3.5 million via the Federal Economic Development Agency for Southern Ontario earlier this year, capital it has used to ramp up powder production.

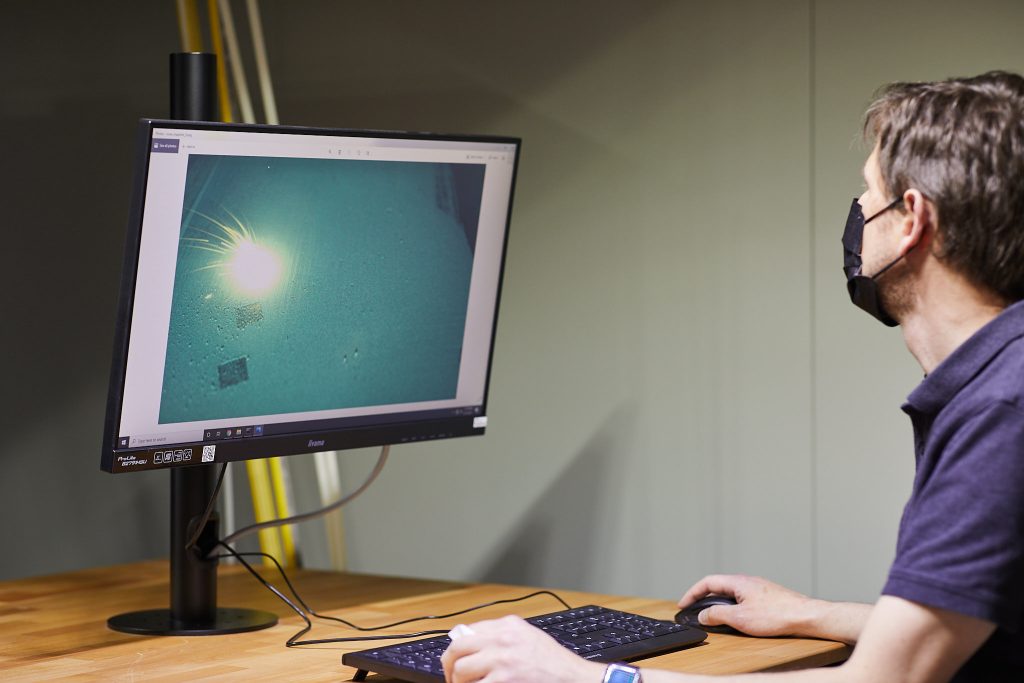

Elsewhere, the firm has utilized this funding to expand its lab facilities as well. In late 2021, Equispheres acquired a 1000W laser Aconity3D 3D printer to aid its process R&D, as well as a GranuTools GranuCharge system, designed to measure the electrostatic charge created within flowing powder, to improve its QA workflow.

The novelty of non-explosible aluminum

As metal 3D printer users will no doubt be aware, alloys like titanium and aluminum need to be handled carefully, as they can combust extremely quickly when exposed to air in an enclosed space. This hazard is particularly pressing in 3D printing considering the dust often created during processing, hence powder management has become a critical (but sometimes laborious) part of users’ workflows.

To help put such manufacturers at ease about the risks associated with handling aluminum, Equispheres has launched an innovative new non-explosible AlSi10Mg material. The alloy has not only passed the ASTM E1226 Standard Test Method for the Explosibility of Dust Clouds, but been deemed non-combustible, as per the UN Manual of Tests and Criteria, Part 3, Subsection 33.2.1. for flammable solids.

According to the firm, the powder “reduces the hazards of day-to-day handling without sacrificing the quality of the printed part,” in a way that could effectively lower one of the barriers to deploying 3D printing in industrialized settings.

“We are applying our technology to empower innovation in additive manufacturing. We anticipate this new safer aluminum material will be embraced by companies using AM in a production setting,” added Kevin Nicholds, CEO of Equispheres. “This new breakthrough is a result of our ongoing efforts to make 3D printing more accessible and competitive with other manufacturing methods.”

Follow this link for all the Formnext 2022 news.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

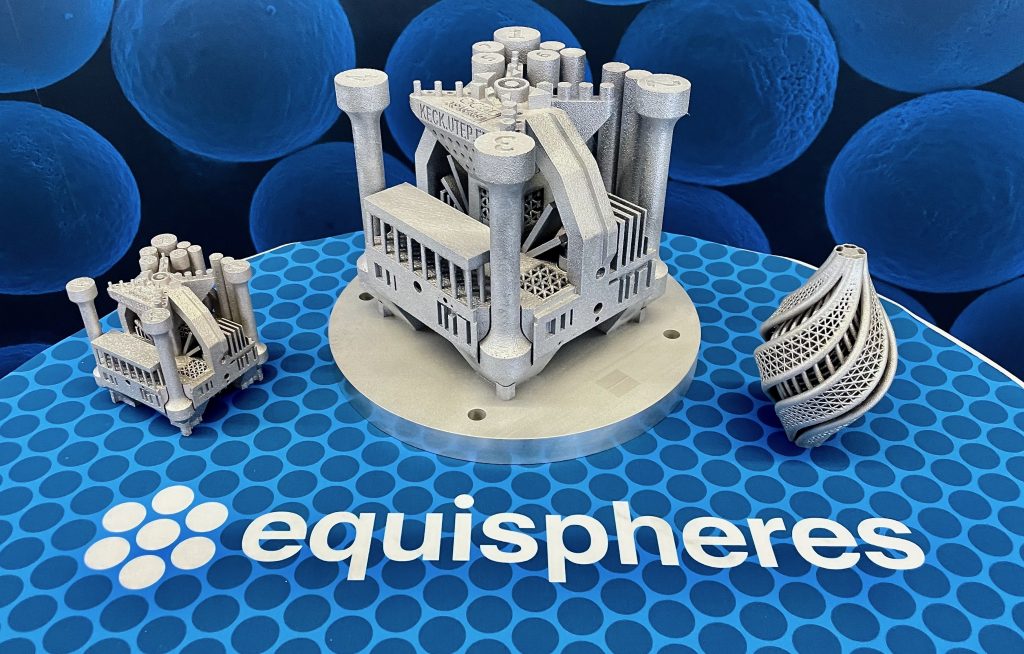

Featured image shows a set of prototypes 3D printed from Equispheres’ NExP-1 material. Photo via Equispheres.